Bubble water and preparation method thereof

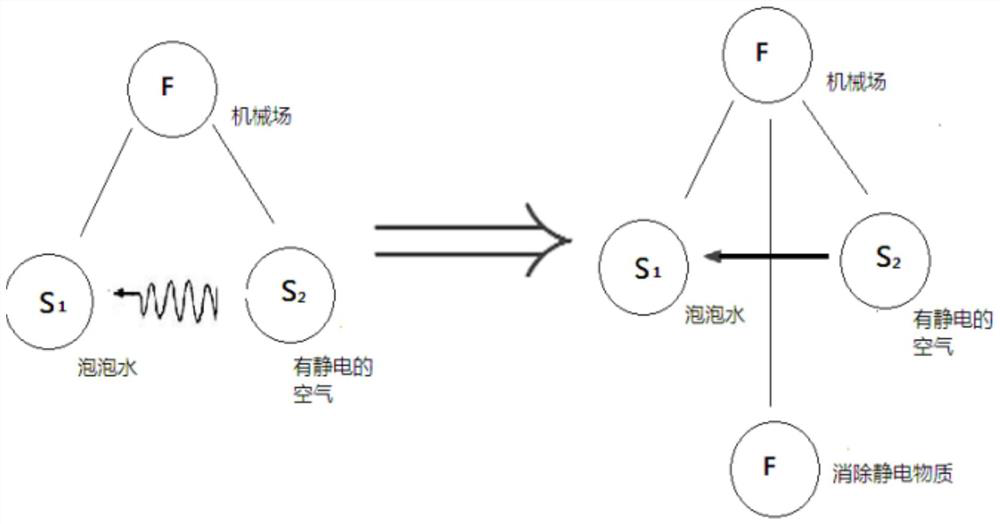

A technology of bubble water and foaming agent, which is applied in the field of bubble water and its preparation, can solve the problems of poor bubble blowing performance and human health hazards, so as to increase the number of bubbles, prolong the service life of the bubbles, and improve the production efficiency. membranous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Weigh 992.99g of hot water at 65°C and pour it into a glass reaction kettle with a stirring device, start the stirrer to stir rapidly, slowly add 0.5g of cationized hydroxyethyl cellulose with a viscosity of 20°C of 20°C to 10000mpa·s cationized hydroxyethyl cellulose, and adjust Slow mixer speed, continue to stir for 10 minutes, add CAB35 betaine (solid content is 35%) 5g, EDTA2Na 0.5g, phenoxyethanol preservative 0.5g, benzyl ammonium benzoate amide 0.01g, ethylparaben 0.5g, Continue stirring for 5 minutes, stop stirring and cool to obtain bubble water. Test the bubble water with a mouth-blowing bubble stick, and can continuously blow out a lot of bubbles with a diameter of about 2-5cm, which are colorful; but no bubbles can be emitted by the bubble machine, because the amount of effective components in this embodiment is less, Only suitable for mouth-blown bubble wands with low wind speed.

Embodiment 2

[0036] Weigh 957.99g of hot water at 65°C and pour it into a glass reaction kettle with a stirring device, start the stirrer to stir rapidly, slowly add 2% aqueous solution with a viscosity of 10000mpa·s at 20°C, and 3g of cationized hydroxyethyl cellulose, slow down Mixer speed, continue to stir for 10 minutes, add mixed alkyl glucoside (content is 40%) 30g, EDTA4Na 1g, phenoxyethanol preservative 5g, benzoic acid benzyl ammonium amide 0.01g, ethylparaben 3g, continue to stir for 5 minutes , stop stirring and cool to get bubble water. Test the bubble water with a mouth-blowing bubble stick, and it can blow out a lot of bubbles with a diameter of about 2-5cm continuously, and launch it with a bubble machine with a diameter of 2cm, and there are also a large number of bubbles with a diameter of about 2-10cm, which are colorful.

Embodiment 3

[0038] Weigh 941.99g of hot water at 65°C and pour it into a glass reaction kettle with a stirring device, start the stirrer to stir quickly, slowly add 2% aqueous solution with a viscosity of 100,000mpa·s at 20°C, 5g of cationized hydroxyethyl cellulose, and adjust slowly Mixer speed, continue to stir for 10 minutes, add powdery dodecyl betaine 20g, dodecyl imidazoline (content is 40%) 25g, EDTA4Na 1g, phenoxyethanol preservative 5g, benzyl ammonium benzoate amide 0.01g , ethylparaben 3g, continue stirring for 5 minutes, stop stirring and cool to obtain bubble water. With an electric bubble gun with a diameter of 10cm, it can continuously blow out many bubbles with a diameter of about 10-20cm, which is colorful. In this embodiment, the cationized hydroxyethyl cellulose has a large molecule, so larger bubbles can be blown out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com