Light long-distance cross-sea intelligent permanent railway and highway floating bridge with low manufacturing cost and short construction period

A pontoon pier and buoyancy technology, which is applied in the field of light-duty long-distance cross-sea intelligent permanent railway and highway pontoons with low cost and short construction period, can solve the problems of reducing investment, shortening construction period, and small impact on the ecological environment of the strait.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

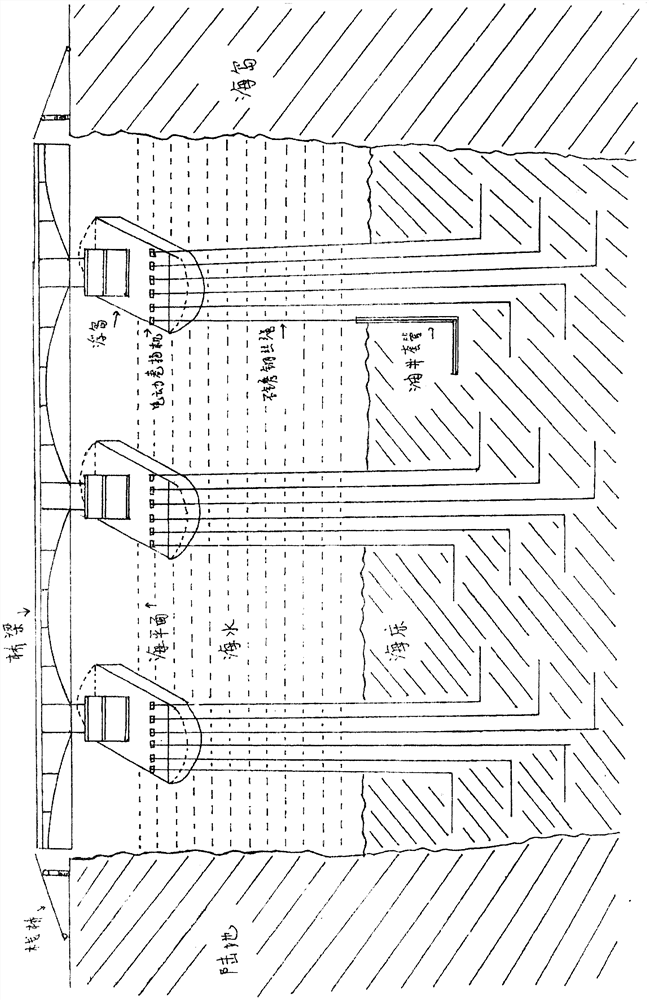

[0018] Use the buoyancy of seawater to build floating islands. Each floating island is held firmly by stainless steel wire ropes rooted on the seabed. The floating islands can be made of cheap corrosion-resistant materials, and bridges are built on the floating islands. Attached picture

[0019] 1. Tie the seabed rooting stainless steel wire rope of the floating island

[0020] (1) N pontoon piers, namely floating islands, are uniformly pre-designed and arranged along the width direction of the strait.

[0021] (2) Using a relatively low-cost mobile jack-up offshore oil drilling platform, drill 6 special wells DN140 with uniform and symmetrical distances on the seabed below the left and right sides of each floating island (the depth of the wells is based on The depth of seawater and the thickness of seabed silt, for example, the Qiongzhou Strait is about 100 meters deep), and the well spacing is determined according to the size of the floating island. The cost of drilling ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com