Forming method of semiconductor structure

A technology of semiconductor and dielectric structure, applied in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problem of shrinking fin channel size, inability to meet device performance requirements, and reducing fin field effect transistor operating current, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

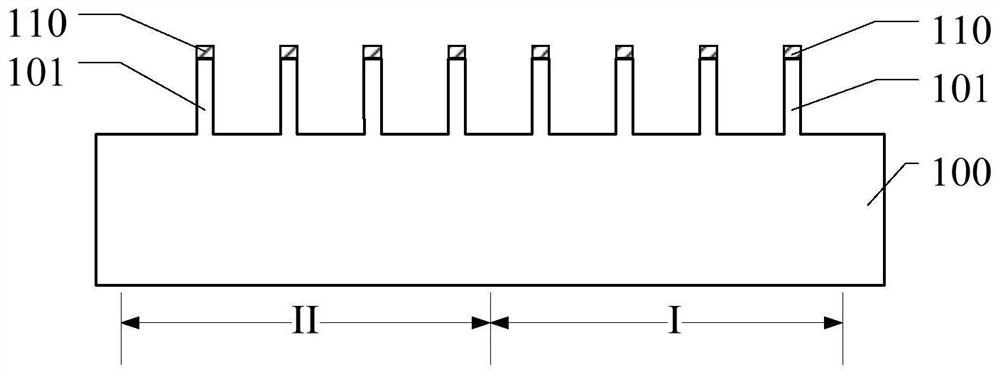

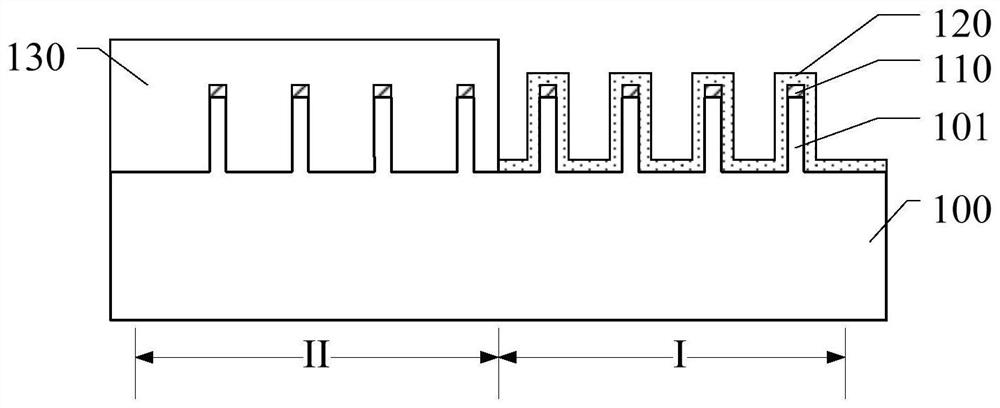

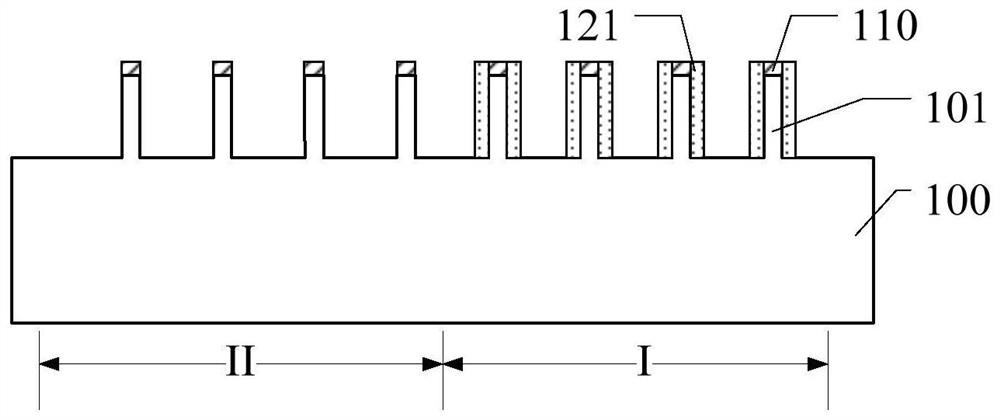

[0028] As mentioned in the background, in order to realize a semiconductor structure with strained fins to meet higher device density and meet device performance requirements, it is urgent to propose a semiconductor structure with strained fins Methods.

[0029] In order to solve the above problems, the technical solution of the present invention provides a method for forming a semiconductor structure, by forming a second strained fin on the sidewall surface of the initial first fin on the first region, and using the second strained fin as a mask, Etching the initial substrate and the initial first fins of the first region can form second invalid fins located between the substrate of the first region and the second strained fins, and, in each second invalid fin Between the adjacent second strained fins, an isolation opening extending into the second invalid fin is formed, which provides a method for forming a semiconductor structure with strained fins, and on this basis, the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com