Low-viscosity and high-thixotropy composition

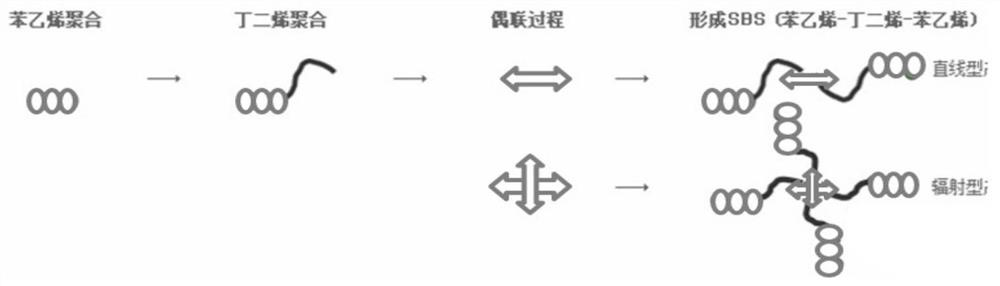

A composition, high thixotropic technology, applied in the direction of polymer adhesive additives, adhesive additives, coatings, etc., can solve problems such as affecting product process usability, disappearing thixotropy, and increasing system viscosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

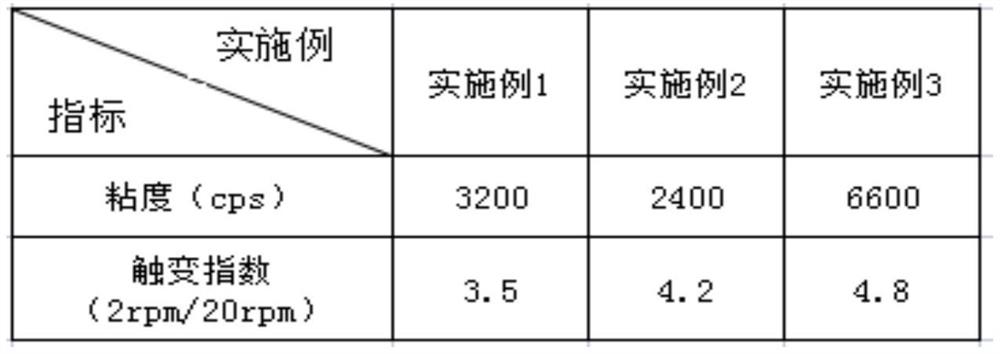

Embodiment 1

[0016] Add 30g of methyl methacrylate, 10g of hydroxyethyl methacrylate, 5g of 2-methyl-2-acrylic acid-2-hydroxyethyl phosphate into the reaction stirred tank, stir for 0.5h, and control the temperature at 40-50 ℃, then add ABS Blendex 338 12g, SBS D1116 8g and stir at high speed for 1 hour, the temperature is controlled at 40-50 ℃, after the materials are evenly stirred, vacuumize for 5 minutes at last, and then discharge to obtain a low-viscosity high-thixotropic composition.

Embodiment 2

[0018] Add 35g of tetrahydrofuryl methacrylate, 10g of hydroxyethyl methacrylate, and 5g of hydroxypropyl methacrylate into the reaction stirred tank, stir for 0.5h, and control the temperature at 40-50°C, then add MBS M-52110g, SBS DZ -3003 10g high-speed stirring for 1 hour, the temperature is controlled at 40-50 ℃, after the material is evenly stirred, vacuumize for 5 minutes at last, and then discharge the material to obtain a low-viscosity high-thixotropic composition.

Embodiment 3

[0020] Add 18g of methyl methacrylate, 20g of hydroxyethyl methacrylate, and 15g of tetrahydrofuryl methacrylate into the reaction stirred tank, stir for 0.5h, and control the temperature at 40-50°C, then add ABS WD-13212g, MBS M- 711 8g and SBSLCY-3411 14g were stirred at high speed for 1 hour, and the temperature was controlled at 40-50°C. After the materials were evenly stirred, they were finally vacuumed for 5 minutes, and then discharged to obtain a low-viscosity, high-thixotropic composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thixotropic index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com