Compact machining and assembling device

An assembly device, a compact technology, applied in electromechanical devices, metal processing, metal processing equipment, etc., can solve the problems of insufficient rigidity of the mechanical arm and large space occupied by the body, so as to achieve a compact device structure, improve machining accuracy or assembly accuracy , the effect of improving the lateral bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to detail the technical content, structural features, achieved goals and effects of the present invention, the following will be described in detail in conjunction with the accompanying drawings.

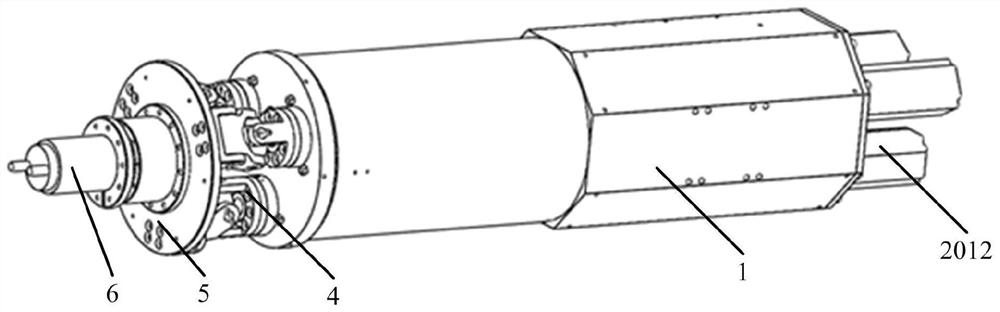

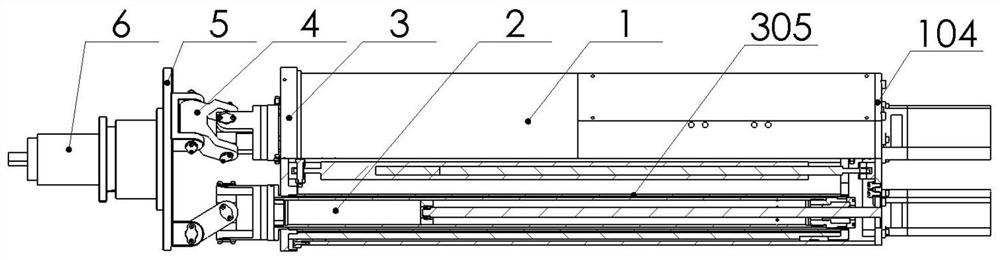

[0031] The invention provides a compact processing and assembling device, such as figure 1 with figure 2 As shown, it includes a cylinder housing 1 , a plurality of drive output branches 2 , an intermediate sliding cylinder 3 , a cross-axis steering member 4 , a motion platform 5 and an end effector 6 .

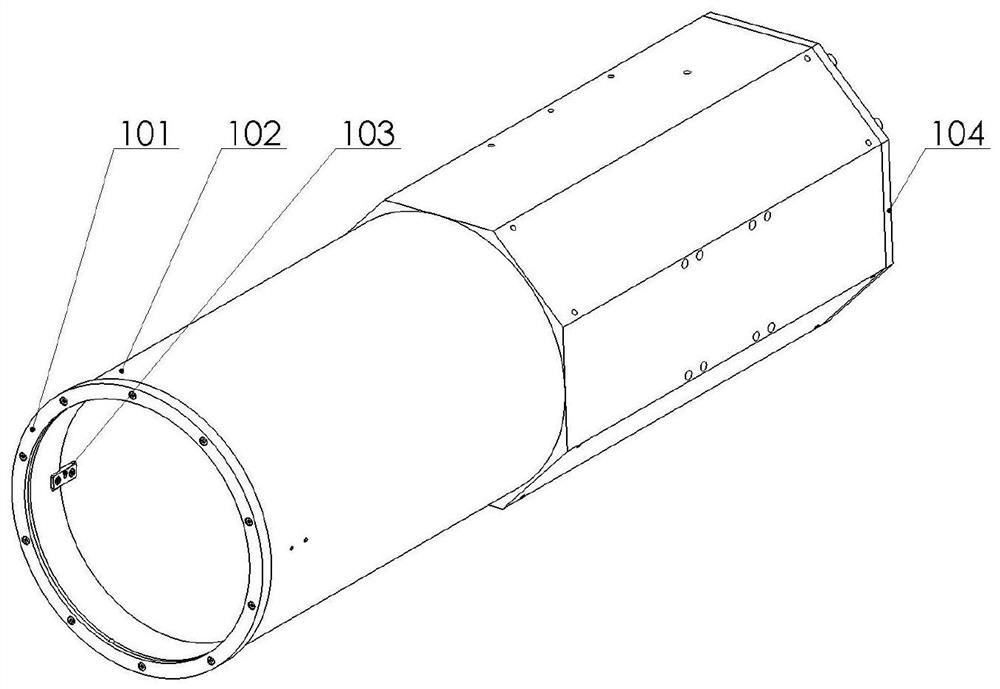

[0032] Such as image 3 As shown, the cylinder housing 1 includes a front end copper sleeve 101, a cylinder body 102 and a rear end mounting plate 104, the front end copper sleeve 101 is arranged at the first end of the cylinder body 102, and the inner wall of the cylinder body 102 first end is symmetrically provided with The guide block 103 and the rear mounting plate 104 are disposed on the second end of the cylinder body 102 .

[0033] Such as Figure 4 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com