Clearing moistening film adhesive tape as well as preparation method and application thereof

A technology of cleansing and stripping, applied in the field of cleansing film strips, can solve the problems of cleansing mold strips with strong odor, strong odor, and secondary pollution, and achieve high film cleaning efficiency, cost reduction, and low odor effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of the clear and moisturizing film adhesive strip of the present invention comprises the following steps:

[0043] 1) masticating the uncrosslinked rubber;

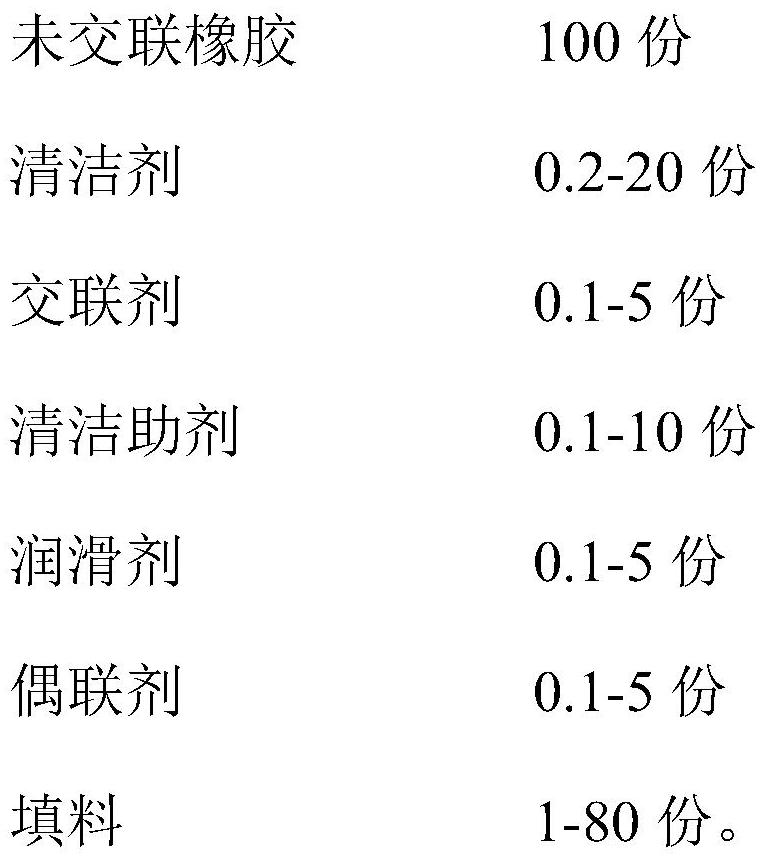

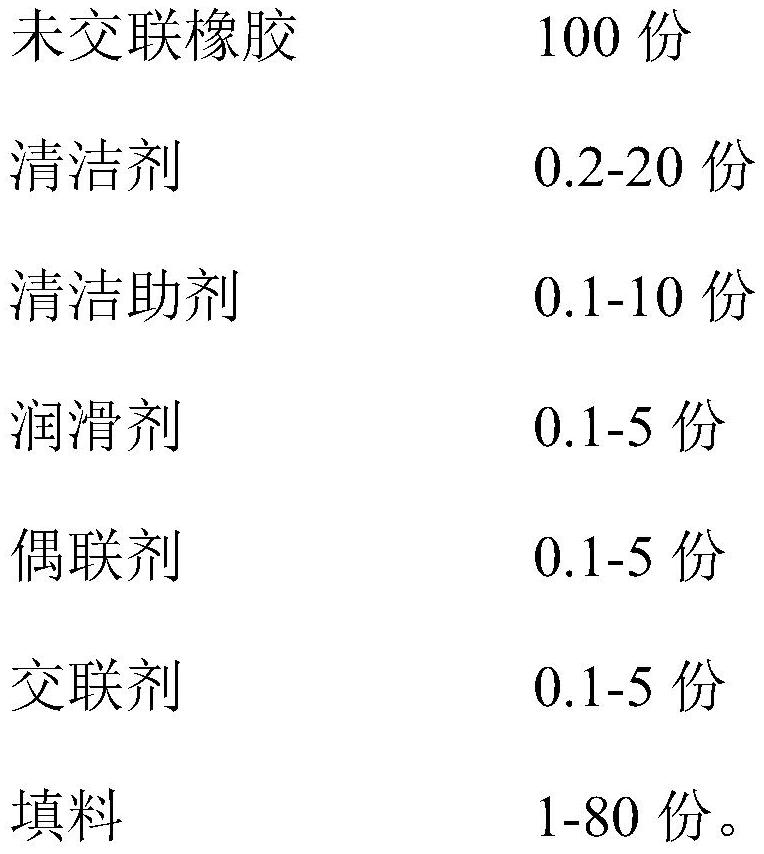

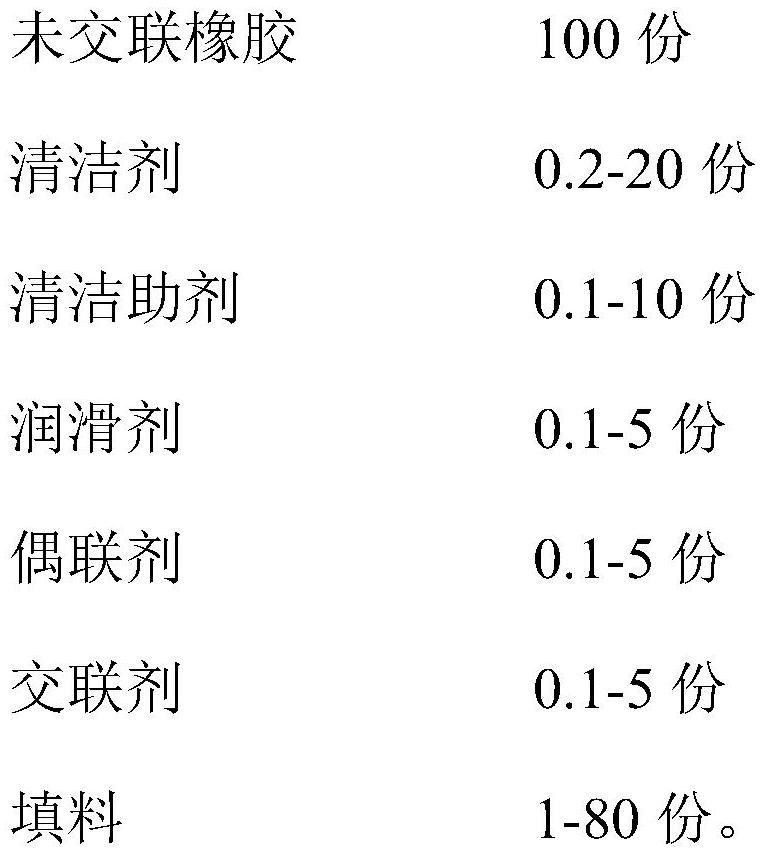

[0044] 2) Mix fillers, detergents, cleaning aids, lubricants, and coupling agents according to the proportion, then banbury, and add cross-linking agent to continue banbury;

[0045] 3) Mix the materials in step 1) and step 2), knead them, and cut them to obtain the moisturizing film strips.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com