Angle grinding sheet and preparation method thereof

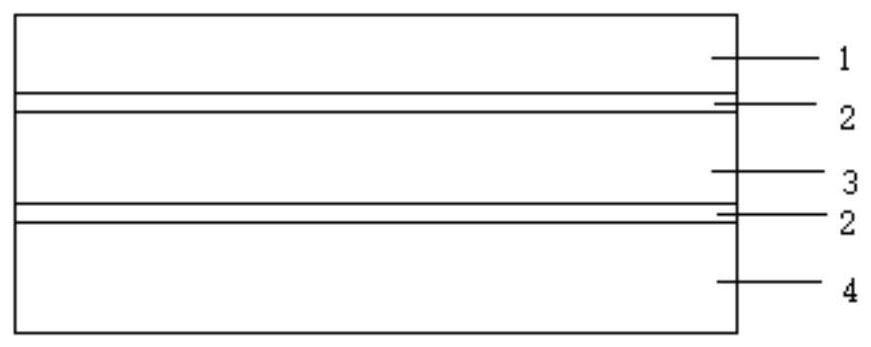

An angle grinding disc and rough grinding technology, used in grinding/polishing equipment, abrasives, grinding devices, etc., can solve problems such as easy to drop blocks, and achieve the effect of not easy to drop blocks, good balance, and uniform grinding wheel wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] S1. Weigh and mix the coarse material and the fine material according to the following mass percentages for subsequent use, then sieve the coarse material through a 14-mesh sieve, and sieve the fine material through a 40-mesh sieve;

[0040] Coarse material: 8% cryolite, 6% phenolic resin solution, 12% phenolic resin powder, 20% brown corundum with particle size F22, 30% brown corundum with particle size F24, 24% white corundum with particle size F30;

[0041] Fine material: 3% cryolite, 5% epoxy resin, 10% phenolic resin solution, 25% phenolic resin powder, 20% brown corundum with particle size F60, and 37% white corundum with particle size F60.

[0042] S2. Preheat the mold to 45°C, put the mixed fine material raw materials into the abrasive tool, and flatten it to obtain a fine material non-grinding surface layer; the thickness of the fine material non-grinding surface layer accounts for 1 / of the total thickness of the angle grinding disc 4.

[0043] S3. Put a laye...

Embodiment 2

[0049] S1. Weigh and mix the coarse material and the fine material according to the following mass percentages for subsequent use, then sieve the coarse material through a 18-mesh sieve, and sieve the fine material through a 60-mesh sieve;

[0050] Coarse material: 3% cryolite, 5% phenolic resin solution, 10% phenolic resin powder, 15% brown corundum with particle size F22, 40% brown corundum with particle size F24, 27% white corundum with particle size F30;

[0051] Fine material: 1% cryolite, 2% epoxy resin, 3% phenolic resin liquid, 10% phenolic resin powder, 21% white corundum with particle size F100, 63% brown corundum with particle size F100.

[0052] S2. Preheat the mold to 40°C, put the mixed fine material raw materials into the grinding tool, and flatten it to obtain a fine material non-grinding surface layer; the thickness of the fine material non-grinding surface layer accounts for 1 / of the total thickness of the angle grinding disc 6.

[0053] S3. Put a layer of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com