Automatic detection method for friction welding head of conical component with large length-diameter ratio

A technology with automatic detection and large length-to-diameter ratio, which is applied in measuring devices, analyzing solids using sound waves/ultrasonic waves/infrasonic waves, and using sound waves/ultrasonic waves/infrasonic waves for material analysis. It can solve the problems of coaxiality and weld surface parallelism. Guarantee, waste of labor productivity, detection efficiency, safety accidents and other problems, to achieve the effect of saving labor productivity, solving difficult batch detection, and improving workpiece detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

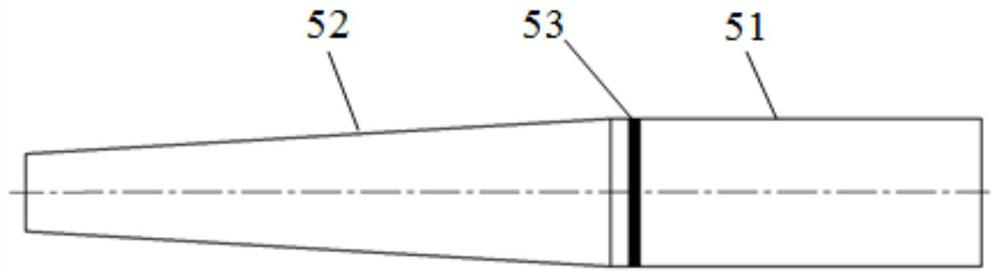

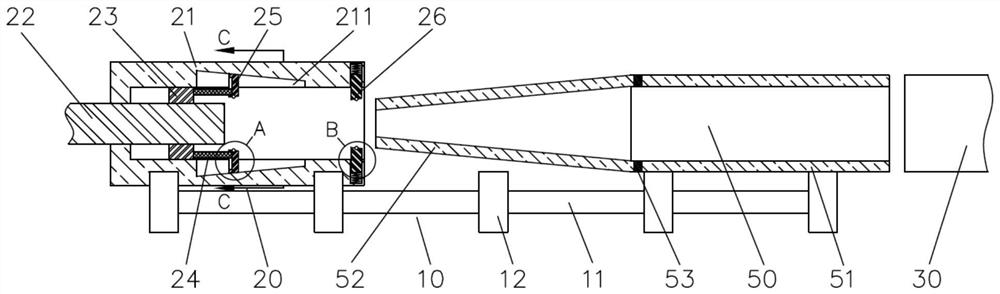

[0041] like Figures 1 to 7 As shown in the figure, an automatic detection method for a friction welded joint of a tapered member with a large aspect ratio is used for a friction welded joint of a tapered member with a large aspect ratio composed of a tapered end 52 and a cylindrical end 51. The whole automatic detection system is controlled by industrial computer. The automatic detection system includes the equipment water tank, the guide rail assembly 10, the profiling positioning tool 20, the first push rod 30, the clamping loading and unloading tool 40 and the water immersion ultrasonic C scanning equipment; guide rail; The assembly 10 is arranged at the bottom of the equipment water tank, and includes a driving shaft 11 and a rotating roller 12, and the rotating roller 12 is evenly sleeved on the outer wall of the driving shaft 11;

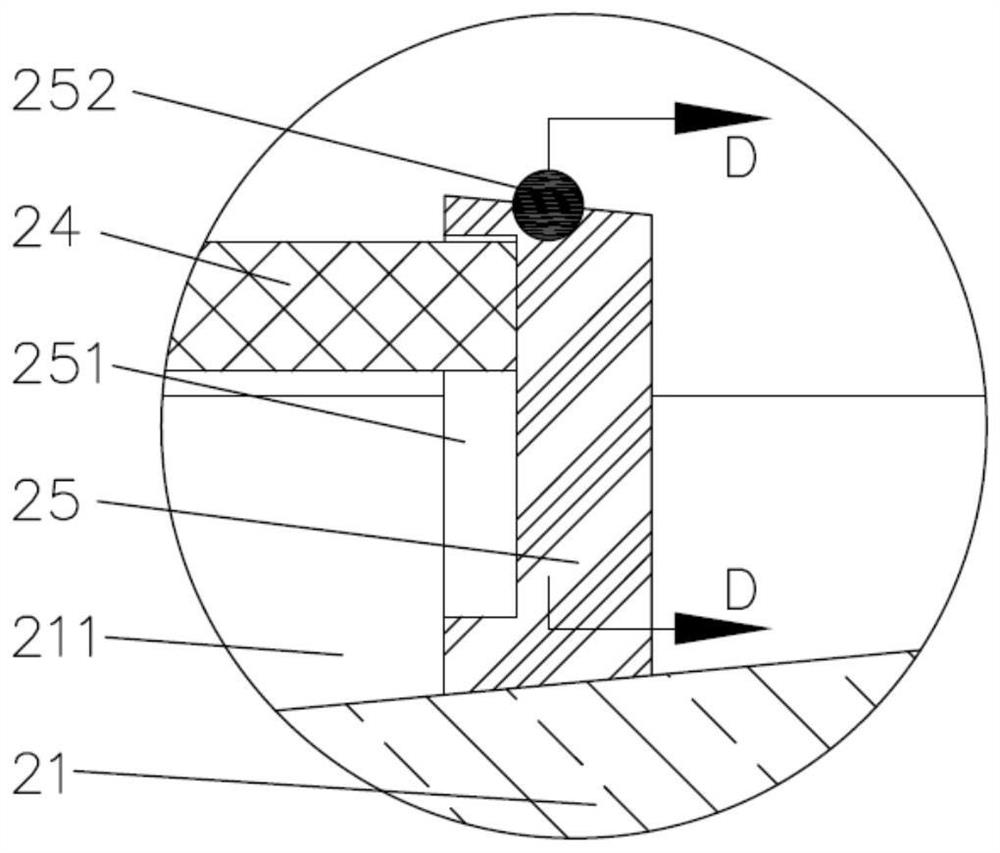

[0042] The profiling positioning tool 20 is arranged at one end of the guide rail assembly 10, and includes a tool body 21, a second push ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| arm length | aaaaa | aaaaa |

| suction force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com