Silk batik device

A batik and silk technology, applied in dyeing method, equipment configuration for processing textile materials, textiles and papermaking, etc., can solve the problems of difficulty in accurately controlling the temperature of wax liquid, inability to guarantee the quality of batik, high labor intensity, etc., to achieve simple structure, batik Improved efficiency and uniform wax output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

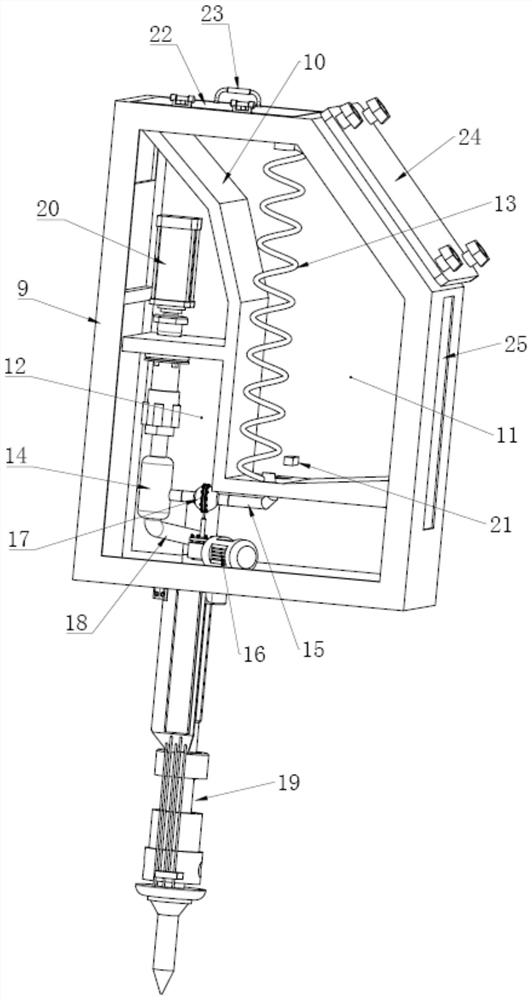

[0050] Such as Figure 5 As shown, the structure of this embodiment is the same as that of Embodiment 1, the difference is that there is a chute 101 on the frame 1, and a flat cloth board 26 is arranged between the two correspondingly arranged chute 101, and the flat cloth board 26 passes through the chute 101 is slidably arranged on the frame 1. During use, after the base cloth is placed under the batik box 9, the flat cloth plate 26 is pushed from one end of the frame 1 to the other end, so that the base cloth can be leveled to ensure that the base cloth has no wrinkles. Carrying out batik further ensures the batik quality of the base cloth.

Embodiment 3

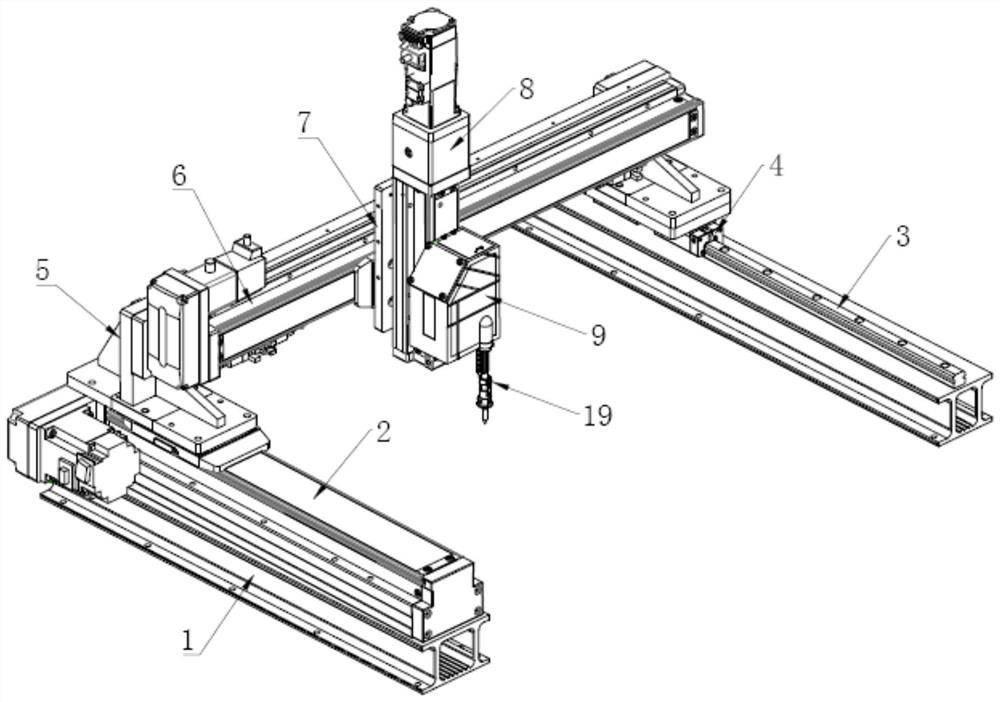

[0052] Such as Figure 6 As shown, the structure of this embodiment is the same as that of Embodiment 1, the difference is that the driving mode of the displacement of the batik box 9 is different. A slide bar 31 driven by the first drive motor 28 is slidably installed, and a wax box installation block 35 driven by the second drive motor 32 is slidably installed on the slide bar 31 along the Y-axis direction, and the batik box 9 is fixedly installed on the wax box installation block 35 superior.

[0053] In the present embodiment, the first thread shaft 29 is rotatably installed on the installation base 27, and the first guide rod 30 arranged parallel to the first thread shaft 29 is also provided on the installation base 27, and the slide bar 31 passes through the first guide rod. 30 is slidably installed on the installation base 27, and the slide bar 31 is threadedly connected with the first silk shaft 29, and the first driving motor 28 is fixedly installed on one end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com