Construction method of subway side wall tripod single-side aluminum mold

A construction method and tripod technology, which are applied in the connection parts of formwork/formwork/work frame, artificial islands, water conservancy projects, etc. Large-scale equipment lifting and moving, etc., to achieve obvious environmental protection benefits, improve mobile flexibility and ease of use, and facilitate handling and moving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

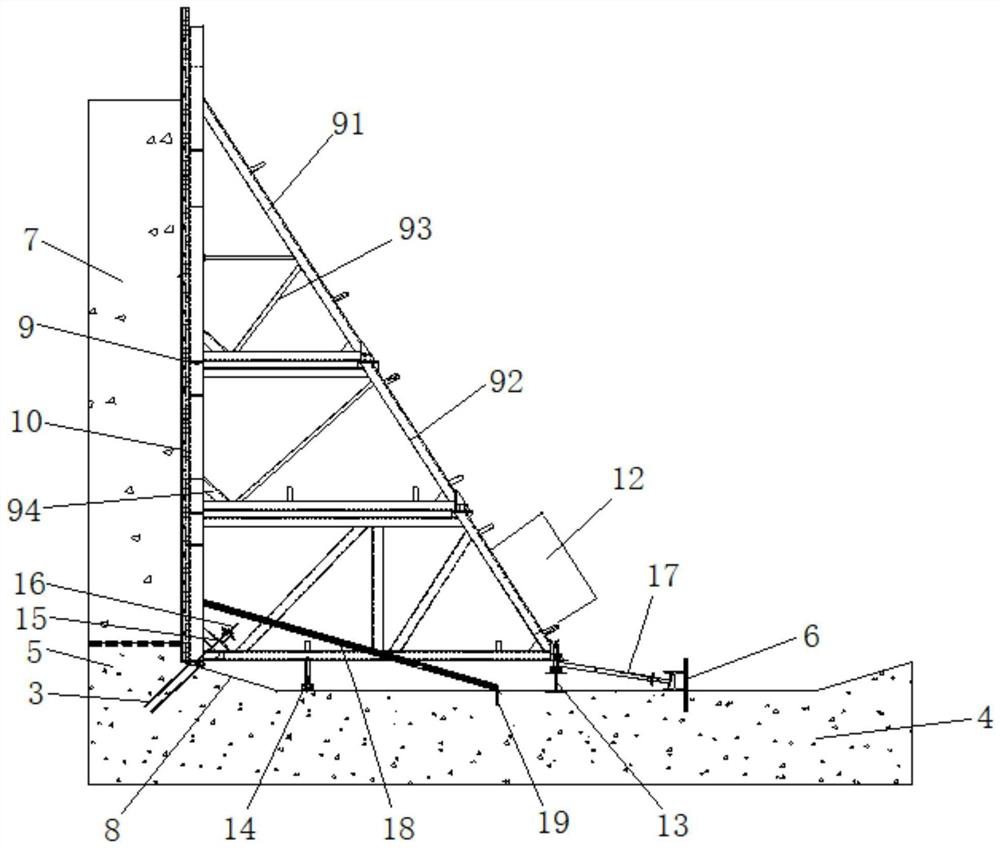

[0057] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0058] The construction method of the one-sided aluminum mold of the tripod for the subway side wall of the present invention is applied to the construction of the transfer station of Metro Line 4 and Line 5 in a certain city, wherein the part of Metro Line 4 is an underground three-story three-span structure, It is 260m long and has a maximum depth of 29.6m. The part of Line 5 is an underground two-story three-span structure with a length of 259m and a maximum depth of 21.8m.

