A gold-loaded porous submicron fiber and its preparation method

A sub-micron, fiber technology, applied in the field of gold-loaded porous sub-micron fibers and its preparation, can solve the problems of changing inherent properties, reducing the surface area of active sites, etc., achieving mild reaction conditions, increasing catalytic oxidation performance, and good formaldehyde removal ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

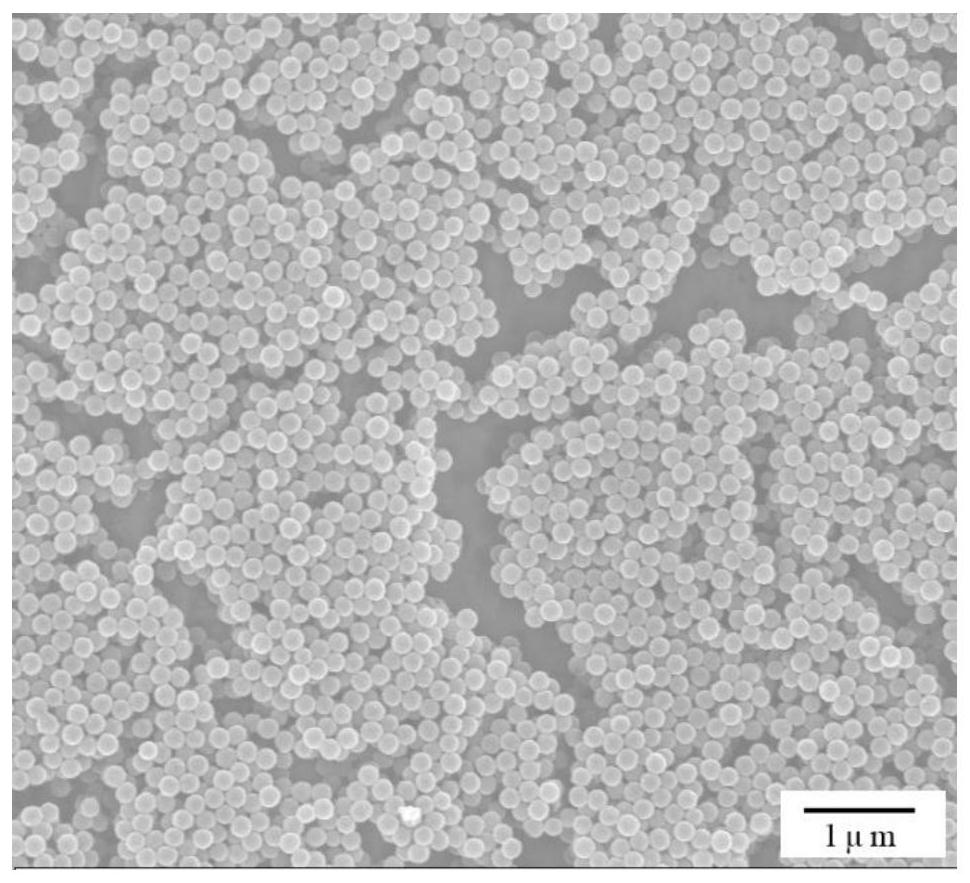

[0042] (1) Preparation of PMAA microspheres: Add 2ml of methacrylic acid (MAA) and 0.04g of azobisisobutyronitrile (AIBN) into a 100ml round bottom flask, pour 80ml of acetonitrile into it, and shake until completely mixed. Polymerization reaction occurred in the system by distillation precipitation polymerization method, control the boiling within 15min, continue heating until 40ml of solvent was distilled off, and then end the reaction, then cooled naturally to room temperature. The obtained product was repeatedly washed by centrifugation with acetonitrile for 4 times, and the product was stored in 30ml of acetonitrile to obtain monodisperse uncrosslinked polymer microspheres PMAA. The SEM image is shown in figure 1 .

