Preparation method of transition metal chalcogenide crystal

A technology of chalcogenides and transition metals, which is applied in the field of materials, can solve the problems of limiting the final size of crystals and the inability to prepare large-sized and high-quality transition metal chalcogenide crystals, and achieve high-quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

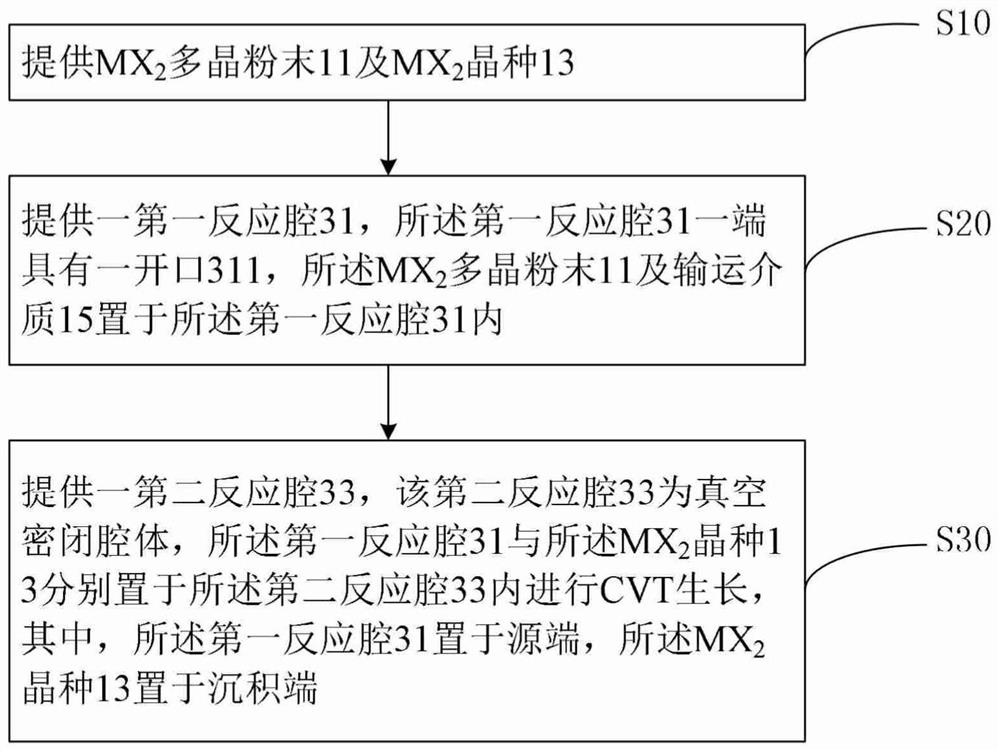

[0025] The preparation method comprises the following steps:

[0026] Step S10, providing MX 2 Polycrystalline powder 11 and MX 2 Seed 13;

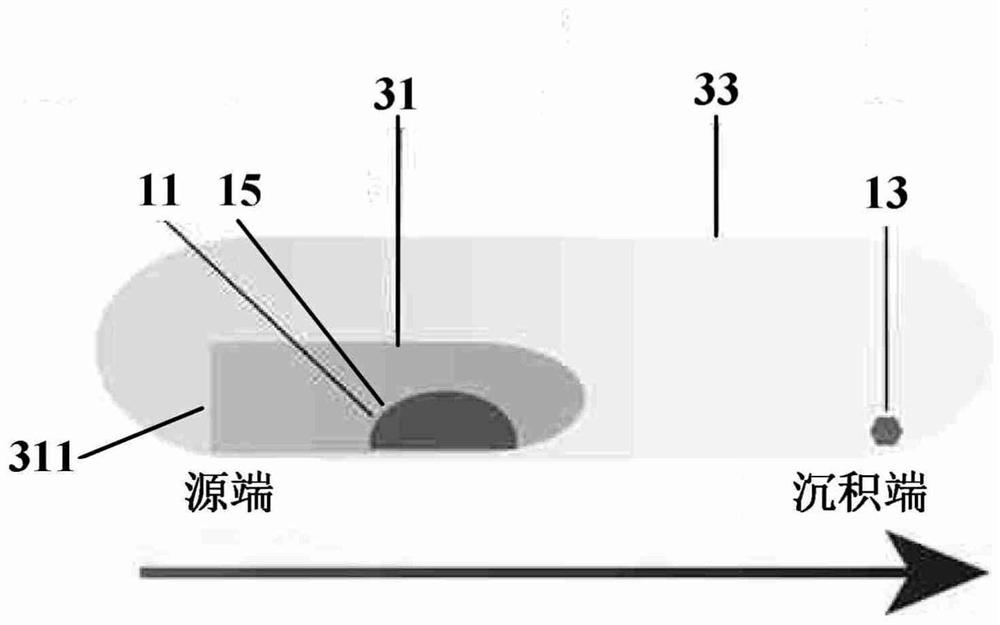

[0027] Step S20, providing a first reaction chamber 31, one end of the first reaction chamber 31 has an opening 311, the MX 2 The polycrystalline powder 11 and the transport medium 15 are placed in the first reaction chamber 31; and

[0028] Step S30, providing a second reaction chamber 33, the second reaction chamber 33 is a vacuum-tight chamber, the first reaction chamber 31 and the MX 2 The seeds 13 are respectively placed in the second reaction chamber 33 for CVT growth, wherein the first reaction chamber 31 is placed at the source end, and the MX 2 A seed crystal 13 is placed at the deposition end.

[0029] In step S10, the polycrystalline MX 2 Powder 11 is a hundred-micron powder with no obvious luster, and twins, grain boundaries or rough surfaces are likely to exist.

[0030] The polycrystalline MX 2 Powder 11 can be obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com