Control device based on PLC computer system

A computer system and control device technology, applied in the field of PLC control, can solve the problems of low boiler combustion efficiency, low energy utilization rate, slow stability adjustment, etc., and achieve the effects of improving work efficiency, uniform spraying, and uniform combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

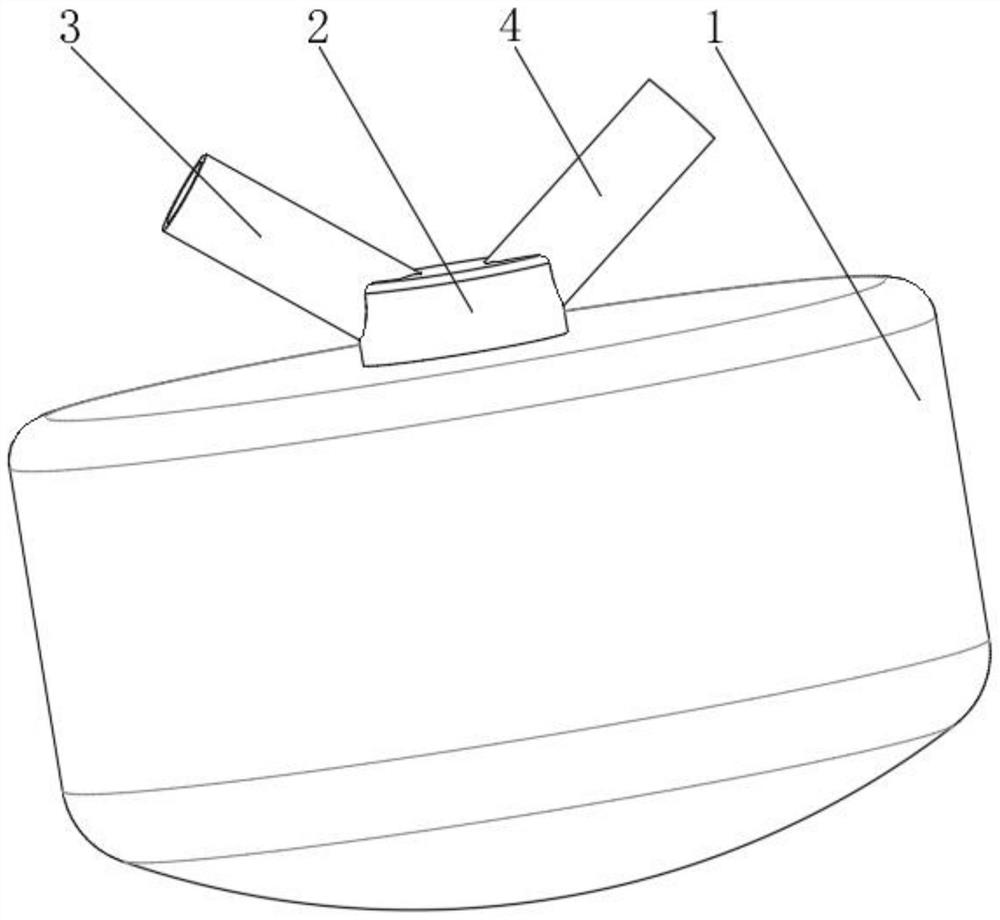

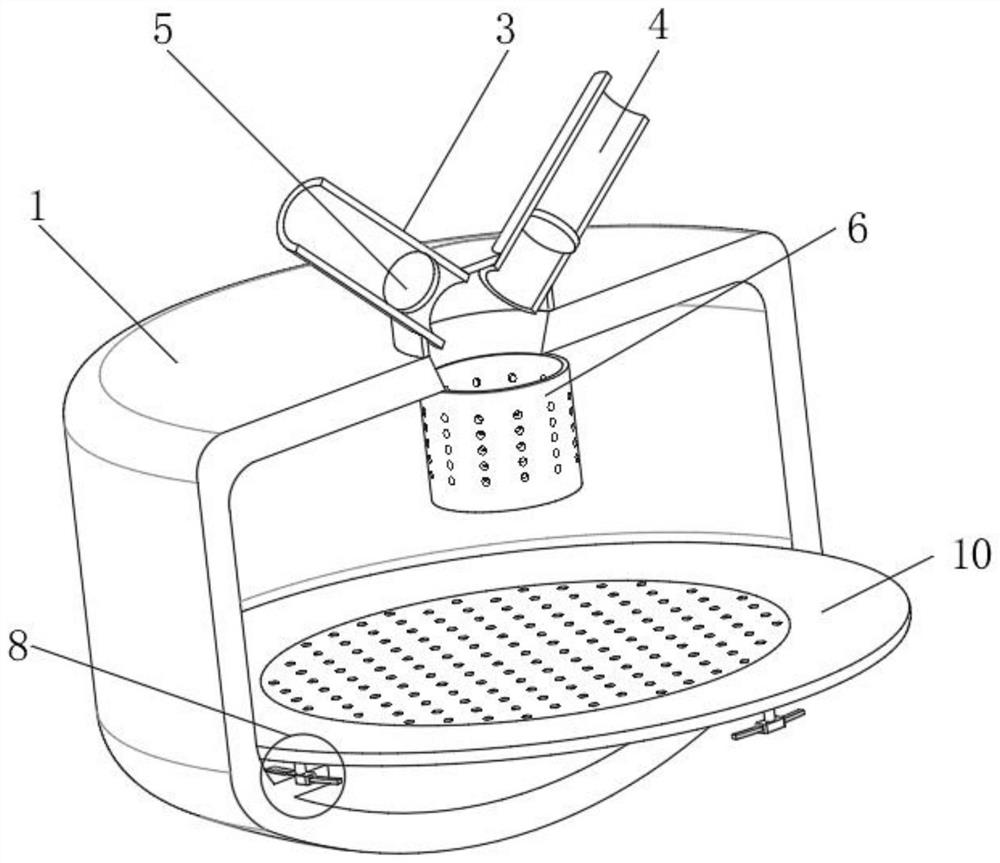

[0046] see Figure 1-3 , a control device based on a PLC computer system, comprising a furnace body 1, the top of the furnace body 1 is fixedly connected to a connecting platform 2, the top of the connecting platform 2 is interspersed with a powder material tube 3 and a block material tube 4, and the powder material tube 3 and the block material tube are interspersed. Rotate and connect the partition plate 5 in the material pipe 4;

