Waste building mud sand washing treatment system

A water washing treatment and building technology, applied in the direction of filter screen, grid, wet separation, etc., can solve the problems of reducing sand washing efficiency, adhesion, difficult discharge, etc., and achieve the effect of improving sand washing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The following is attached Figure 1-5 The application is described in further detail.

[0067] The embodiment of the present application discloses a water washing treatment system for waste building mud and sand.

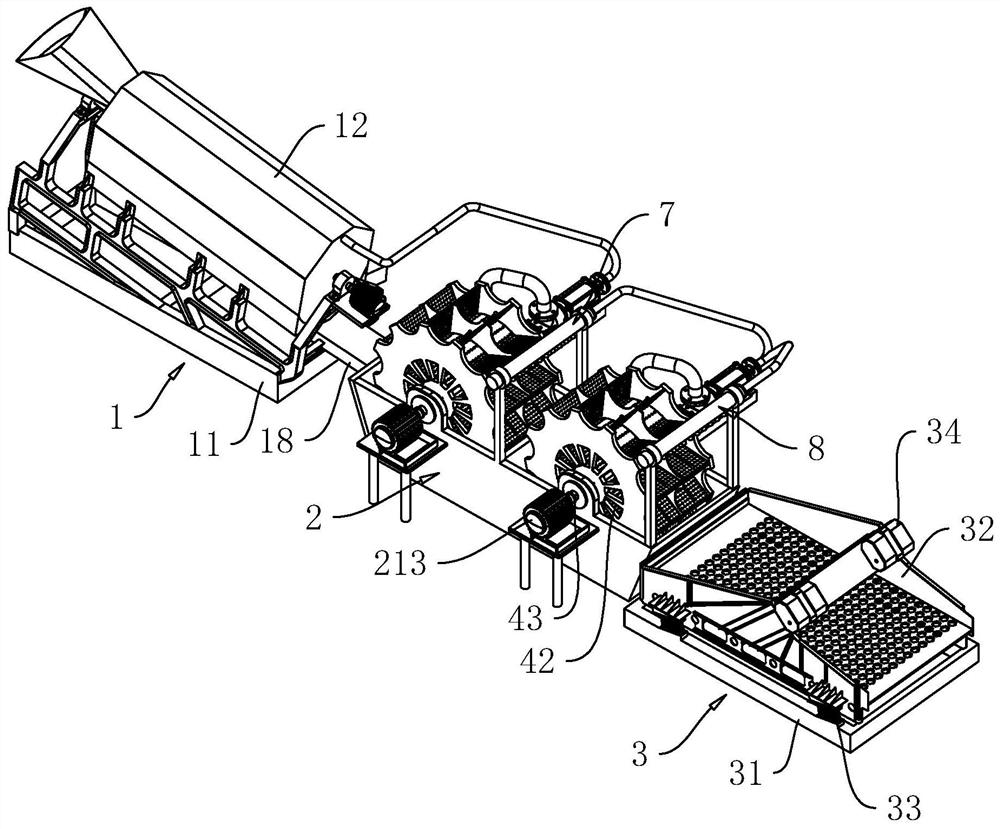

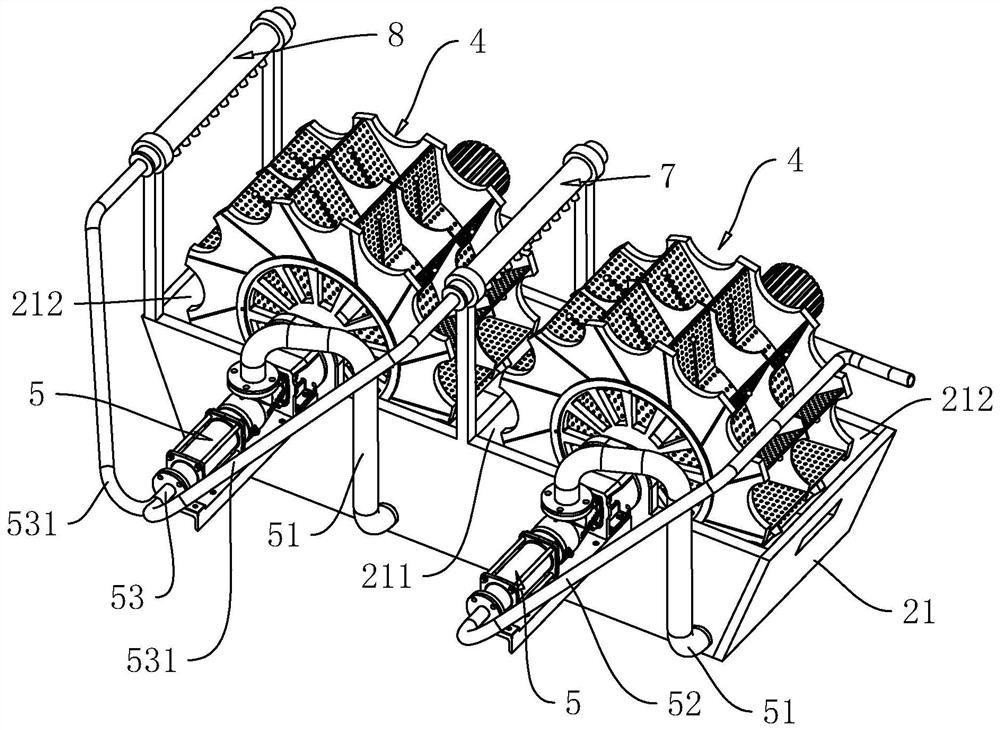

