Plasticized starch, bio-based plastic as well as raw material composition, preparation method and application of bio-based plastic

A technology of bio-based plastics and raw material compositions, which is applied in the fields of bio-based plastics and raw material compositions, and plasticized starch, can solve the problems of low utilization of papermaking waste, strong hydrophilic ability, slow degradation speed, etc. The effect of protection promotion, strong hydrophilic ability and compatibility improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] 1. Preparation of plasticized starch

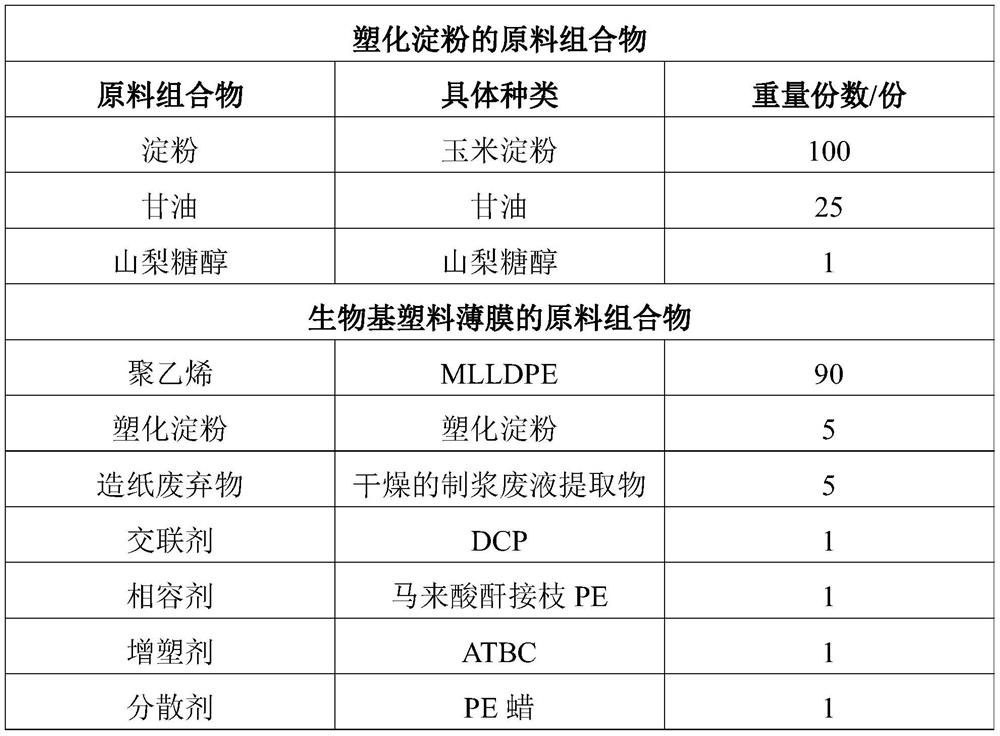

[0080] See Table 1 for the types and amounts of each component in the raw material composition of the plasticized starch.

[0081] Add the raw material composition of the plasticized starch into a high-speed blender and mix it at a temperature of 150°C, at a mixing speed of 300 rpm, and at a mixing time of 100 minutes to obtain the primary mixture 1;

[0082] Put the above-mentioned primary mixture 1 in a twin-screw extruder to extrude, plasticize, and granulate to obtain plasticized starch; the temperatures from the first zone to the sixth zone of the twin-screw extruder are 150°C, 155°C, and 170°C, respectively. °C, 175 °C, 180 °C and 185 °C; the head temperature of the twin-screw extruder is 175 °C, and the screw speed is 200 rpm.

[0083] 2. Preparation of bio-based plastic film

[0084] The types and amounts of each component in the raw material composition of the bio-based plastic film are shown in Table 1. Wherein, the pl...

Embodiment 2

[0091] 1. Preparation of plasticized starch

[0092] See Table 2 for the types and amounts of each component in the raw material composition of the plasticized starch.

[0093] The raw material composition of the plasticized starch was added into a high-speed blender and mixed, the mixing temperature was 50° C., the mixing speed was 200 rpm, and the mixing time was 60 minutes to obtain the primary mixture 1;

[0094] Put the above-mentioned primary mixture 1 in a twin-screw extruder to extrude, plasticize, and granulate to obtain plasticized starch. °C, 175 °C, 180 °C and 185 °C; the head temperature of the twin-screw extruder was 190 °C, and the screw speed was 200 rpm.

[0095] 2. Preparation of bio-based plastic film

[0096] The types and amounts of each component in the raw material composition of the bio-based plastic film are shown in Table 2. Wherein, the plasticized starch is the plasticized starch prepared in the above steps. The papermaking waste is obtained by ...

Embodiment 3

[0103] 1. Preparation of plasticized starch

[0104] See Table 3 for the types and amounts of each component in the raw material composition of the plasticized starch.

[0105] The raw material composition of the plasticized starch was added to a high-speed blender and mixed at a temperature of 130°C, at a speed of 300 rpm, and at a mixing time of 30 minutes to obtain the primary mixture 1;

[0106] Put the above-mentioned primary mixture 1 in a twin-screw extruder to extrude, plasticize, and granulate to obtain plasticized starch. °C, 175 °C, 180 °C and 195 °C; the head temperature of the twin-screw extruder was 200 °C, and the screw speed was 200 rpm.

[0107] 2. Preparation of bio-based plastic film

[0108] The types and amounts of each component in the raw material composition of the bio-based plastic film are shown in Table 3. Wherein, the plasticized starch is the plasticized starch prepared in the above steps. Papermaking waste is obtained from pulp after cleaning,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com