Method for improving blade profile correcting and machining precision of integrally cast impeller of gas compressor

A technology of overall casting and machining accuracy, applied in the direction of climate sustainability, efficient propulsion technology, sustainable transportation, etc., can solve the problems of cumulative error, the inability to accurately calibrate a single blade shape, and the inability to quantify the comparison and calibration, etc. Achieve the effect of improving calibration and machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

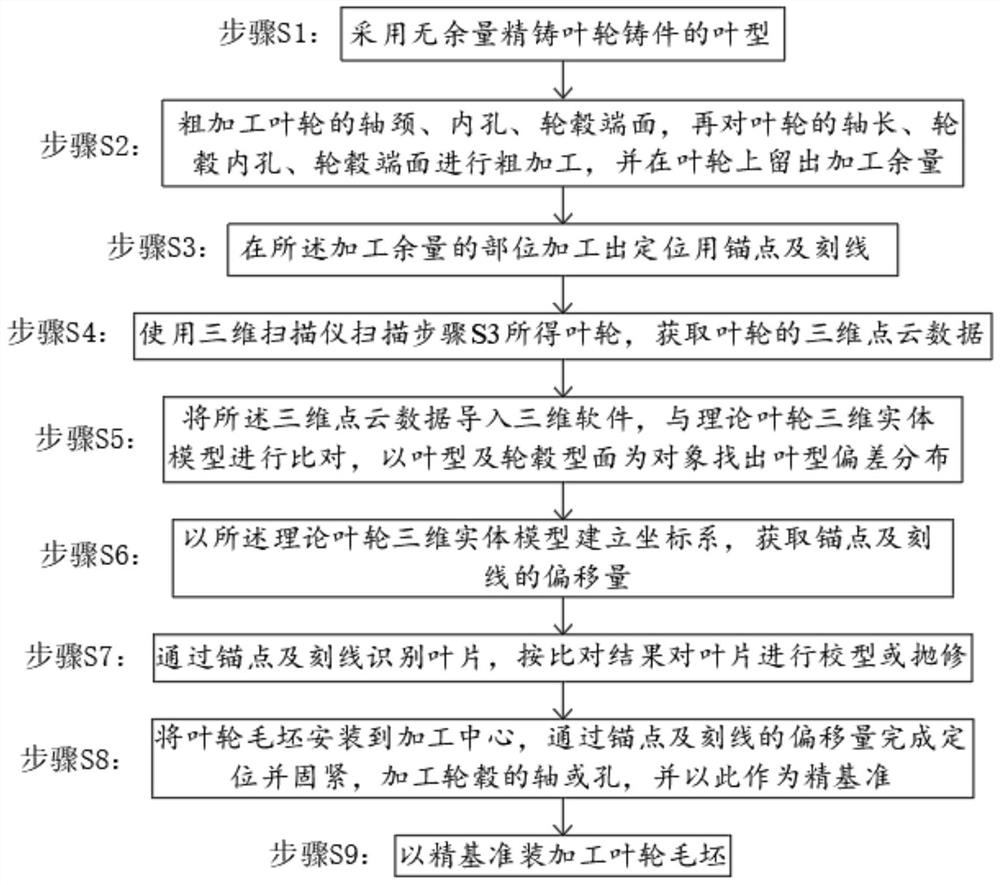

[0039] Such as figure 1 As shown, the present invention discloses a method for improving the type correction and machining accuracy of integrally cast impeller blades of a compressor, including:

[0040] Step S1: Adopting the airfoil shape of precision cast impeller castings without margin to ensure that the airfoil shape meets the requirements of the blade blank;

[0041] Step S2: According to the conventional method of aligning the impeller according to the template, roughly machine the journal, inner hole, and hub end face of the impeller as a rough reference, and then roughly machine the axial length of the impeller, the inner hole of the hub, and the end face of the hub, and reserve them on the impeller. Out of the corresponding processing allowance;

[0042] Step S3: Machining anchor points and scoring lines for positioning at the part of the machining allowance;

[0043] Step S4: Use a high-precision 3D scanner to scan the impeller obtained in step S3 to obtain 3D poi...

