Preparation method of stuffed fish tofu capable of being stored at normal temperature

A technology of stuffed fish and fish tofu, which is applied in food coating, food science, and food ingredients as taste improvers, etc. It can solve the problems of stuffed fish tofu, such as sticky taste, affecting eating experience, and complicated production. Achieve the effect of improving the overall taste, improving elasticity and increasing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

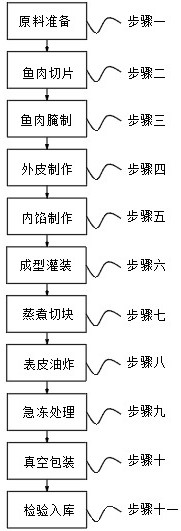

[0032] A method for preparing heart-wrapped fish tofu that can be stored at room temperature, comprising the following steps: step 1, raw material preparation; step 2, fish meat slices; step 3, fish meat soaking; step 4, outer skin making; step 5, inner filling making; Step 6, forming and filling; Step 7, steaming and cutting into pieces; Step 8, skin frying; Step 9, quick freezing treatment; Step 10, vacuum packaging; Step 11, inspection and storage;

[0033] Wherein in above-mentioned step one, prepare raw material according to weight component: 70 parts of fresh fish, 8 parts of high-gluten starch, 50 parts of ice water, 1.5 parts of salt, 0.3 part of cooking wine, 0.25 parts of pepper, 0.3 parts of 1 part of chicken essence, 40 parts of chicken, 20 parts of lean pork, 1 part of minced garlic, 5 parts of sesame oil, 1 part of lard and 1 part of cornstarch;

[0034] Wherein in the above-mentioned step 2, cut 70 parts of fresh fish meat prepared in the step 1 into slices of u...

Embodiment 2

[0045] A method for preparing heart-wrapped fish tofu that can be stored at room temperature, comprising the following steps: step 1, raw material preparation; step 2, fish meat slices; step 3, fish meat soaking; step 4, outer skin making; step 5, inner filling making; Step 6, forming and filling; Step 7, steaming and cutting into pieces; Step 8, skin frying; Step 9, quick freezing treatment; Step 10, vacuum packaging; Step 11, inspection and storage;

[0046] Wherein in above-mentioned step one, prepare raw material according to weight component: 90 parts of fresh fish, 10 parts of high-gluten starch, 55 parts of ice water, 2 parts of salt, 0.5 part of cooking wine, 0.45 part of pepper, 0.5 50 parts of chicken essence, 50 parts of chicken, 30 parts of lean pork, 2 parts of minced garlic, 15 parts of sesame oil, 5 parts of lard and 5 parts of cornstarch;

[0047] Wherein in the above-mentioned step two, 90 parts of fresh fish prepared in the step one are cut into slices of uni...

Embodiment 3

[0058] A method for preparing heart-wrapped fish tofu that can be stored at room temperature, comprising the following steps: step 1, raw material preparation; step 2, fish meat slices; step 3, fish meat soaking; step 4, outer skin making; step 5, inner filling making; Step 6, forming and filling; Step 7, steaming and cutting into pieces; Step 8, skin frying; Step 9, quick freezing treatment; Step 10, vacuum packaging; Step 11, inspection and storage;

[0059] Wherein in above-mentioned step one, prepare raw material according to weight component: 80 parts of fresh fish, 9 parts of high-gluten starch, 45 parts of ice water, 1.8 parts of salt, 0.4 part of cooking wine, 0.3 part of pepper, 0.4 45 parts of chicken essence, 45 parts of chicken, 25 parts of lean pork, 1.5 parts of minced garlic, 10 parts of sesame oil, 2.5 parts of lard and 2.5 parts of cornstarch;

[0060] Wherein in the above-mentioned step 2, cut 80 parts of fresh fish prepared in the step 1 into evenly sized, m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com