Magnetic thermal reactor device

A reactor, magnetocaloric technology, applied in chemical instruments and methods, chemical/physical/physical-chemical processes, chemical/physical/physical-chemical processes using energy, etc. Meet environmental protection requirements, slow heating speed and other problems, to achieve the effect of meeting large-scale industrial production, high energy efficiency, and rapid temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

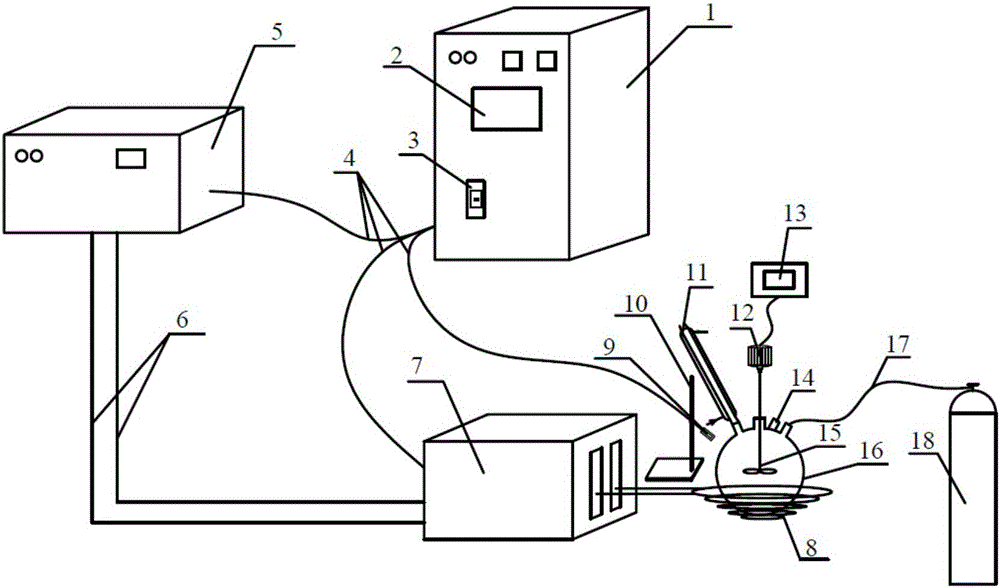

[0016] The magnetocaloric reactor device of the present invention that utilizes the magnetocaloric effect to heat the reaction is mainly composed of: a magnetocaloric power supply 1, a cooling system 5, a magnetocaloric transformer 7, a magnetocaloric coil 8 and a reactor 16. Among them, the magnetocaloric power supply 1 has a first control panel 2 and a power switch 3; the reactor 16 includes an infrared temperature measuring device 9, a condensation device 11, a material inlet 14, a stirring device 15, and an inert gas tank 18. The reactor 16 has four openings, of which the left opening is connected to the condensing device 11, the middle opening is connected to the stirring device 15, the right opening is connected to the air duct 17, and the side front opening is the material inlet 14. The cooling system 5 and the magnetocaloric transformer 7 are connected to the magnetocaloric power supply through a power line 4, the cooling system 5 and the magnetocaloric transformer 7 are...

Embodiment 2

[0020] The device is as described in Example 1. Take 3.8437g of anhydrous citric acid and 2.3833g of L-threonine, add 0.6339g (mass fraction 10%) of ferroferric oxide with a particle size of 20nm, stir and mix evenly, turn on the inert gas Switch and let in nitrogen gas. Turn on the magnetocaloric power switch, set the constant power program operation mode, set the power range to 12KW, and run time to 100 seconds. Press the reaction switch and the reaction will proceed. After the reaction is over, the taken-out solid is dissolved in water, and the magnetic medium is sucked out with a magnet, and the supernatant is the synthesized fluorescent carbon nanoparticle solution. Compared with other preparations of carbon nanoparticles, this method has the advantages that the heating speed is fast, and fluorescent nanomaterials can be synthesized in 100 seconds; we have obtained 4.5333g carbon dot solid powder, which can be used to prepare fluorescent materials on a large scale; The y...

Embodiment 3

[0022] The device is as described in Example 1. Hydroxypropyl acrylate (HPA), vinyl pyrrolidone (NVP), methylene bisacrylamide (MBAA), redox agent combination ammonium persulfate (APS) is miscible in glycerin, Stir uniformly in the reactor, and then add tetramethylethylenediamine (TMEDA). The relationship between the components is: HPA / NVP=3:1wt / wt(3g:1g), glycerin 6g, APS=0.4wt%(0.04g), [APS] / [TMEDA]=1:4mol / mol, MBAA =0.01wt% (0.001g). Then, 0.2 g (mass fraction 20%) of 50nm ferroferric oxide was added to the reactor, and the mixture was stirred and mixed uniformly. Turn on the magnetocaloric power switch, set the constant power operation mode, set the set power to 14KW, press the switch, about 30 seconds can provide enough energy to excite the magnetic particles to vibrate to generate heat, thereby preparing the hydrogel material. The use of magnetocaloric effect to initiate front-end polymerization is a new front-end polymerization method; at the same time, the prepared hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com