Jacking installation method for large-span single-layer aluminum alloy circular reticulated shell

An installation method and aluminum alloy technology, which are applied in construction, building structure, construction material processing, etc., can solve the problems of high construction cost, large amount of high-altitude work, and long construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

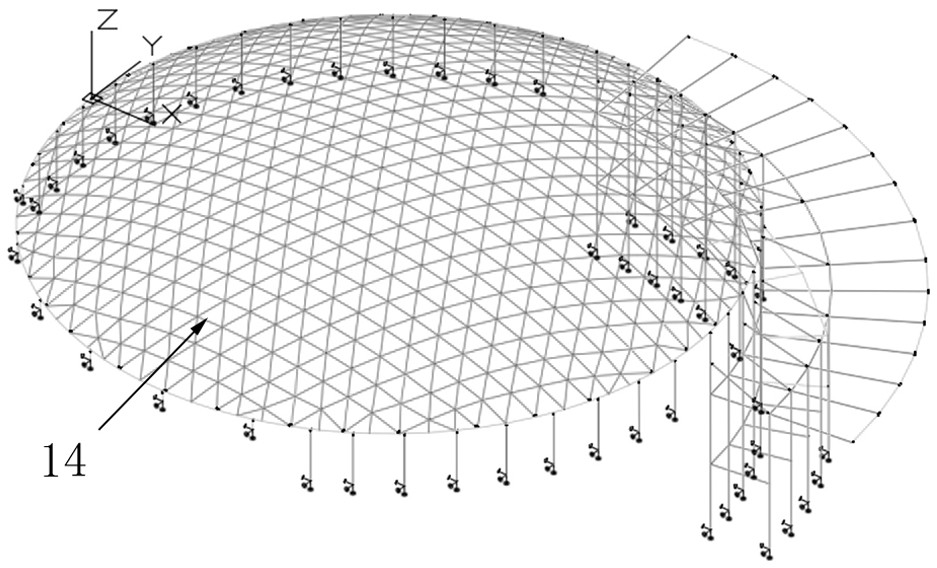

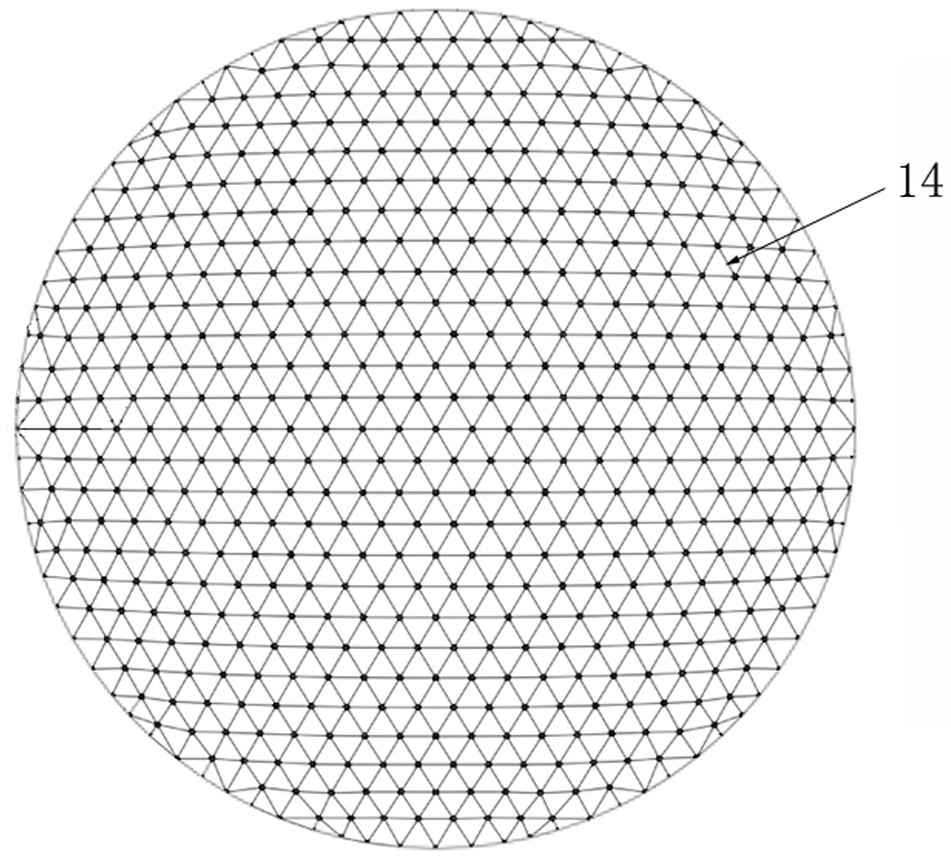

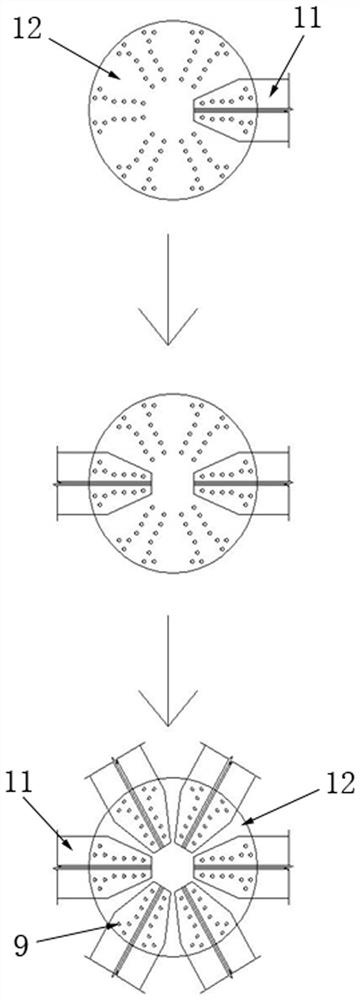

[0057] A construction project is to build a large-span single-layer aluminum alloy circular reticulated shell structure roof, such as figure 1 with figure 2 As shown, the reticulated shell 14 has a diameter of 60m and a height of 9m, and is supported at multiple points around the steel beam and concrete beam top. The reticulated shell is a single-layer aluminum alloy plate node triangular grid, the grid size is about 2.5m*2.5m*2.5m, the rod 11 is made of 6061-T6 aluminum alloy profile, and the cross-section is H300*150*8*10; The lower node plates 10 and 12 are made of 6061-T6 aluminum alloy plate with a thickness of 12 mm; the nodes are connected by 304 stainless steel bolts 9 . The reticulated shell 14 has 1190 node disks, 1698 rods and 86178 stainless steel bolts.

[0058] The reticulated shell 14 is located in the center of the circular concrete frame building. The diameter of the building is 100m, and the width of the outer frame is 20m. The frame structure restricts th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com