Steel drum air pressure adjusting system and method for beverage production

An air pressure regulating system and steel drum technology, applied in the preparation of alcoholic beverages, etc., can solve the problems of extrusion deformation of fermenters and valves, affect the quality of beverage fermentation, and reduce service life, so as to increase service life, stabilize air pressure, The effect of improving the quality of fruit wine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

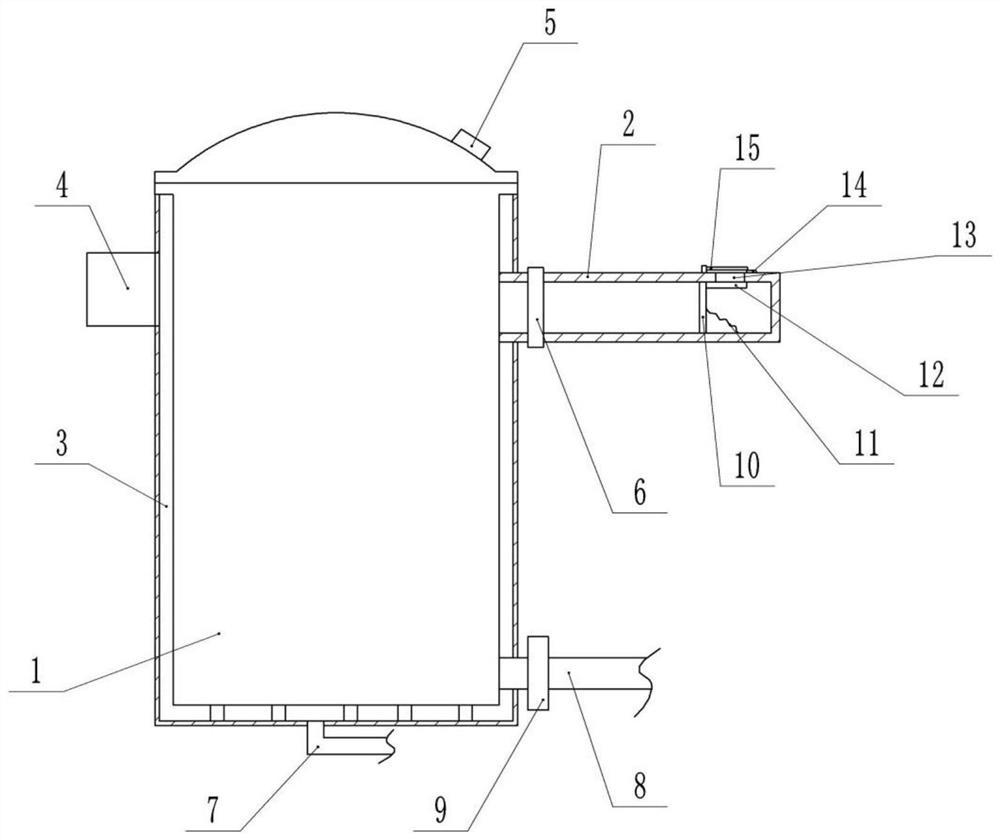

[0026] as attached figure 1 As shown, a steel drum air pressure adjustment system for beverage production includes: a fermenter 1 and an air pressure sensor, the air pressure sensor is fixed on the inner wall of the fermenter 1 by bolts, and also includes: a controller and a sensor for detecting the pH of the fermented liquid PH value sensor, the PH value sensor is fixedly installed on the inner wall of the fermentation tank 1 by bolts, the controller is electrically connected with the PH value sensor and the air pressure sensor, and the controller is specifically a single-chip microcomputer of stm32f103c8t6 for the specific controller.

[0027]The fermentation tank 1 includes an inner chamber and an outer chamber. The bottom of the inner chamber is welded together with the outer chamber through a connecting column. A cooling chamber 3 is provided between the inner chamber and the outer chamber. The cooling chamber 3 is connected to a cooling pump 4, which is connected by a bol...

Embodiment 2

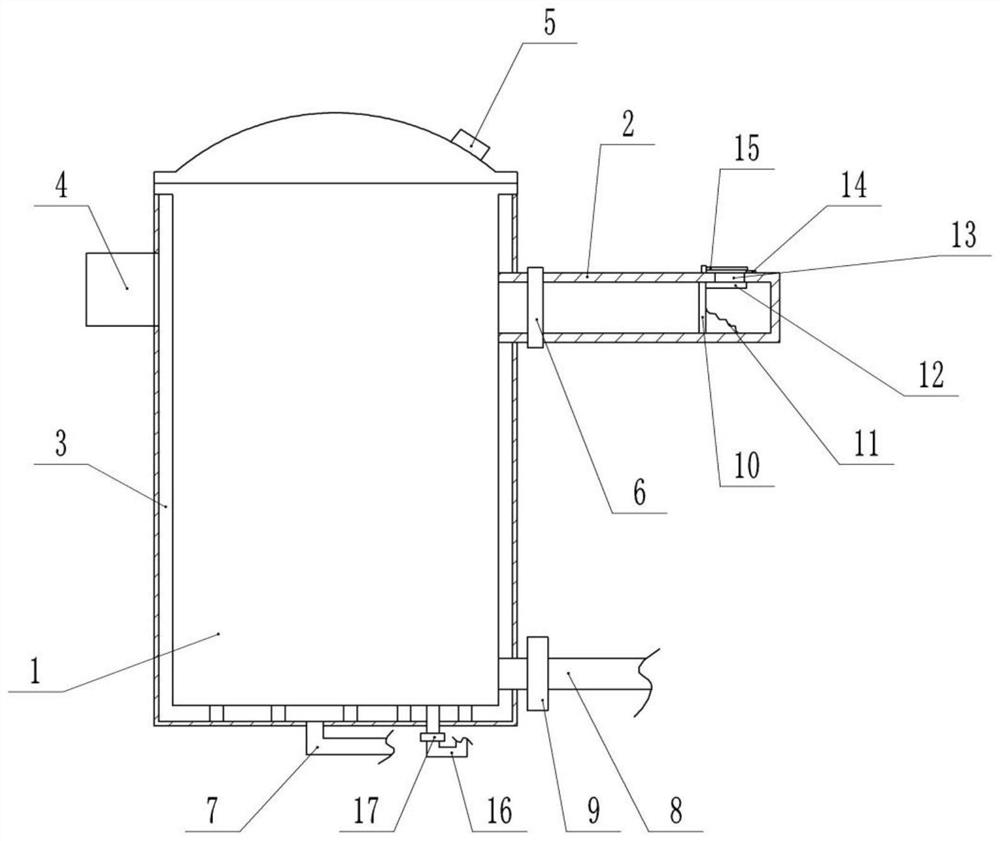

[0043] The difference between this embodiment and embodiment 1 is that, as attached figure 2 As shown, it also includes: the bottom of the inner warehouse is provided with an inflation port, the inflation port is provided with a fourth valve 17, the switch of the fourth valve 17 is electrically connected to the controller, the inflation port is connected with an inflation tube 16, and the inflation tube 16 passes through the There is a nitrogen tank or a carbon dioxide tank connected to the outer warehouse.

[0044] During the initial fermentation of the fermentation broth, low-temperature fermentation is required, and the temperature of the fermentation environment will be low. During low-temperature fermentation, some water vapor will condense into water droplets on the top of the fermenter 1, and the water droplets will fall to the upper surface of the fermentation broth, making the fermentation Uneven liquid concentration affects the quality of fruit wine. The fermentati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com