Explosive and powder flaking production system

A production system and technology of explosives, applied in the field of explosives tablet production system, can solve the problems of low production automation, hidden safety hazards, low production efficiency, etc., and achieve the effect of ingenious structure, safe and convenient use, and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

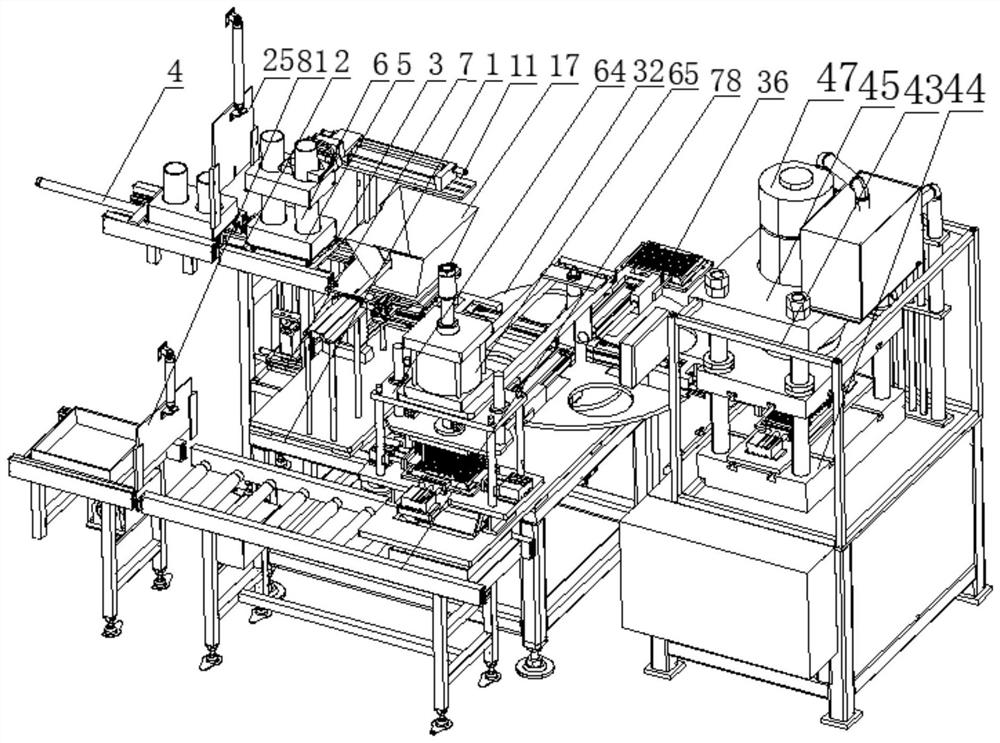

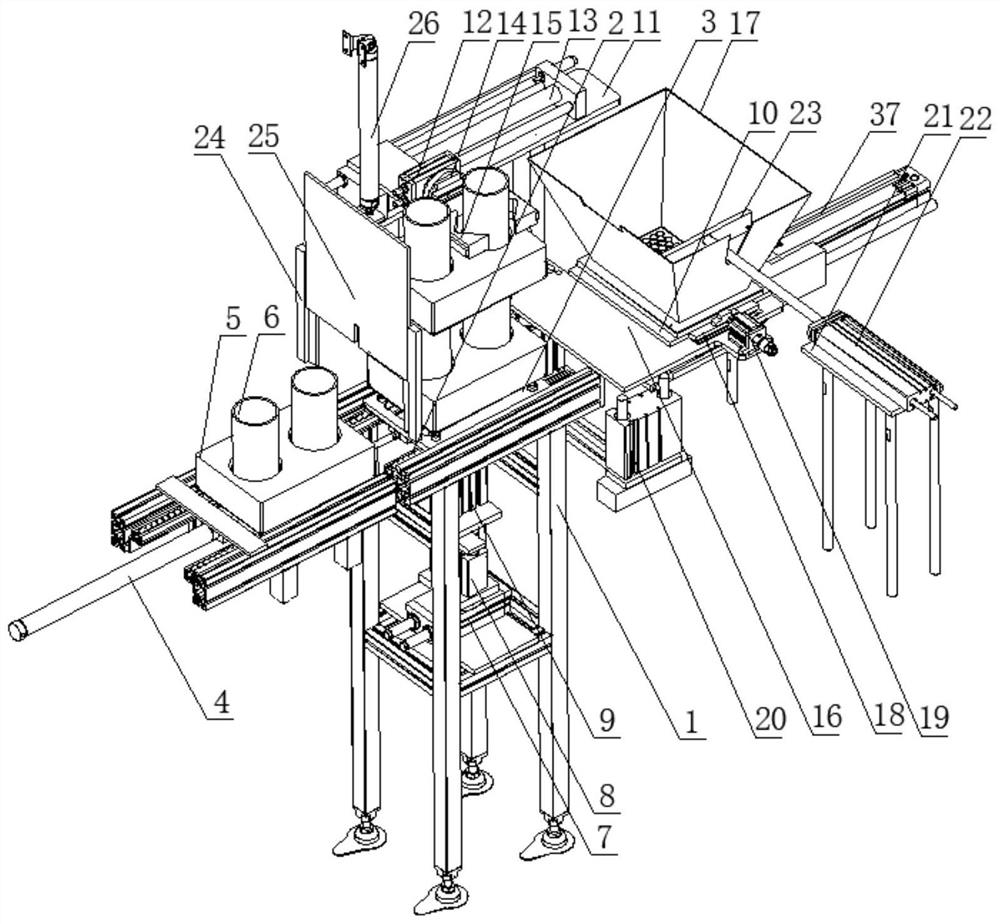

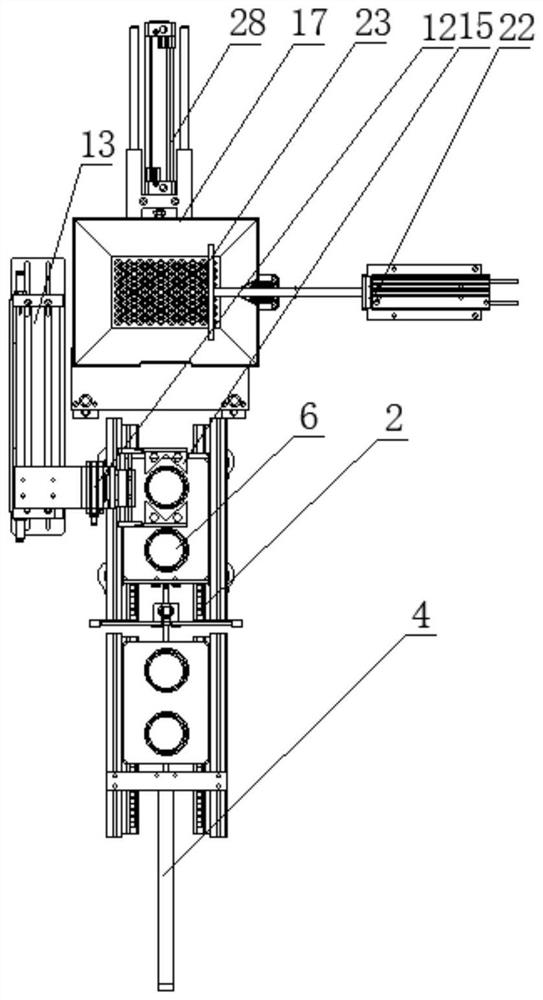

[0035] Such as figure 1 The shown propellant tablet production system includes a frame 1, a charging and distributing device connected to the frame 1, and a transfer device connected to the frame 1 to transfer the propellant to different stations, located on the frame 1 On one side, the propellant and explosive that are sub-installed in the mold are pressed into a sheet-shaped pressing and forming device, connected with the frame 1, and the sheet-discharging device that takes out the compressed propellant and explosive from the mould. see Figure 2 to Figure 4 , the charging and dispensing device comprises a delivery track 2 connected to the frame 1, a medicine box box delivery frame 3 that can move along the delivery track 2, a cylinder seat is connected with the frame 1, and a telescopic rod is connected with the medi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com