Full-automatic packaging equipment for batteries and using method of full-automatic packaging equipment

A fully automatic packaging and battery technology, used in packaging, packaging machines, transportation and packaging, etc., can solve the problems of inclined battery packaging, unqualified packaging, hidden safety hazards, etc., to improve packaging efficiency and high installation safety. , to prevent the effect of short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings in the embodiments of the present invention;

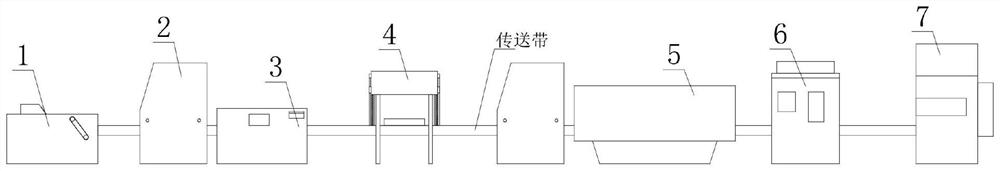

[0046] see Figure 1~5 , in the present invention, a fully automatic packaging equipment for batteries, including a plate unloading machine 1, a hoist 2, a motor inspection machine 3, an insulating ring upper machine 4, a labeling machine 5, a packaging machine 6 and a plate loading machine 7, A conveyor belt is set between two adjacent devices;

[0047] Unloading machine 1, used for loading batteries;

[0048] The hoist 2 is used to transfer and improve the position of the battery, and cooperate with the inspection motor 3 and the labeling machine;

[0049] Inspection motor 3, used to detect the positive and negative poles of the battery, to ensure the normal production of the battery, and to remove the corresponding defective products;

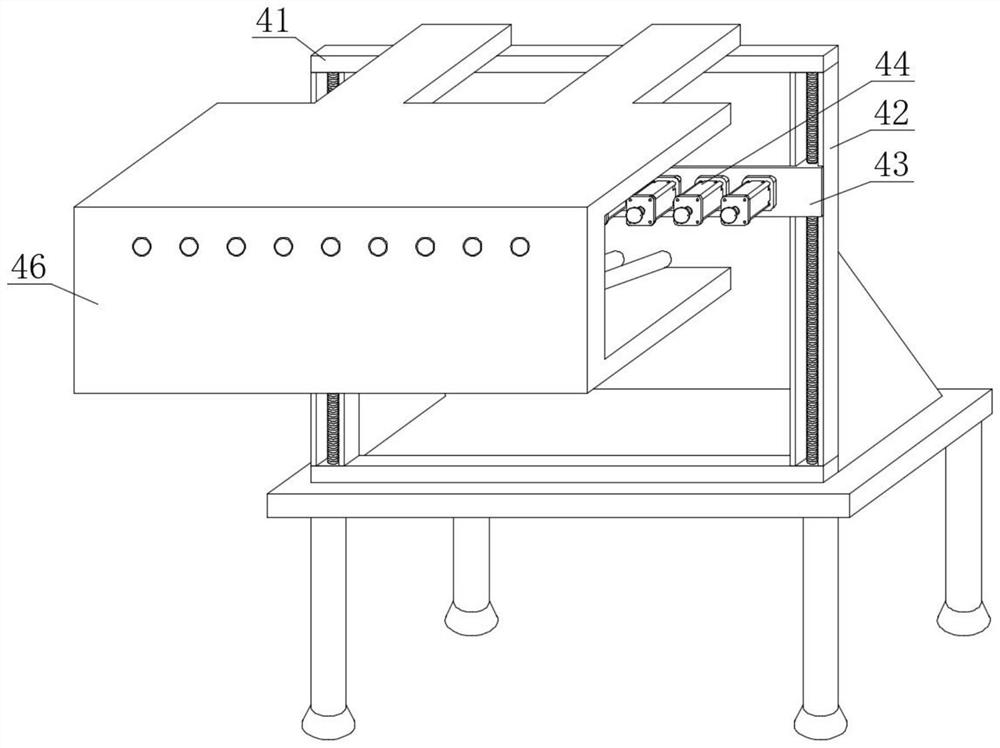

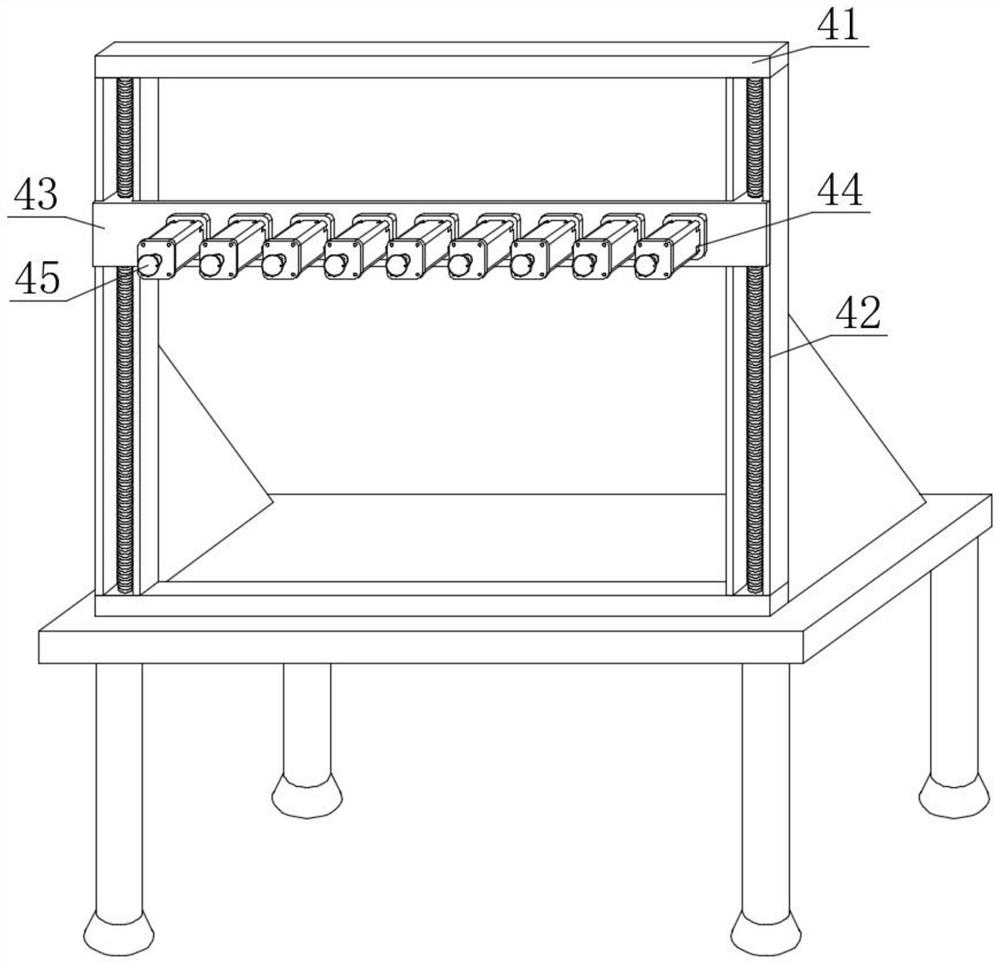

[0050] The upper in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com