Ultrasonic atomization flue gas quenching equipment

A technology of ultrasonic atomization and flue gas quenching, which is applied in the field of flue gas purification, can solve the problems of large space occupation of flue gas quenching system, high system failure rate, unstable effect, etc., and achieves good quenching effect and atomized particle size. Small, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

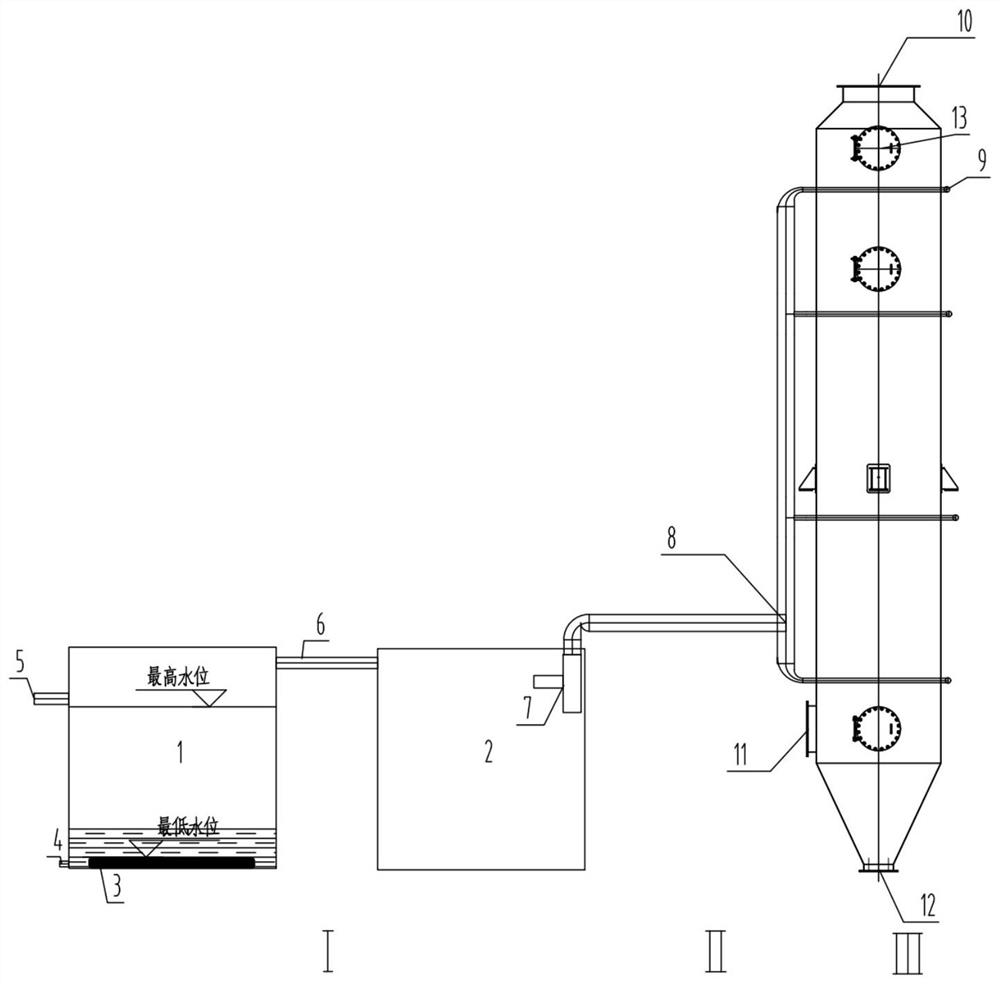

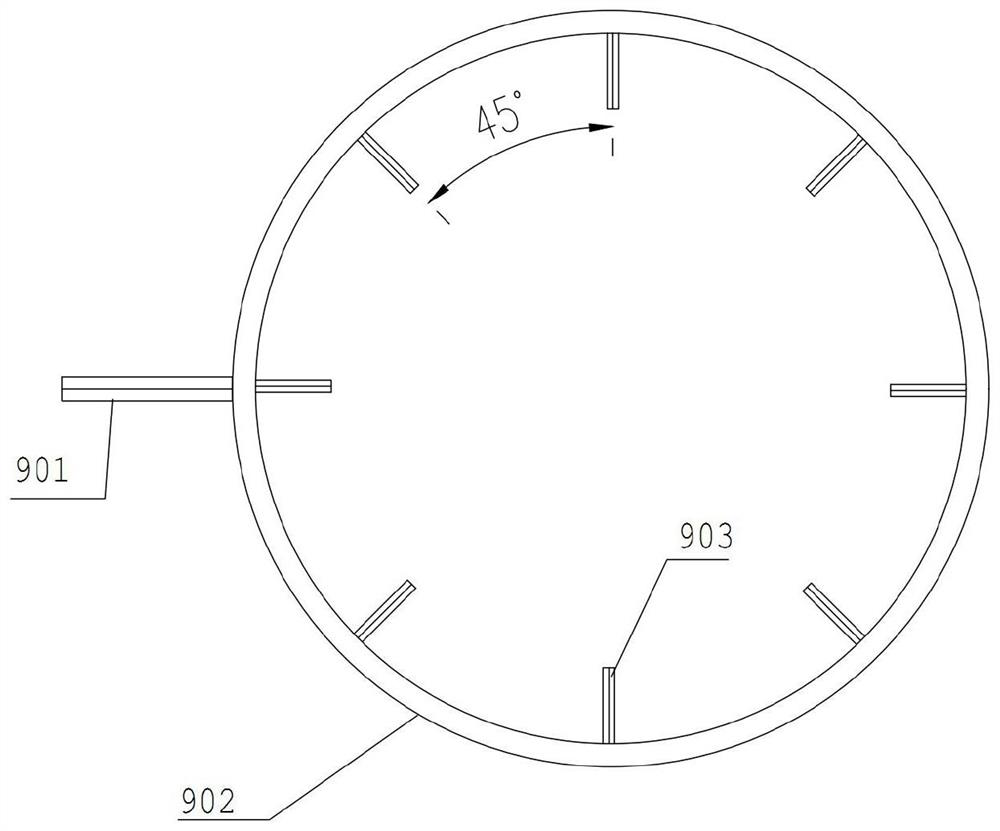

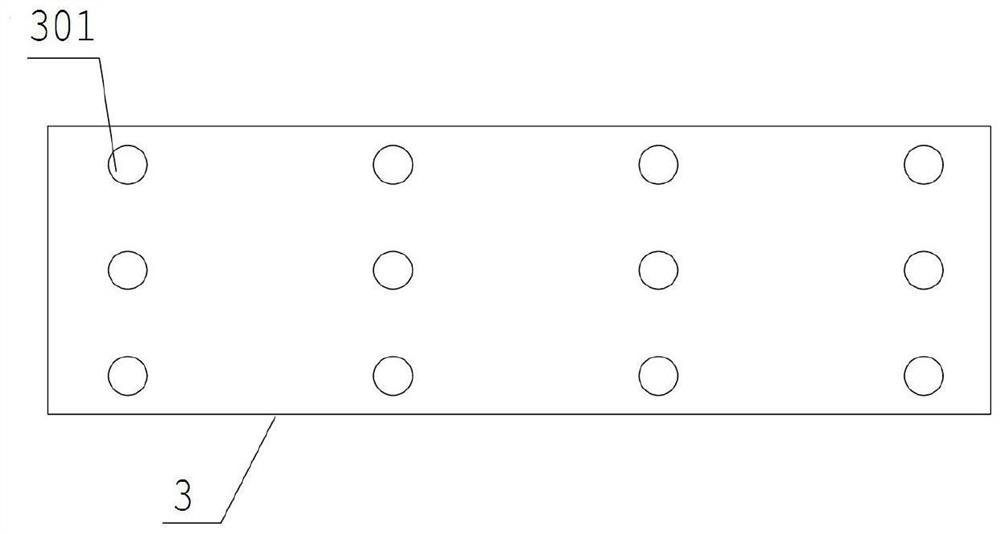

[0031] The present embodiment provides an ultrasonic atomization flue gas quenching device, the structure of which is as follows figure 1 As shown, including ultrasonic atomization system I, pipeline system II and wet quench tower III, ultrasonic atomization system I is connected with wet quench tower III through pipeline system II. The ultrasonic atomization system I includes a water storage tank 1, a water vapor atomization tank 2, an ultrasonic vibration plate 3, a discharge pipe 4, a water inlet pipe 5, a water vapor drainage pipe 6 and a fan 7. The water storage tank 1 passes through the water vapor drainage pipe 6 and the water vapor atomization. The tank 2 is connected, and the bottom of the water storage tank 1 is provided with an ultrasonic vibration plate 3 . The volume of the water storage tank 1 is 3m3, and the upper part of the water storage tank 1 is provided with a water inlet pipe 5, through which the softened water is fed to the highest water level, and the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com