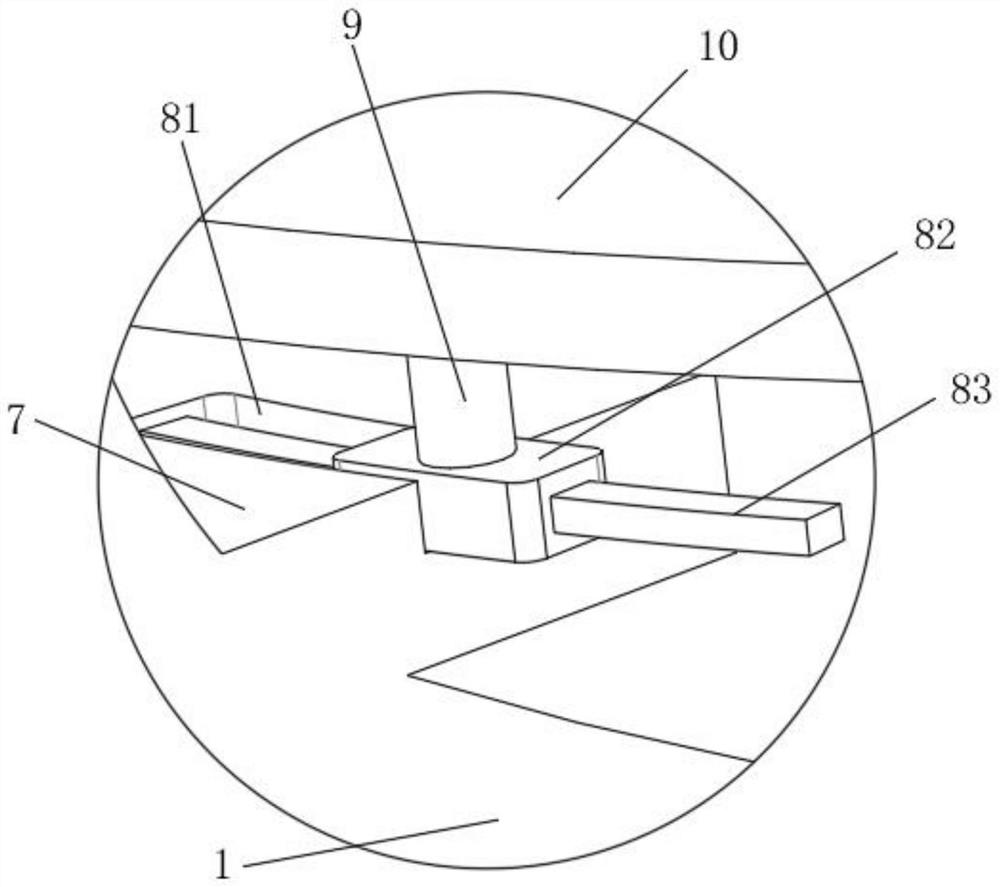

[0047] The inner wall of the furnace body 1 is fixedly connected to the base plate 7, and the top of the base plate 7 is provided with a vibrating mechanism 8 to prevent coal ash from accumulating;

[0048] A weighing device 9 is installed on the top of the vibration mechanism 8, and the top of the weighing device 9 is fixedly connected with a supporting plate 10.

[0049] The connection table 2 communicates with the discharge mechanism 6, and the inner wall of the powder material pipe 3 is provided with a fan interface, which is located on the l...

Embodiment 2

[0054] see Figure 1-6 , a control device based on a PLC computer system, comprising a furnace body 1, the top of the furnace body 1 is fixedly connected to a connection platform 2, and the top of the connection platform 2 is interspersed with a powder material tube 3 and a block material tube 4, and the powder material tube 3 and the block material tube Rotate and connect the partition plate 5 in the material pipe 4;

[0055] The inner top wall of the furnace body 1 is fixedly connected to the discharge mechanism 6 that controls the discharge method of powder and block materials;

[0056] The inner wall of the furnace body 1 is fixedly connected to the base plate 7, and the top of the base plate 7 is provided with a vibrating mechanism 8 to prevent coal ash from accumulating;

[0057] A weighing device 9 is installed on the top of the vibration mechanism 8, and the top of the weighing device 9 is fixedly connected with a supporting plate 10.

[0058] The connection table 2 ...

Embodiment 3

[0068] see Figure 7-8 , a method for using a control device based on a PLC computer system, the steps comprising:

[0069] S1. Select or write the required PLC program according to the usage, and input it into the PLC control system, turn on the equipment, start the PLC control, and control the operation of the equipment according to the PLC system settings;

[0070] S2. The system controls the material control device to throw fuel to the powder supply device and the lump supply device. The lump supply device releases the lump first, the igniter is ignited, and the powder supply device throws powder to support combustion;

[0071] S3. The equipment operates according to the system settings. When the fuel is burned, the oscillating device controls the incineration platform to shake, so that the coal ash falls;

[0072] S4. The temperature measurement module detects the temperature in the furnace. When the temperature is lower than the set temperature, enter step S8. When the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com