Thermal insulation structure integrated composite non-dismantling formwork and preparation method thereof

A technology that does not need to dismantle formwork and thermal insulation board is applied in the field of building thermal insulation materials, which can solve the problems of occupying a large workshop space, large investment in maintenance equipment, and large weight of protective layer, so as to reduce equipment investment, reduce plant site consumption, and achieve good fire performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

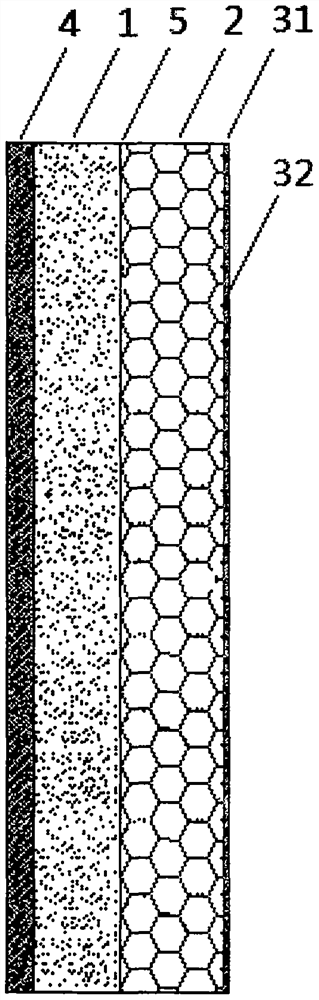

[0034] refer to figure 1 , figure 2 , a composite non-demolition formwork with integrated thermal insulation structure, comprising: A-grade thermal insulation board 1, B-grade thermal insulation board 2, inner protective layer 3, outer protective layer 4 and adhesive 5;

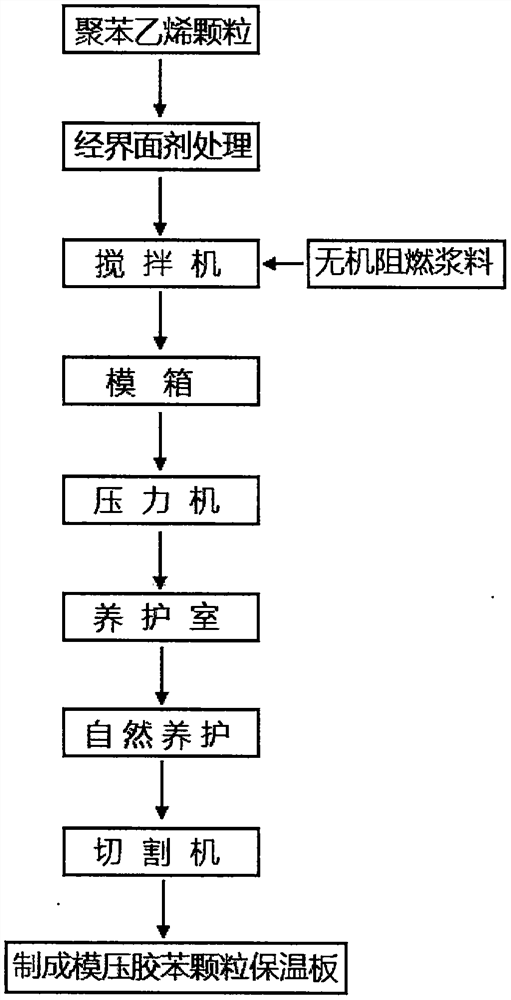

[0035] The A-level insulation board 1 is a molded inorganic rubber benzene particle insulation board, including: polystyrene particles, interface agent and inorganic flame-retardant slurry; the polystyrene particles are flame-retardant expanded polystyrene particles or flame-retardant expanded graphite polystyrene particles; the interface agent is one or more of VAE aqueous solution, PVA aqueous solution, PEG aqueous solution, methyl silicate aqueous solution, and phenolic resin; the inorganic flame-retardant The slurry includes the following components by weight: 100 parts by weight of cement, 10-50 parts by weight of fly ash, 5-25 parts by weight of stone powder, 2-10 parts by weight of inorganic silica f...

Embodiment 2

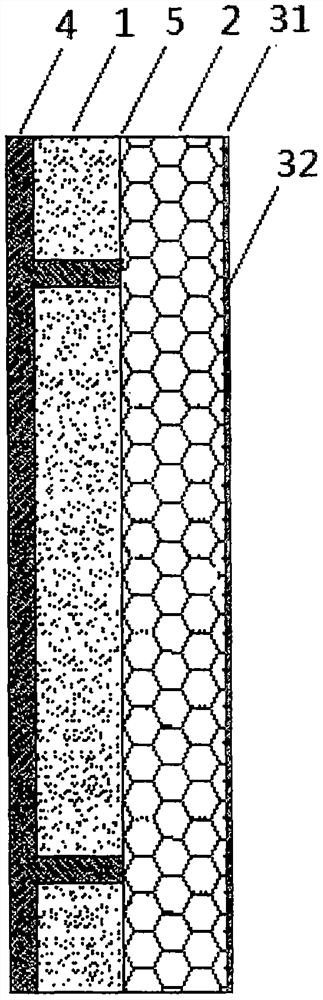

[0052] refer to image 3 , the A-level insulation board 1 bonded with the B-level insulation board 2 is a plurality of pieces, the width of the board gap is 10 mm to 20 mm, and the polymer insulation mortar is filled in the board gap to form a reinforcing rib, and the multi-piece A The grade insulation board is bonded into one.

Embodiment 3

[0054] refer to Figure 5 , the outer protective layer adopts cement-based cloth and steel wire mesh to replace the polymer mortar with built-in glass fiber mesh cloth, which can realize maintenance-free production, and uses adhesive to bond the cement-based cloth 41 with the A-grade The insulation board 1 is bonded, and a steel wire mesh 42 is set between the cement base cloth 41 and the A-grade insulation board 1. In order to increase the strength, the cement base cloth should adopt a non-woven fabric with higher tensile strength.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com