PRO gas steel cylinder surface colored paint spraying process

A surface spraying and color painting technology, applied in the field of gas cylinders, can solve problems such as overall shedding, and achieve the effects of enhancing adhesion, overcoming large-area overall shedding, and improving paint firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

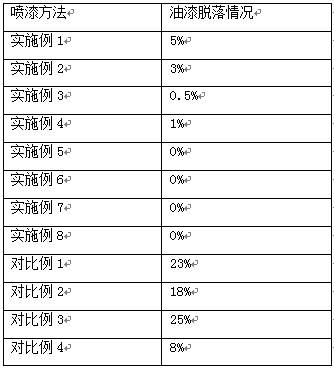

Examples

Embodiment 1

[0028] A PRO gas cylinder surface color paint spraying process, comprising the following steps:

[0029] (1) Clean the surface of the PRO gas cylinder and then dry it; if it is a newly produced gas cylinder, it can be washed directly with clean water; if it is a used gas cylinder, especially the gas cylinder used to hold liquefied petroleum gas, It needs to be soaked and cleaned with caustic lye, and then rinsed with water; the drying temperature is not limited, depending on the drying equipment, it can also be dried naturally.

[0030] (2) Spray the bottom liquid on the surface of the dried PRO gas cylinder, and the temperature of the bottom liquid is controlled at 30°C to 32°C; the bottom liquid is a water-based polyurethane resin solution, which is a commercially available product; the spraying amount of the bottom liquid is controlled at 80g / m 2 ;

[0031] (3) Before the bottom liquid is dried, spray 150 g / m of calcium carbonate powder with a particle size of 0.015mm to...

Embodiment 2

[0034] A PRO gas cylinder surface color paint spraying process, comprising the following steps:

[0035] (1) Use clean water to clean the surface of the PRO gas cylinder and then dry it;

[0036] (2) Spray the bottom liquid on the surface of the dried PRO gas cylinder, and the temperature of the bottom liquid is controlled at 35°C to 40°C; the bottom liquid is a water-based polyurethane resin solution, which is a commercially available product; the spraying amount of the bottom liquid is controlled at 110g / m 2 ;

[0037] (3) Before the bottom liquid is dried, spray 200g / m of calcium carbonate powder with a particle size of 0.015mm to 0.025mm on the bottom liquid 2 ;Spray powder immediately after spraying primer;

[0038] (4) After spraying the powder, spray the corresponding color paint.

Embodiment 3

[0040] A PRO gas cylinder surface color paint spraying process, comprising the following steps:

[0041] (1) Use lye (caustic soda solution) to clean the surface of the PRO gas cylinder and then dry it;

[0042] (2) Spray the bottom liquid on the surface of the dried PRO gas cylinder, and the temperature of the bottom liquid is controlled at 40°C to 45°C; the bottom liquid is a water-based polyurethane resin solution, using a commercially available product; the spraying amount of the bottom liquid is controlled at 100g / m 2 ;

[0043] (3) Before the bottom liquid is dried, spray 220g / m of calcium carbonate powder with a particle size of 0.025mm to 0.030mm on the bottom liquid 2 ;Spray powder immediately after spraying primer;

[0044] (4) Spray the corresponding color paint for the first time after powder spraying;

[0045] (5) Spray calcium carbonate powder with a particle size of 0.015mm to 0.020mm on the painted paint again, and also spray powder before the painted pain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com