Additive manufacturing method of integrated injector

An additive manufacturing and injector technology, which is applied in the field of metal additive manufacturing, can solve the problems of strict sealing effect requirements, high welding precision requirements, uncoordinated deformation, etc., and achieves reduction of processes, high reliability, and avoidance of uncoordinated deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

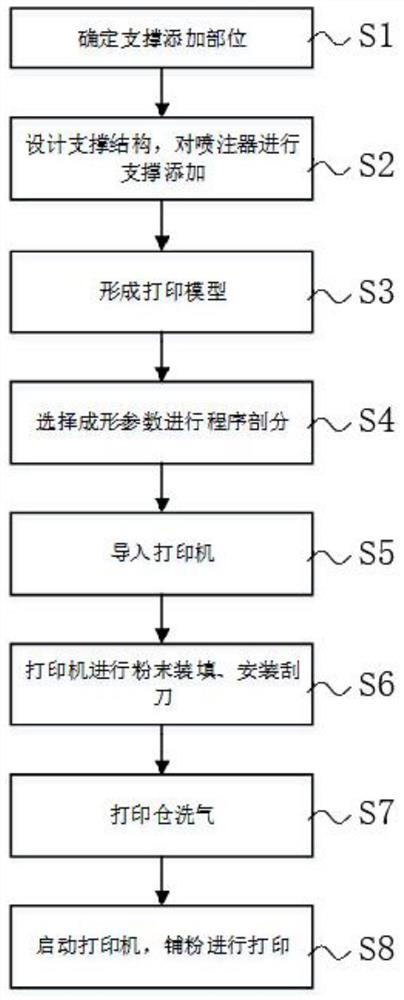

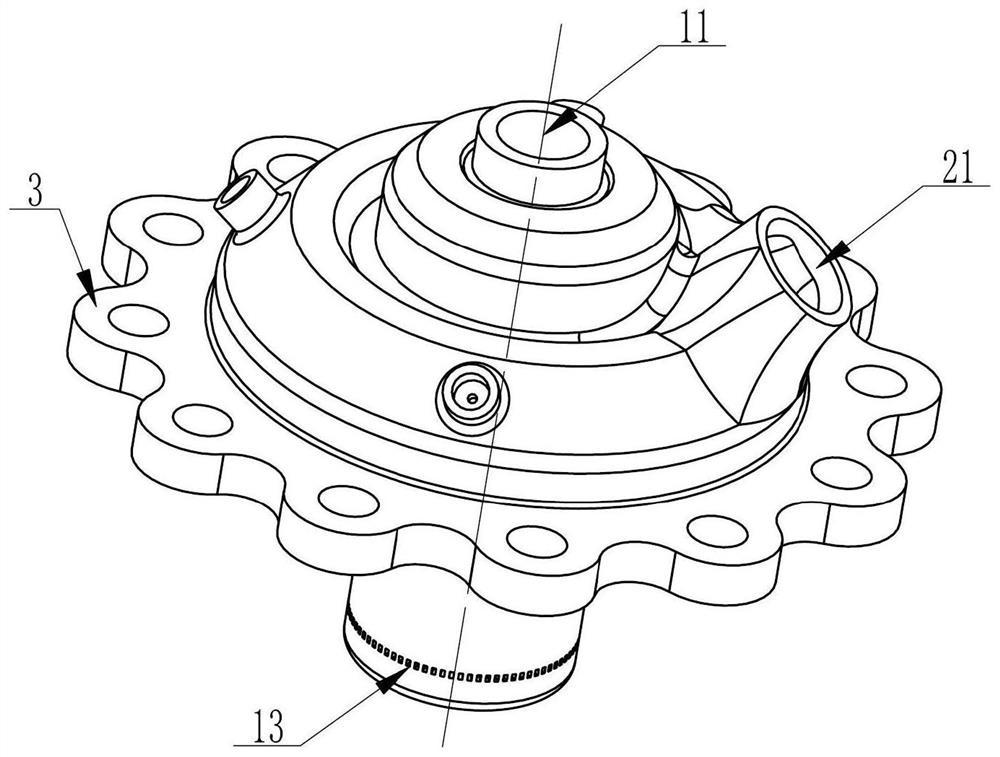

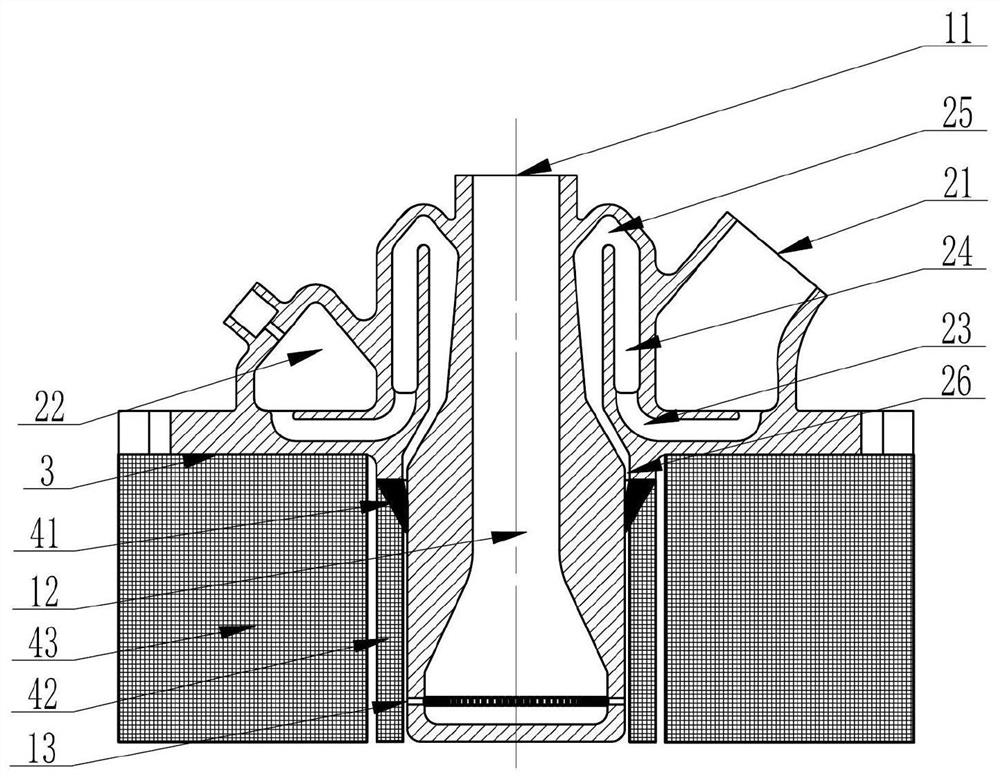

[0047] Figure 1-3 It is an embodiment of the present invention: an additive manufacturing method of an integrated injector, the additive manufacturing method is laser selective melting forming, and the forming method realization steps include:

[0048] S1. Determine the location where the support is added, make sure that the fuel inlet of the injector is placed upwards, and determine the lower end of the mounting flange and the location where the support is added;

[0049] S2. Design the support structure, add support to the injector, design solid support and block support structure, and add support to the integrated injector;

[0050] S3, forming a printing model, combining the three-dimensional model of the integrated injector and the designed support structure to form a printing model;

[0051] S4. Select the forming parameters for program subdivision, select the injector's solid support, block support, surface layer and solid forming parameters for program subdivision; ...

Embodiment 2

[0074] Figure 1-3 It is an embodiment of the present invention: an additive manufacturing method of an integrated injector, the additive manufacturing method is laser selective melting forming, and the forming method realization steps include:

[0075] S1. Determine the location where the support is added, make sure that the fuel inlet of the injector is placed upwards, and determine the lower end of the mounting flange and the location where the support is added;

[0076] S2. Design the support structure, add support to the injector, design solid support and block support structure, and add support to the integrated injector;

[0077] S3, forming a printing model, combining the three-dimensional model of the integrated injector and the designed support structure to form a printing model;

[0078] S4. Select the forming parameters for program subdivision, select the injector's solid support, block support, surface layer and solid forming parameters for program subdivision; ...

Embodiment 3

[0101] Figure 1-3 It is an embodiment of the present invention: an additive manufacturing method of an integrated injector, the additive manufacturing method is laser selective melting forming, and the forming method realization steps include:

[0102] S1. Determine the location where the support is added, make sure that the fuel inlet of the injector is placed upwards, and determine the lower end of the mounting flange and the location where the support is added;

[0103] S2. Design the support structure, add support to the injector, design solid support and block support structure, and add support to the integrated injector;

[0104] S3, forming a printing model, combining the three-dimensional model of the integrated injector and the designed support structure to form a printing model;

[0105] S4. Select the forming parameters for program subdivision, select the injector's solid support, block support, surface layer and solid forming parameters for program subdivision; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com