Zero field dysprosium single ion magnet and preparation method and application thereof

A single-ion, magnet technology, applied in organic chemistry methods, chemical instruments and methods, preparation of organic compounds, etc., can solve problems such as low yield, easy decomposition or weathering, instability, etc., to achieve safe, simple and reproducible processes. Good performance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

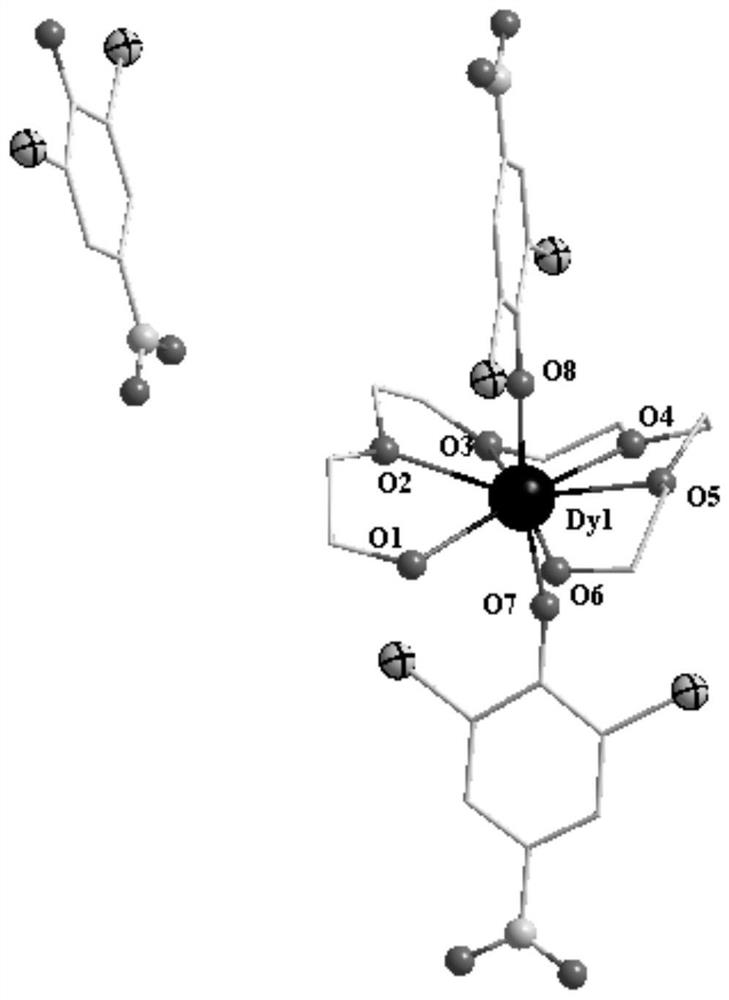

[0023] The preparation method of zero-field dysprosium single-ion magnet comprises: 2,6-dichloro-4-nitrophenol (HOPhCl 2 NO 2 ) (1mmol) was dissolved in 10mL tetrahydrofuran, NaH (1mmol) was added to it, and it was ultrasonicated for 10min until no bubbles were generated, and DyCl 3 (0.5mmol) was added therein, stirred for 12h, the solution was a yellow suspension, filtered to remove the precipitate, and the filtrate was spin-dried to obtain a yellow solid, which was then dissolved in 10mL of acetonitrile:methanol (3:1) mixed solvent, and Add pentaethylene glycol (EO5) (0.5mmol) dropwise, stir for 2h, and spin dry to obtain a yellow oil, which is dissolved in 5mL of dichloromethane, transferred to a test tube, and 15mL of n-hexane is slowly added to it, and left to stand for two-phase diffusion In 2 days, the dysprosium single ion magnet was obtained.

[0024] The yield of the dysprosium single-molecule magnet prepared in this example is 64.4%.

Embodiment 2

[0026] The preparation method of zero-field dysprosium single-ion magnet comprises: 2,6-dichloro-4-nitrophenol (HOPhCl 2 NO 2 ) (1.5mmol) was dissolved in 15mL tetrahydrofuran, NaH (1.5mmol) was added to it, and it was ultrasonicated for 10min until no bubbles were generated, and DyCl 3 (0.5mmol) was added therein, stirred for 12h, the solution was a yellow suspension, filtered to remove the precipitate, and the filtrate was spin-dried to obtain a yellow solid, which was dissolved in 15mL of acetonitrile:methanol (3:1) mixed solvent, and Add pentaethylene glycol (EO5) (0.7mmol) dropwise, stir for 2h, and spin dry to obtain a yellow oil, dissolve it in 7mL of dichloromethane, transfer it to a test tube, slowly add 20mL of n-hexane into it, let it stand for two-phase diffusion After 4 days, the dysprosium single ion magnet was obtained.

[0027] The yield of the dysprosium single-molecule magnet prepared in this example is 67.2%.