Embodiment 2

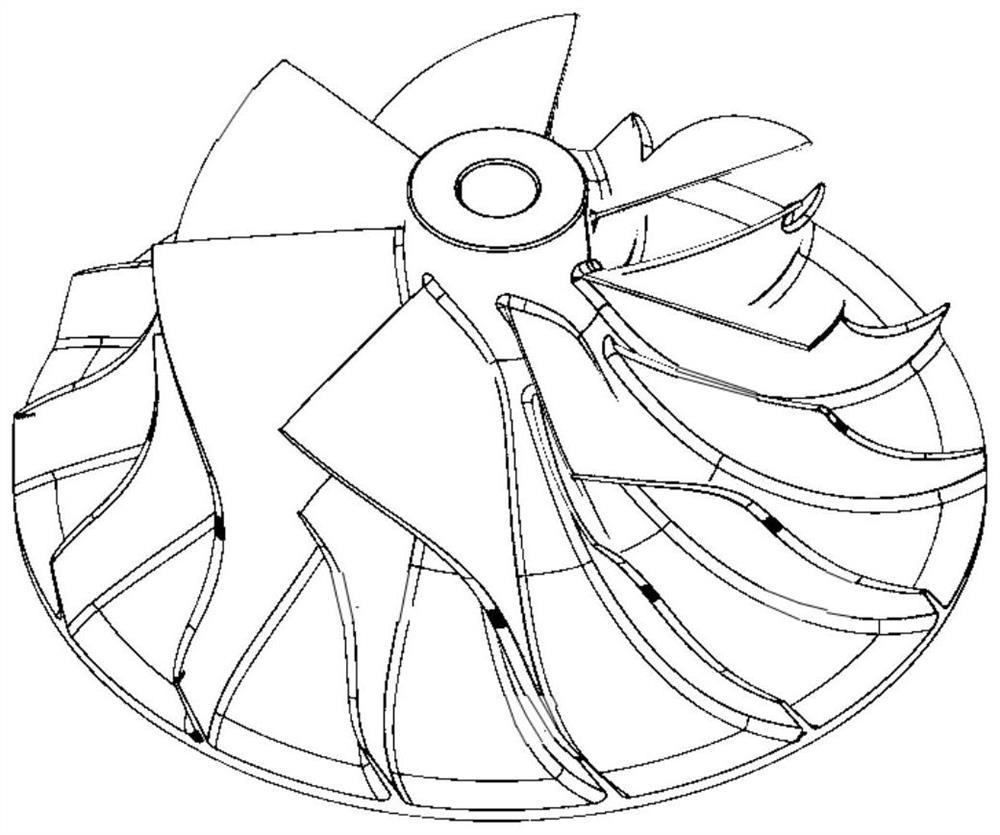

[0062] Such as Figure 2 to Figure 3 As shown, a specific embodiment,

[0063] The compressor of a micro engine is an integral impeller, the design requires that the error of the profile is less than 0.05mm, and it adopts precision investment casting.

[0064] Process the impeller according to the processing method in Example 1,

[0065] Preliminary machining is performed on the impeller length, inner hole of the hub, end face of the hub and other dimensions, and the corresponding allowance is reserved.

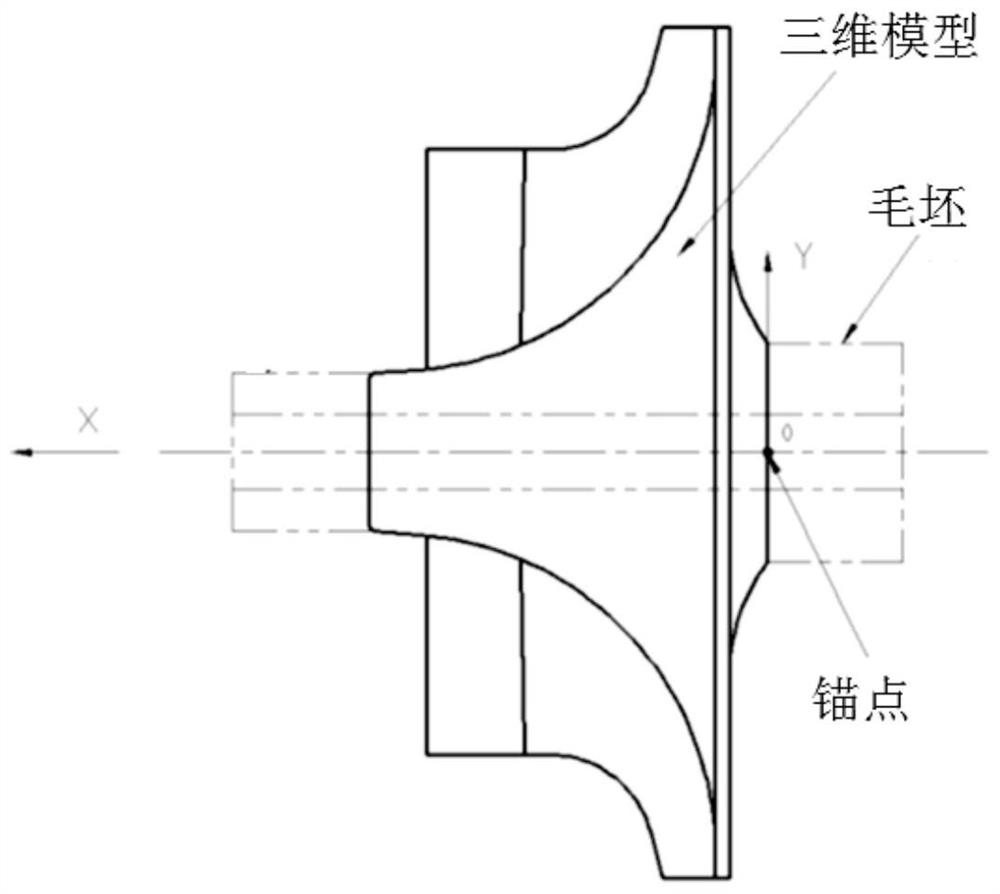

[0066] A hole with a depth of about 1mm and a diameter of about 2mm is machined on the end surface of the inlet side of the pre-processed hub (after the completion of the blade shape calibration and polishing, the hole is finally processed and removed), and the hole is used as a positioning anchor point; the origin of the coordinate system O is The intersection point of the inlet side end surface of the hub and the axis of the impeller, the X-axis is the axis of the impelle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com