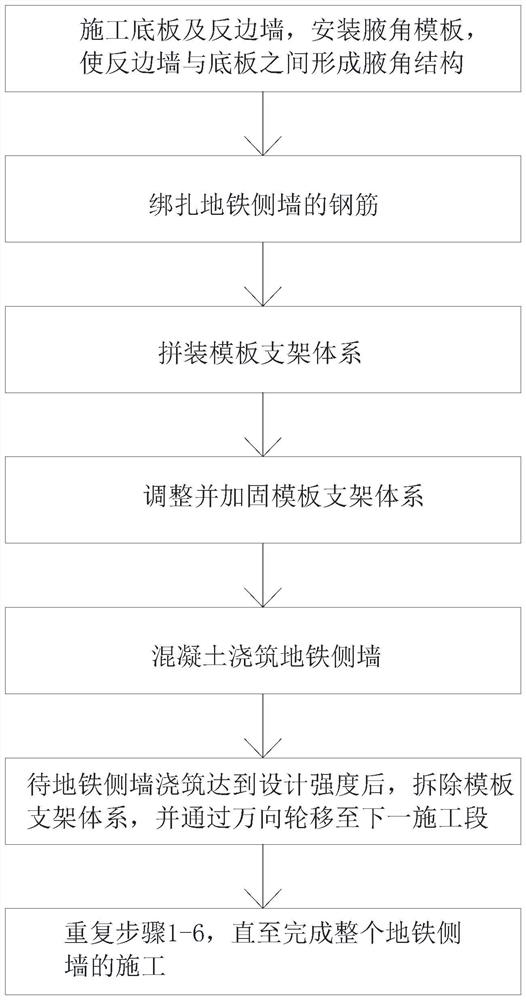

[0059] Please see attached figure 1 And attached figure 2 , a construction method of a single side aluminum formwork of a subway side wall tripod, comprising the following steps:

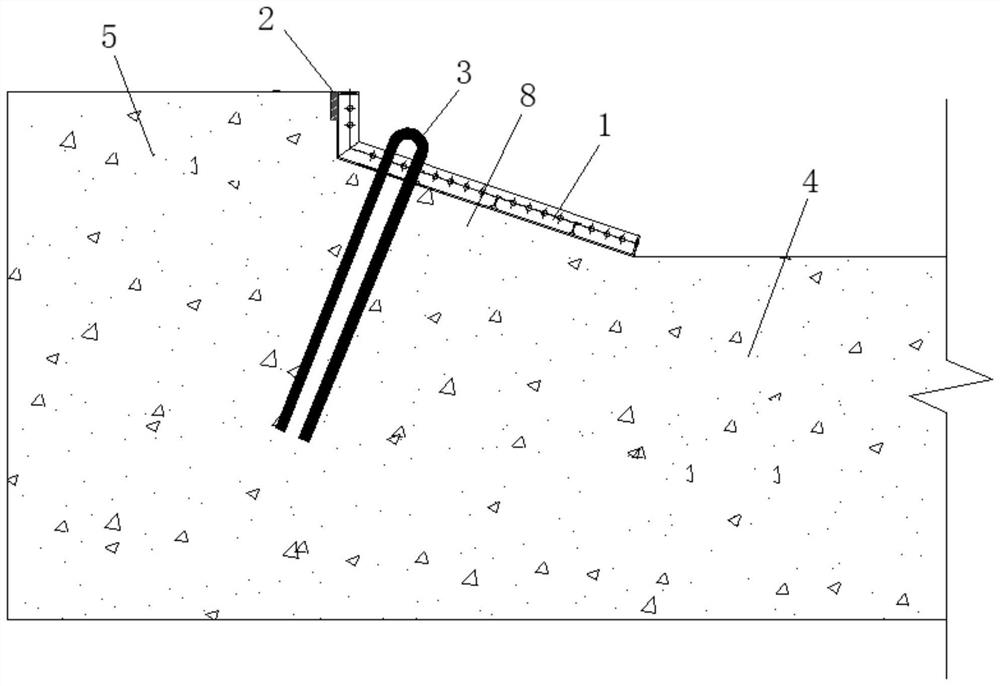

[0060] Please see attached image 3 , Step 1: construct the base plate 4 and the reverse side wall 5, the reverse side wall 5 is higher than the base plate 4, install the axillary formwork ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com