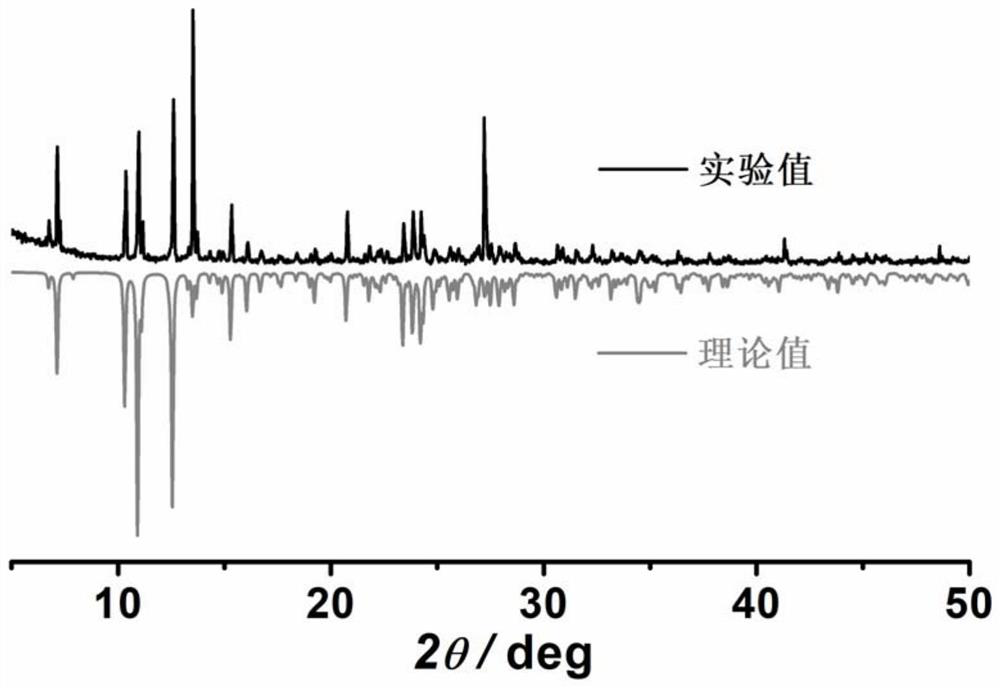

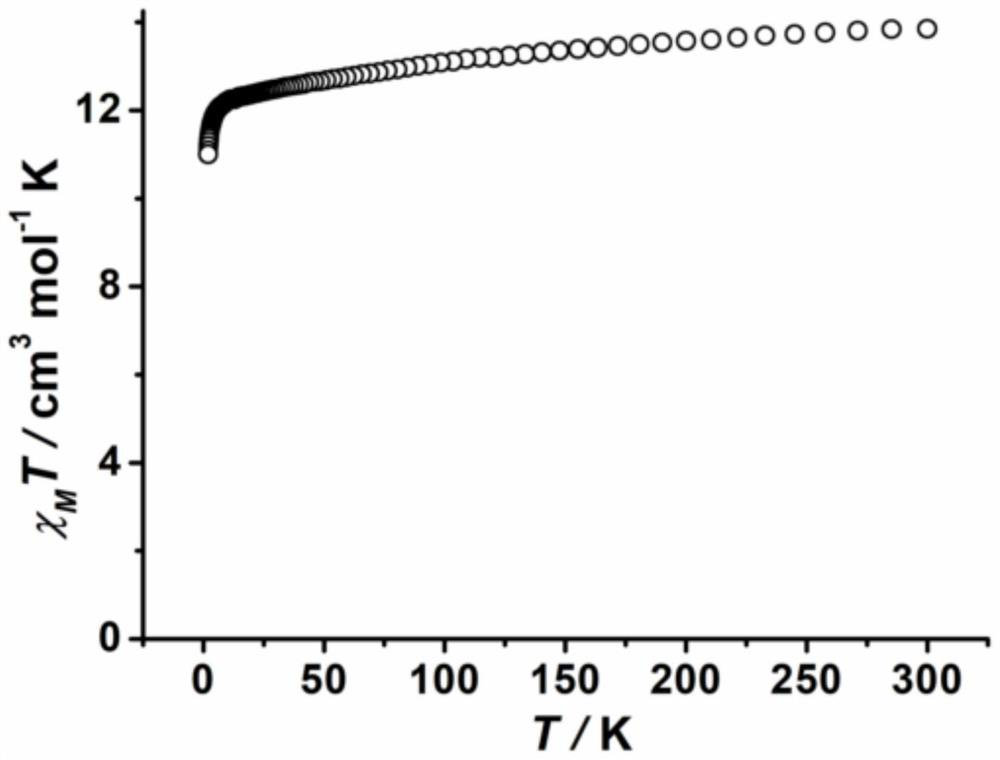

[0028] The dysprosium single-ion magnet prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com