Grinding wheel mesh heating and cutting method

A cutting method and a grinding wheel technology, which are applied in metal processing, metal processing equipment, grinding devices, etc., can solve the problems of flash or white edges on the grinding wheel mesh, low quality of the finished grinding wheel, and affecting the bonding strength, etc., and achieve improved heating. Effect and heat preservation effect, reduce heating cost, and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

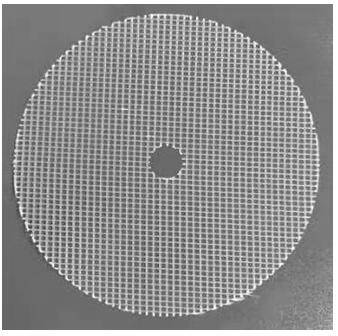

[0047] The cutting and forming of the grinding wheel mesh on the adhesive cloth of the low-weight grinding wheel mesh includes the following steps:

[0048] S1: Grinding wheel net adhesive tape conveying: convey the grinding wheel net adhesive tape to the felt conveyor belt 1, the grinding wheel net adhesive tape is 8 mesh 125g low-gram weight grinding wheel net adhesive tape;

[0049] S2: Adjust the spacing: adjust the spacing between the heating component and the felt conveyor belt 1 to 20mm;

[0050] S3: Heating and keeping warm: turn on the heating component, adjust the conveying speed of the felt conveyor belt 1 to 500mm / s, and heat the felt conveyor belt 1 to 30°C through the heating component, so that the temperature difference between the upper and lower surfaces of the adhesive cloth on the grinding wheel net is ΔT=1°C, and insulation;

[0051] S4: Cutting and forming: the felt conveyor belt 1 transmits the heated and heat-preserved adhesive cloth on the grinding whe...

Embodiment 2

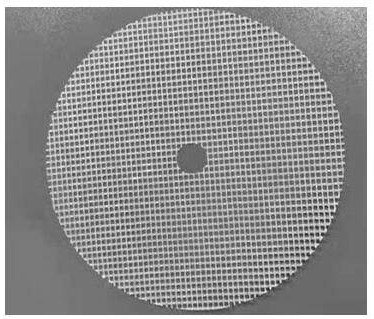

[0053] The cutting and forming of the grinding wheel mesh on the adhesive cloth of the low-weight grinding wheel mesh includes the following steps:

[0054] S1: Conveying the adhesive tape on the grinding wheel: convey the adhesive cloth on the grinding wheel to the felt conveyor belt 1, the adhesive cloth on the grinding wheel is 14-mesh 85g low-weight grinding wheel adhesive;

[0055] S2: Adjust the spacing: adjust the spacing between the heating component and the felt conveyor belt 1 to 15mm;

[0056] S3: Heating and keeping warm: turn on the heating component, adjust the transmission speed of the felt conveyor belt 1 to 680mm / s, and heat the felt conveyor belt 1 to 30°C through the heating component, so that the temperature difference between the upper and lower surfaces of the adhesive cloth on the grinding wheel net is ΔT=1°C, and insulation;

[0057] S4: Cutting and forming: the felt conveyor belt 1 transmits the heated and heat-preserved adhesive tape on the grinding ...

Embodiment 3

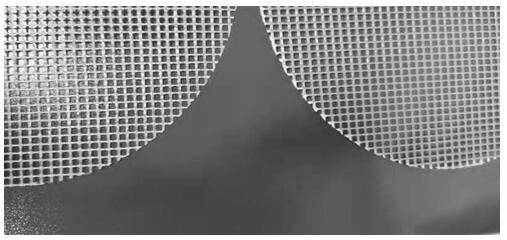

[0059] The cutting and forming of the grinding wheel mesh on the medium-weight grinding wheel mesh includes the following steps:

[0060] S1: Grinding wheel net adhesive tape conveying: transport the grinding wheel net adhesive tape to the felt conveyor belt 1, the grinding wheel net adhesive tape is 6 mesh 190g medium weight grinding wheel net adhesive tape;

[0061] S2: Adjust the spacing: adjust the spacing between the heating component and the felt conveyor belt 1 to 15mm;

[0062] S3: Heating and keeping warm: turn on the heating component, adjust the conveying speed of the felt conveyor belt 1 to 635mm / s, and heat the felt conveyor belt 1 to 45°C through the heating component, so that the temperature difference between the upper and lower surfaces of the adhesive cloth on the grinding wheel net is ΔT=1°C, and insulation;

[0063] S4: Cutting and forming: the felt conveyor belt 1 transmits the heated and heat-preserved adhesive tape on the grinding wheel net to the cutti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com