Artificial leather effluent treating process

A wastewater treatment and artificial leather technology, which is applied in animal processing wastewater treatment, degassed water/sewage treatment, neutralized water/sewage treatment, etc., can solve problems such as difficult to meet standards, difficult to meet national discharge standards, and difficult process treatment. The effect of good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

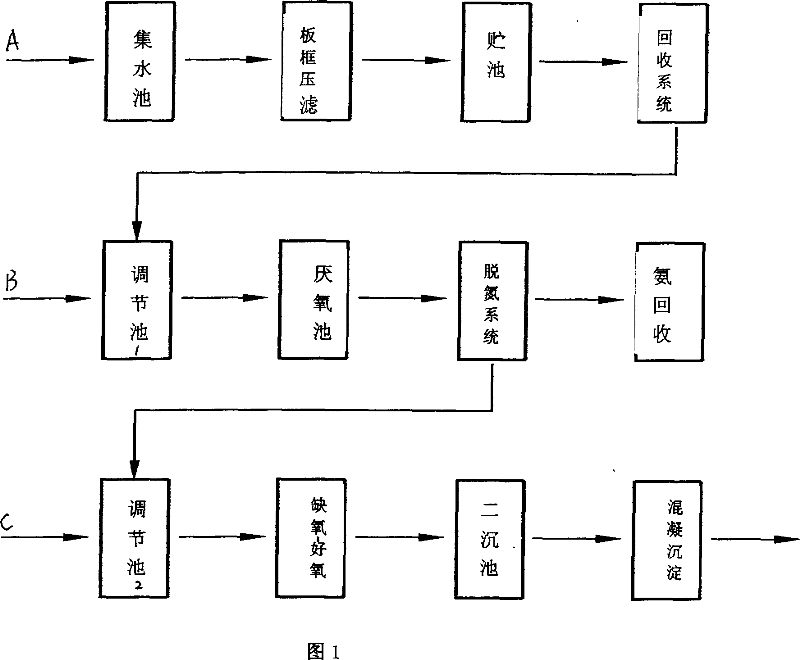

[0018] The main structures in the process flow of the artificial leather wastewater treatment method of the present invention include: the main types of wastewater are: wastewater A, tower top water B and other wastewater C collected from flushing tower water, coagulation tank, recovery tank and recovery barrel. A kind of artificial leather wastewater treatment method of the present invention comprises the following steps:

[0019] (1) Collecting pool: collect the waste water A of flushing tower water, coagulation tank, recovery tank and recycling barrel, and the volume of the sump pool is not less than the maximum discharge of any kind of waste water.

[0020] (2) Regulating pool 1: collect tower top water B, and adjust for 18 hours.

[0021] (3) Regulating pool 2: Collect mixed wastewater C, and adjust for 15 hours.

[0022] (4) DMF wastewater press filter system: The wastewater containing high concentration of DMF in the collected water passes through the filter press syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com