[0068] refer to figure 1 , The mud and sand washing treatment system for abandoned buildings includes a drum screen 1, a washing machine 2 and a dewatering screen 3 arranged in sequence. When working, the material is firstly screened by the drum screen 1, and the remaining large impurities are discharged after screening. The mud and sand falling during screening enter the washing machine 2, and are washed by the washing machine 2. After washing, the sand enters the dewatering screen 3 , through the screening of the dewatering screen 3, the last remaining is the qualified recycled sand, which can be discharged.

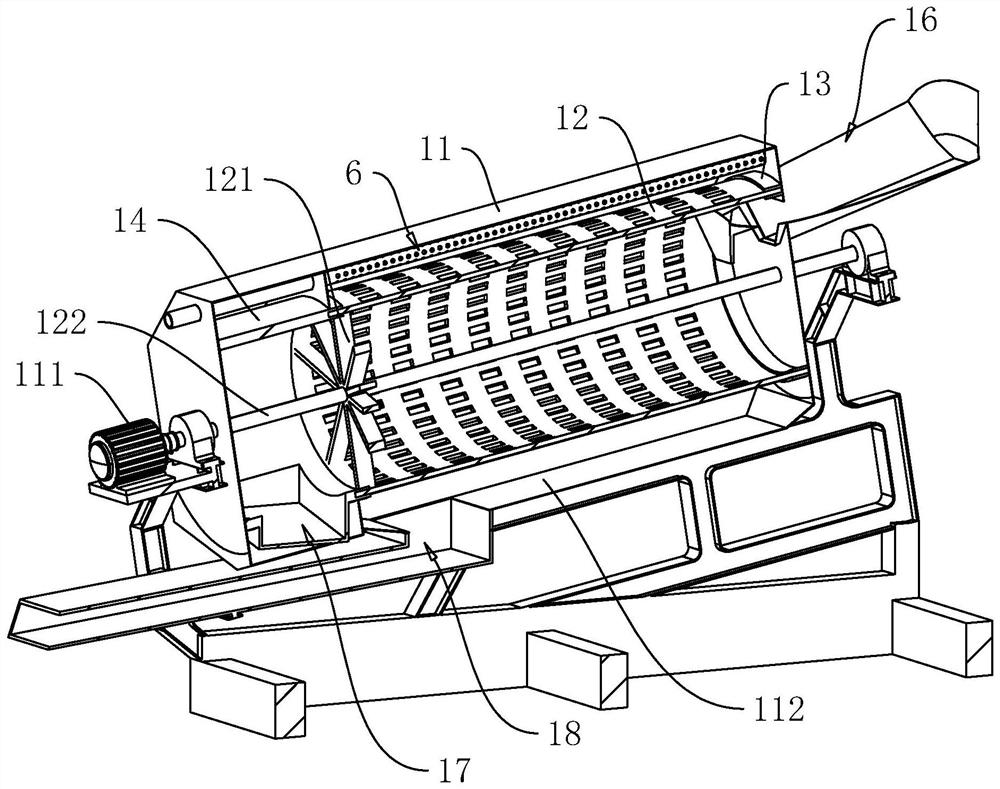

[0069] refer to figure 2 The trommel screen 1 includes a frame 11, and the frame 11 is provided with a sieve cylinder 12 with an axis direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com