Method for detecting ultra-high-purity germanium single crystal < 100 > crystal orientation defect

A detection method and germanium single crystal technology, applied in the direction of measuring device, test crystal, test sample preparation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Step 1, taking slices: take a single wafer with a thickness of 3 mm from both ends of the ultra-high-purity germanium single crystal purity-qualified crystal section, and mill and grind one side of the single wafer to make it smooth;

[0041] Step 2, configure the corrosion solution: nitric acid: hydrofluoric acid: 10% copper nitrate = 1:2:1;

[0042] Step 3: Etching the single wafer: put the single wafer into the etching solution, with the flat and smooth side facing upwards, and rotate the single wafer in the same direction at a speed of 125r / min for 5 minutes to etch out uniform bright spots;

[0043] Step 4, cleaning and drying: clean the corroded single wafer with pure water, and dry it with nitrogen;

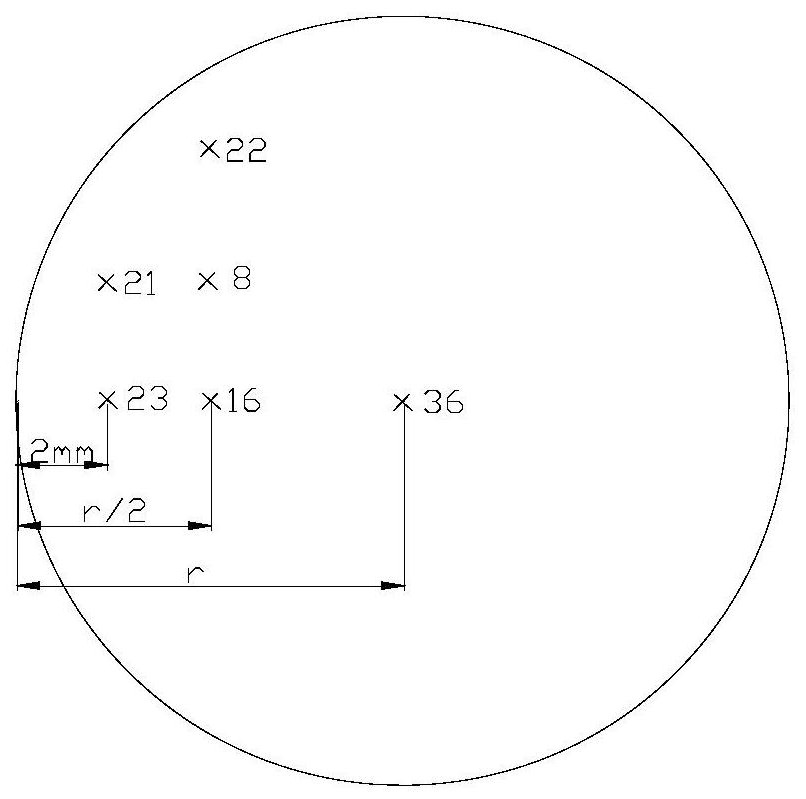

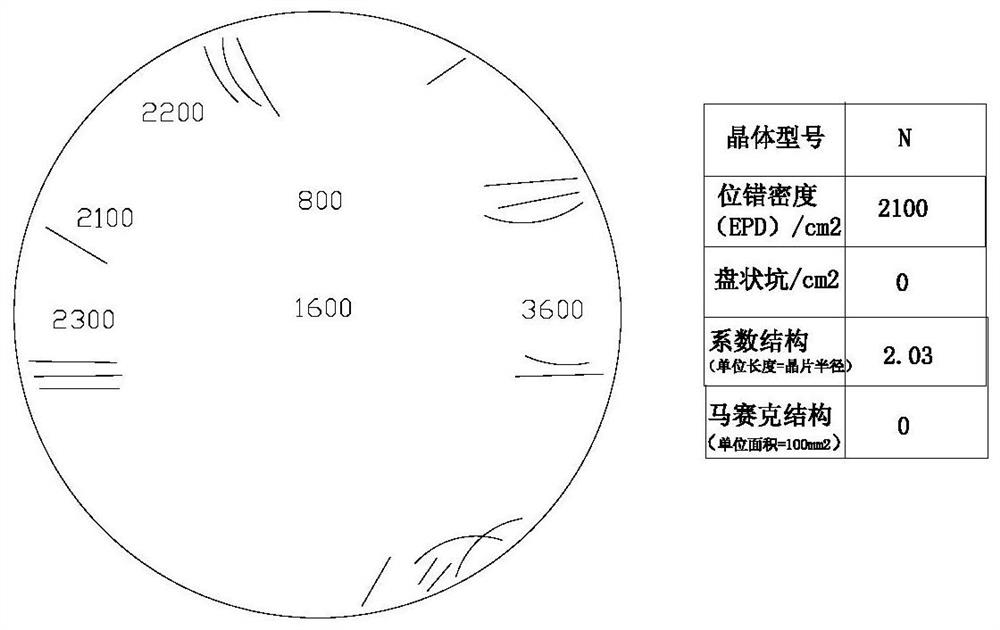

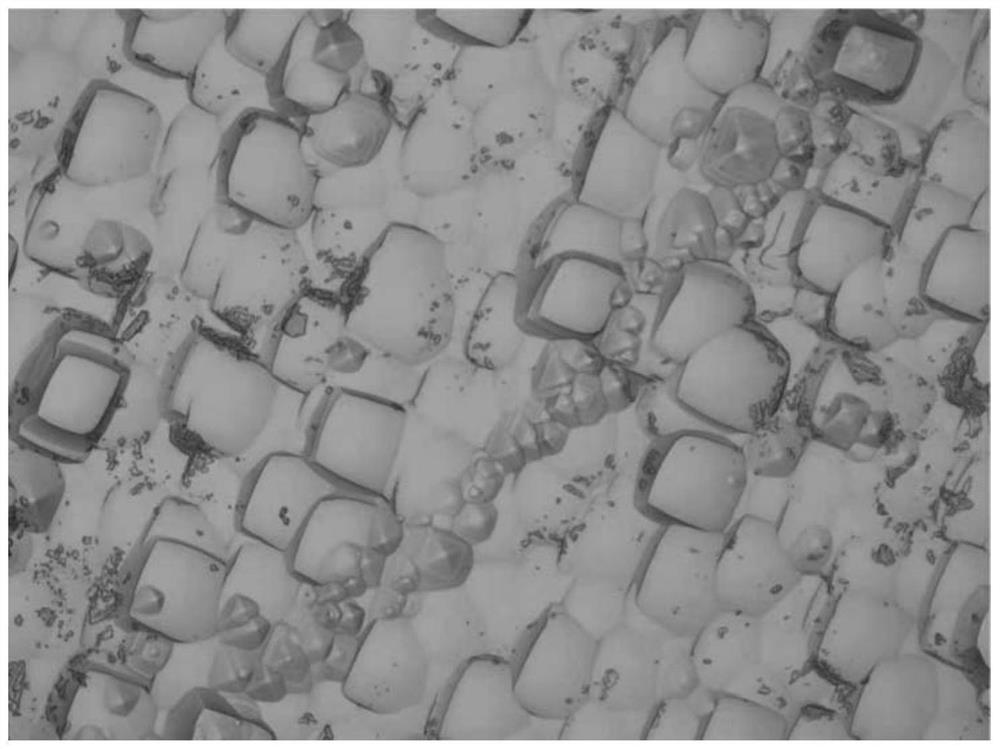

[0044] Step 5, detection: it is observed that the surface of the single wafer contains defects, and it is confirmed with a metallographic microscope that it is a coefficient structure (such as image 3 ), and record the distribution and quantity of its defects on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com