Fuel cell liquid water self-adaptive flow field plate capable of automatically switching between parallel flow field and snakelike flow field

A fuel cell and self-adaptive flow technology, which is applied to fuel cells, circuits, electrical components, etc., can solve the problems of increased pump power consumption, large pressure drop, and increased two-phase flow resistance, so as to reduce pump power consumption, Avoid local flooding and reduce flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and case the specific embodiment of the present invention is described further:

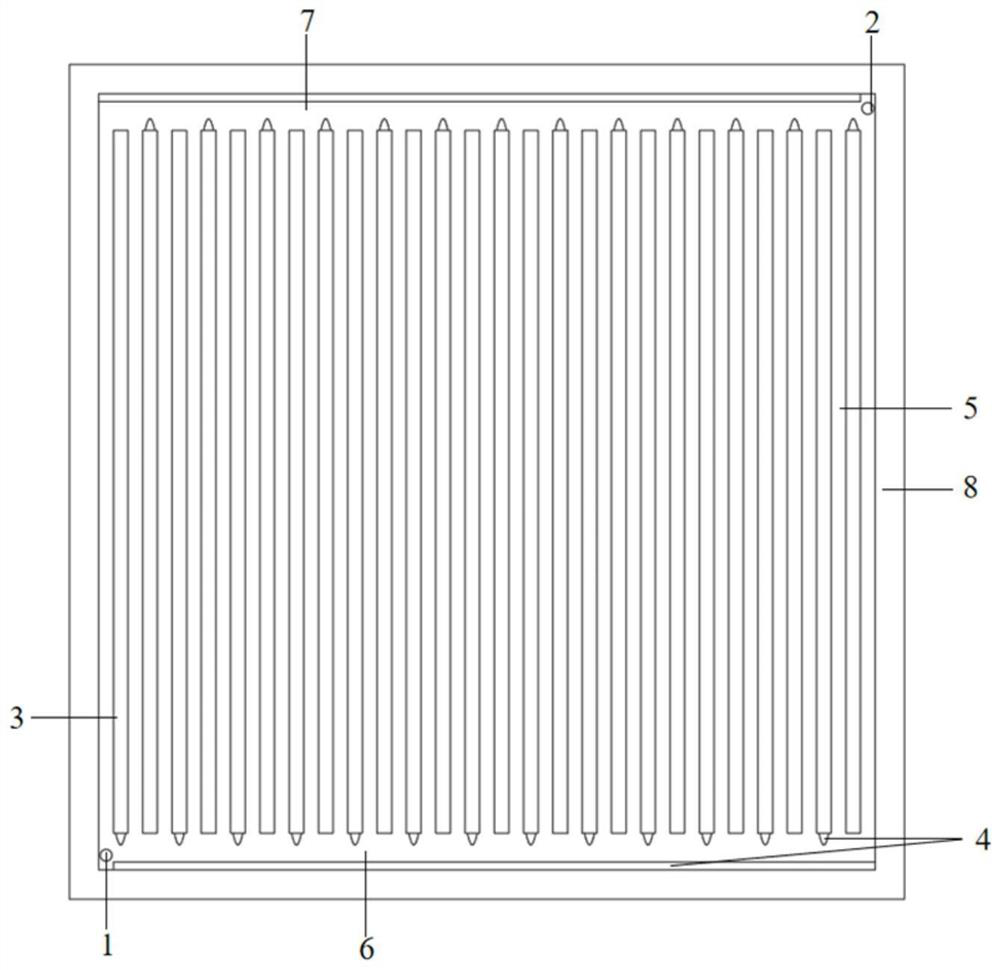

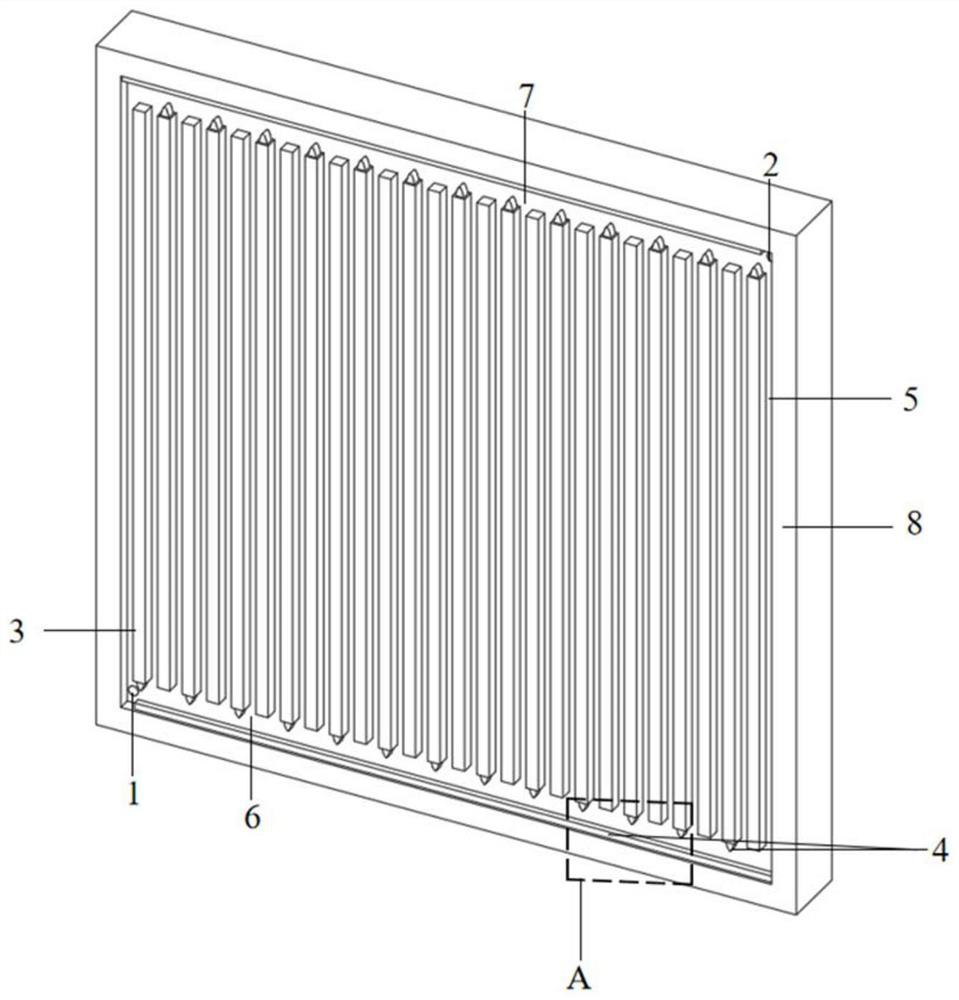

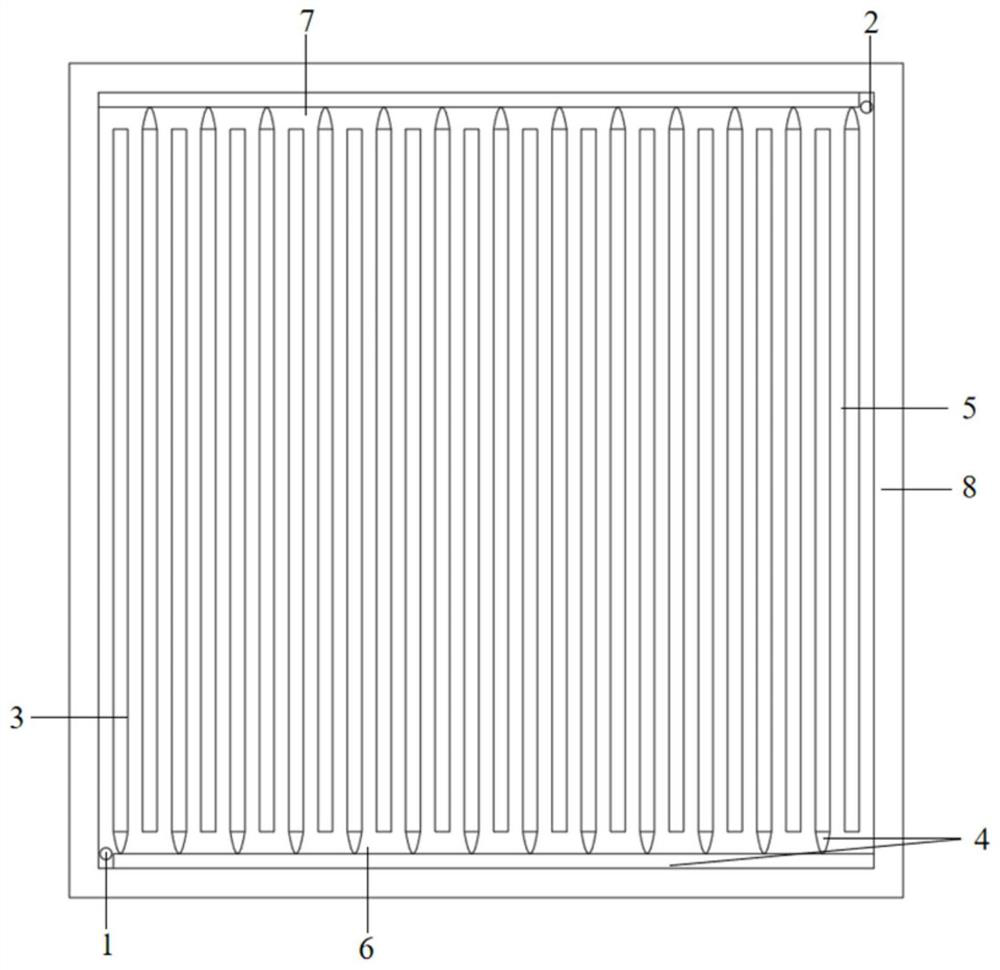

[0026] Such as figure 1 with figure 2 As shown, adaptive structures 4 are arranged on both sides of the main inlet pipe 6 and the main outlet pipe 7, so that the flow field has a certain ability to adapt to liquid water. The reactant enters the inlet manifold 6 from the inlet 1 of the cathode and anode plates respectively, and then enters the flow channel 5 formed between adjacent ridges 3 , collects in the outlet manifold 7 , and flows out from the outlet 2 . During the whole flow process, the reaction gas is transported to the catalytic layer through the diffusion layer for electrochemical reaction, and the generated liquid water enters the flow channel 5, the inlet main pipe 6 and the outlet main pipe 7 through the diffusion layer. When the liquid water passes through the self-adaptive structure 4 on the side of the ridge 3 along with th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com