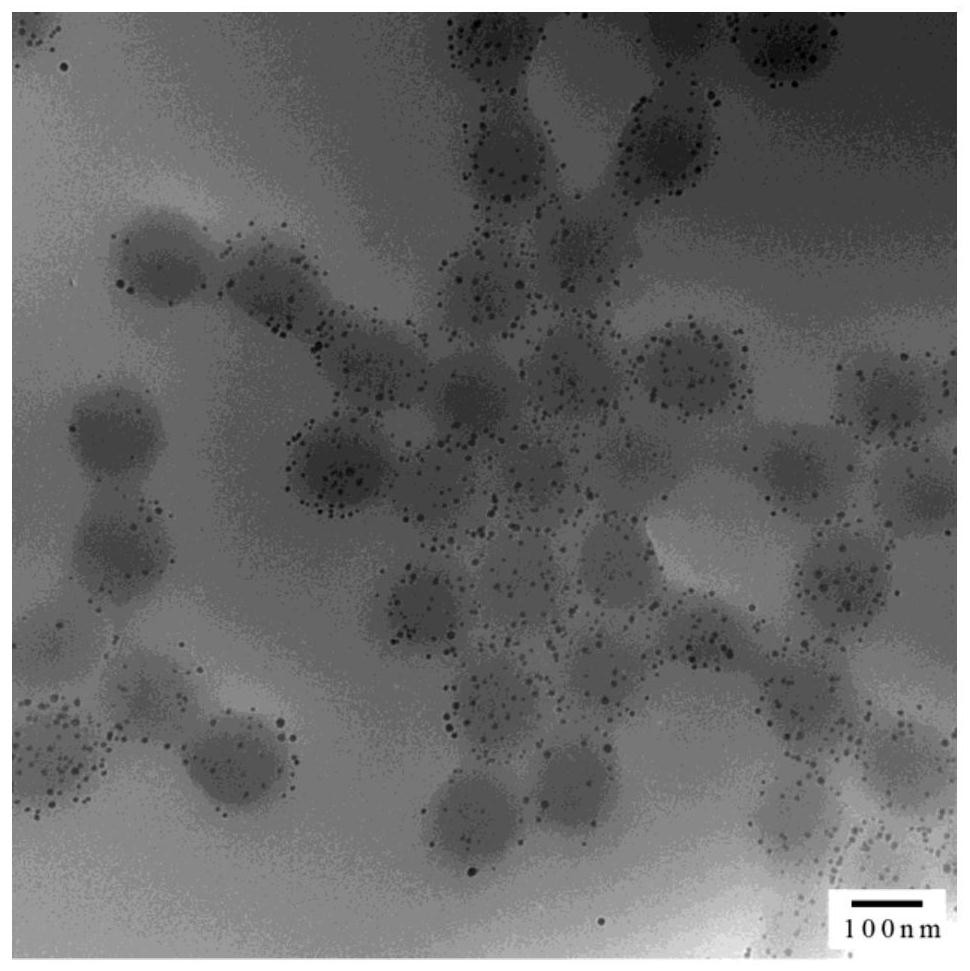

[0043] (2) Preparation of Au / PMAA composite microspheres: Take a 100ml round bottom flask, add 70ml of acetonitrile, add 3.2ml of PMAA and stir to mix, add 1ml of chloroauric acid solution, mix and stir at room temperature for 12h, take 0.0111g of Sodium bor...

Embodiment 2

[0045] (1) Preparation of PMAA microspheres: Add 2ml of methacrylic acid (MAA) and 0.04g of azobisisobutyronitrile (AIBN) into a 100ml round bottom flask, pour 80ml of acetonitrile into it, and shake until completely mixed. Polymerization reaction occurred in the system by distillation precipitation polymerization method, control the boiling within 15min, continue heating until 40ml of solvent was distilled off, and then end the reaction, then cooled naturally to room temperature. The resulting product was washed by centrifugation repeatedly with acetonitrile for 4 times, and the product was stored in 30 ml of acetonitrile to obtain monodisperse uncrosslinked polymer microspheres PMAA.

[0046] (2) Preparation of Au / PMAA composite microspheres: Take a 100ml round bottom flask, add 60ml of acetonitrile, add 3.2ml of PMAA and stir to mix, add 1ml of chloroauric acid solution, mix and stir at room temperature for 12h, take 0.0111g of Sodium borohydride was added to 0.3ml of ultra...

Embodiment 3

[0049] (1) Preparation of PMAA microspheres: Add 2ml of methacrylic acid (MAA) and 0.04g of azobisisobutyronitrile (AIBN) into a 100ml round bottom flask, pour 80ml of acetonitrile into it, and shake until completely mixed. Polymerization reaction occurred in the system by distillation precipitation polymerization method, control the boiling within 15min, continue heating until 40ml of solvent was distilled off, and then end the reaction, then cooled naturally to room temperature. The resulting product was washed by centrifugation repeatedly with acetonitrile for 4 times, and the product was stored in 30 ml of acetonitrile to obtain monodisperse uncrosslinked polymer microspheres PMAA.

[0050] (2) Preparation of Au / PMAA composite microspheres: take a 100ml round bottom flask, add 80ml of acetonitrile, add 3.2ml of PMAA and stir to mix, add 1ml of chloroauric acid solution, mix and stir at room temperature for 12h, take 0.0111g of Sodium borohydride was added to 0.3ml of ultra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com