Microfluid self-conduction wound monitoring type intelligent dressing and preparation method thereof

A microfluidic and wound technology, applied in dressings, viscous dressings, medical science, etc., can solve the problems of monitoring response continuity and low sensitivity, exudate interference monitoring, blocking continuous monitoring, etc., to avoid the influence of dressing environmental factors , improve sensitivity and avoid serious infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

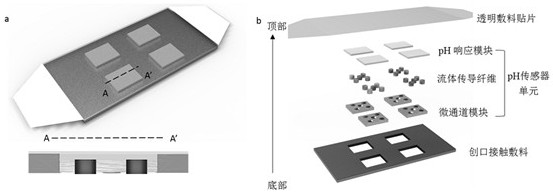

[0042] The present invention also provides a preparation method of the smart dressing described in the above scheme, comprising the following steps:

[0043] a) After mixing and degassing the silica gel solution, pour it into a microchannel mold to complete vulcanization, and take out to obtain silica gel with microchannels; cut the silica gel into a fixed size and thickness, keep the microchannel at the central position, and obtain a microchannel module;

[0044] b) Embedding fluid conduction fibers into the microchannels of the module obtained in step a) to obtain a conduction module with microfluid conduction; cutting out holes in the wound contact dressing, and embedding the conduction modules into the holes to obtain Wound contact dressing with fluid conduction function; the pH response module is fixed on the transparent dressing patch, and then covered with the wound contact dressing with fluid conduction function to obtain an intelligent dressing.

[0045] In the invent...

Embodiment 1

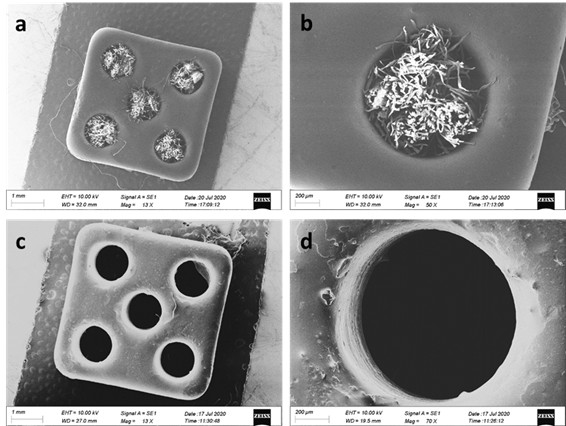

[0055] (1) Weigh 10g of liquid silica gel A and B components with Shore A hardness of 15HA, mix and stir evenly, place in a vacuum drying oven for degassing at negative pressure -0.1Mpa for 5min, and inject the degassed silica gel solution into the channel The number is 5, and the channel diameter is 1 mm in the forming mold, placed in an oven at a temperature of 80 ° C, and taken out after a curing time of 1.8 hours to obtain silica gel with micro channels.

[0056] (2) Cut the silica gel with microchannels obtained in step (1) to a cross-sectional area of 4mm*4mm and a thickness of 2mm to obtain a microchannel module.

[0057] (3) Embedding four multi-strand cotton fibers with a diameter of 200 μm into the channel of the microchannel module obtained in step (2), cutting the fibers to have the same length as the channel, and obtaining a conduction module with microfluidic conduction.

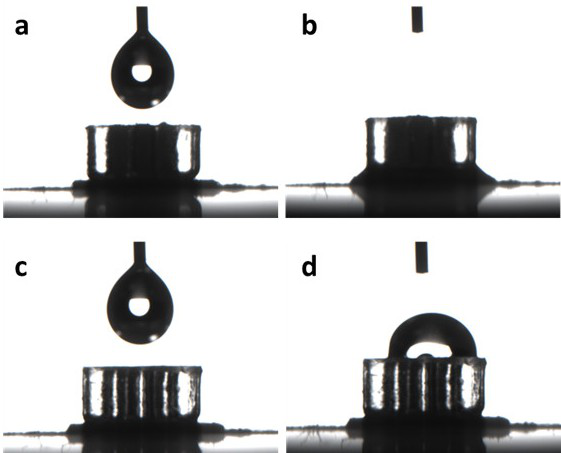

[0058] (4) Cut out a hole with a size of 3mm*3mm on the alginate dressing (wound contact ...

Embodiment 2

[0063] (1) Weigh 10g of liquid silica gel A and B components with Shore A hardness of 35HA, mix and stir evenly, place in a vacuum drying oven for degassing at negative pressure -0.1Mpa for 3min, and inject the degassed silica gel solution into the channel The number is 1, and the channel diameter is 1 mm in a forming mold, placed in an oven at a temperature of 80 ° C, and taken out after a curing time of 1.8 hours to obtain silica gel with micro channels.

[0064] (2) Cut the silica gel with microchannels obtained in step (1) to a cross-sectional area of 4mm*4mm and a thickness of 2mm to obtain a microchannel module.

[0065] (3) Embedding four multi-strand cotton fibers with a diameter of 200 μm into the channel of the microchannel module obtained in step (2), cutting the fibers to have the same length as the channel, and obtaining a conduction module with microfluidic conduction.

[0066] (4) Cut out a hole with a size of 3mm*3mm on the alginate dressing (wound contact dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com