Automobile exhaust waste heat power generation device capable of enhancing heat transfer

A technology of waste heat power generation and automobile exhaust, which is applied in the direction of power plant, generator/motor, and power plant gas intake, etc., which can solve the problem of low heat transfer coefficient of exhaust pipe and heat exchanger, large space and heat transfer area. , low energy conversion efficiency and other problems, to achieve the effect of improving fuel economy, increasing heat transfer area, and increasing total power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

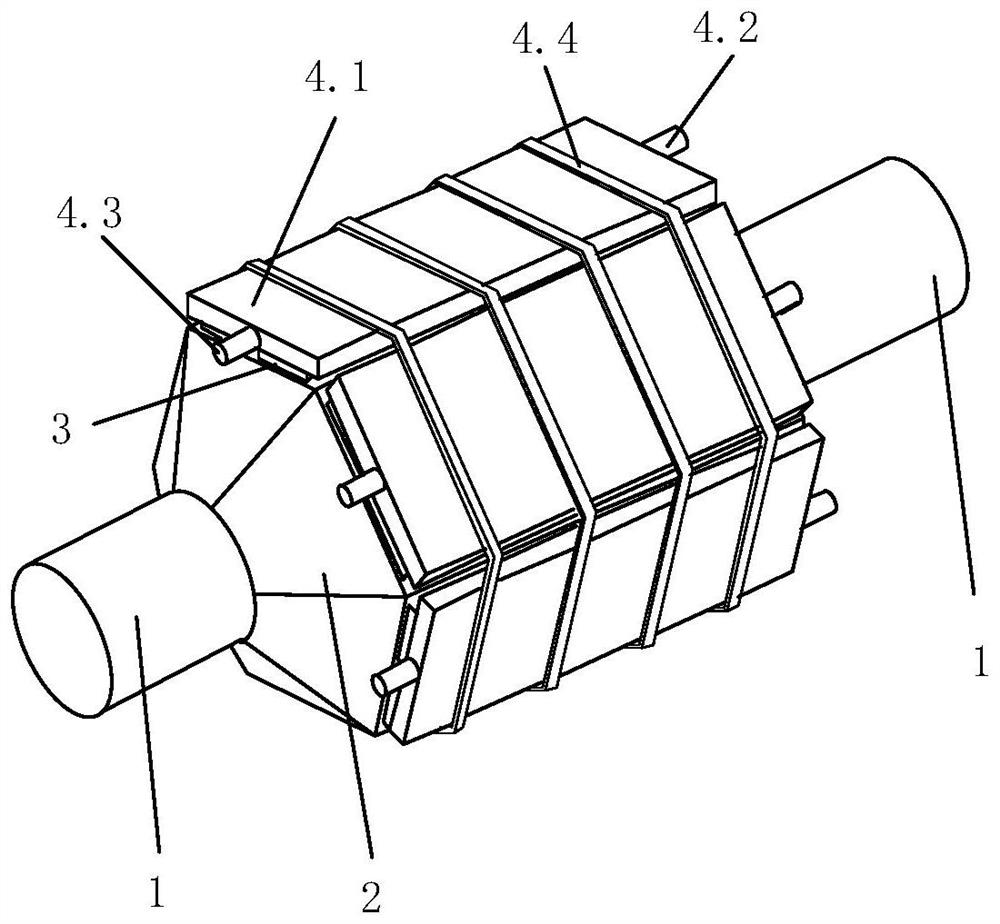

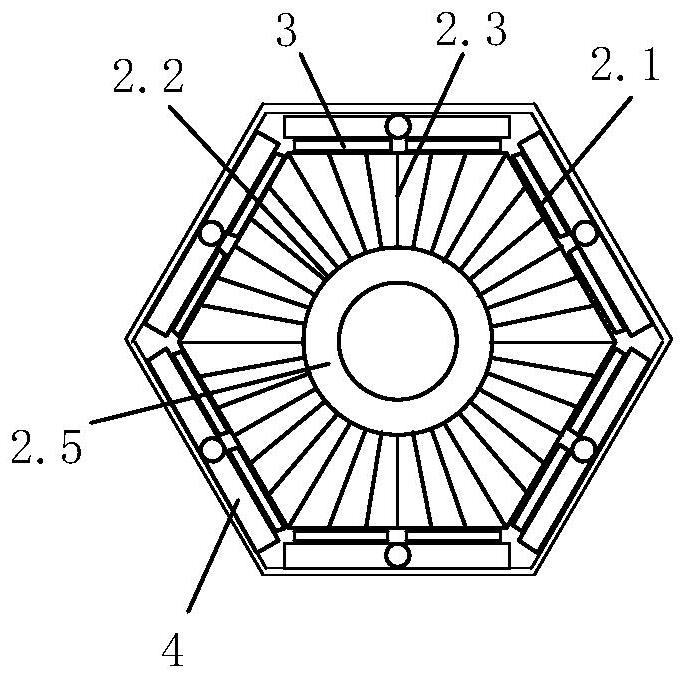

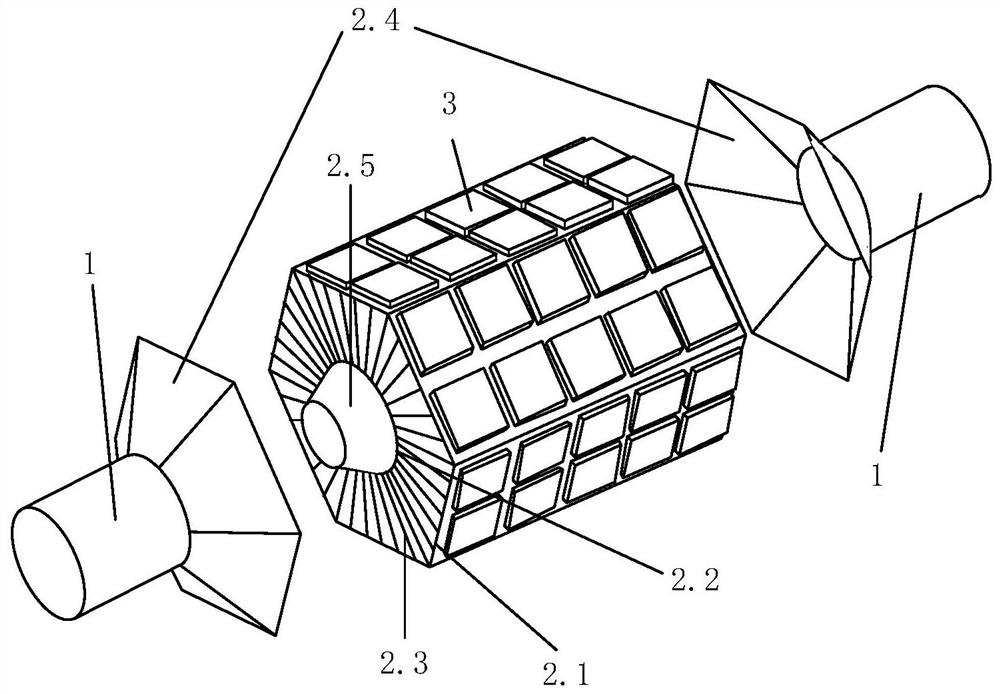

[0055] This embodiment provides an automobile exhaust waste heat power generation device that enhances heat transfer. The automobile exhaust pipe 1 is connected to the polygonal outer pipe body 2.1 through a different diameter pipe 2.4, and the inlet and outlet ends of the heat exchange assembly 2 are respectively connected to the automobile engine. The exhaust pipe 1 and the muffler of the exhaust pipe 1 are connected; the polygonal outer pipe body 2.1 is provided with a hollow inner pipe body 2.2 sealed at both ends, and the inner pipe body 2.2 is connected to the polygonal outer pipe through its external radial guide fins 2.3 The body 2.1 is connected, and the inner pipe body 2.2 and the polygonal outer pipe body 2.1 and the guide fins 2.3 form a storage space for the vehicle exhaust; the air inlet side of the inner pipe body 2.2 is provided with a conical guide ring 2.5; The outer wall of the tube body 2.1 and one side of the thermoelectric module 3 are tightly bonded by ap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com