Submicron fiber containing medicine-carrying nanometer balls and preparation method thereof

A drug-loaded nano- and sub-micron technology, which can be applied to non-active ingredients in medical preparations, pharmaceutical formulations, and chemical characteristics of fibers, etc. It can achieve the effect of good slow release effect, novel structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

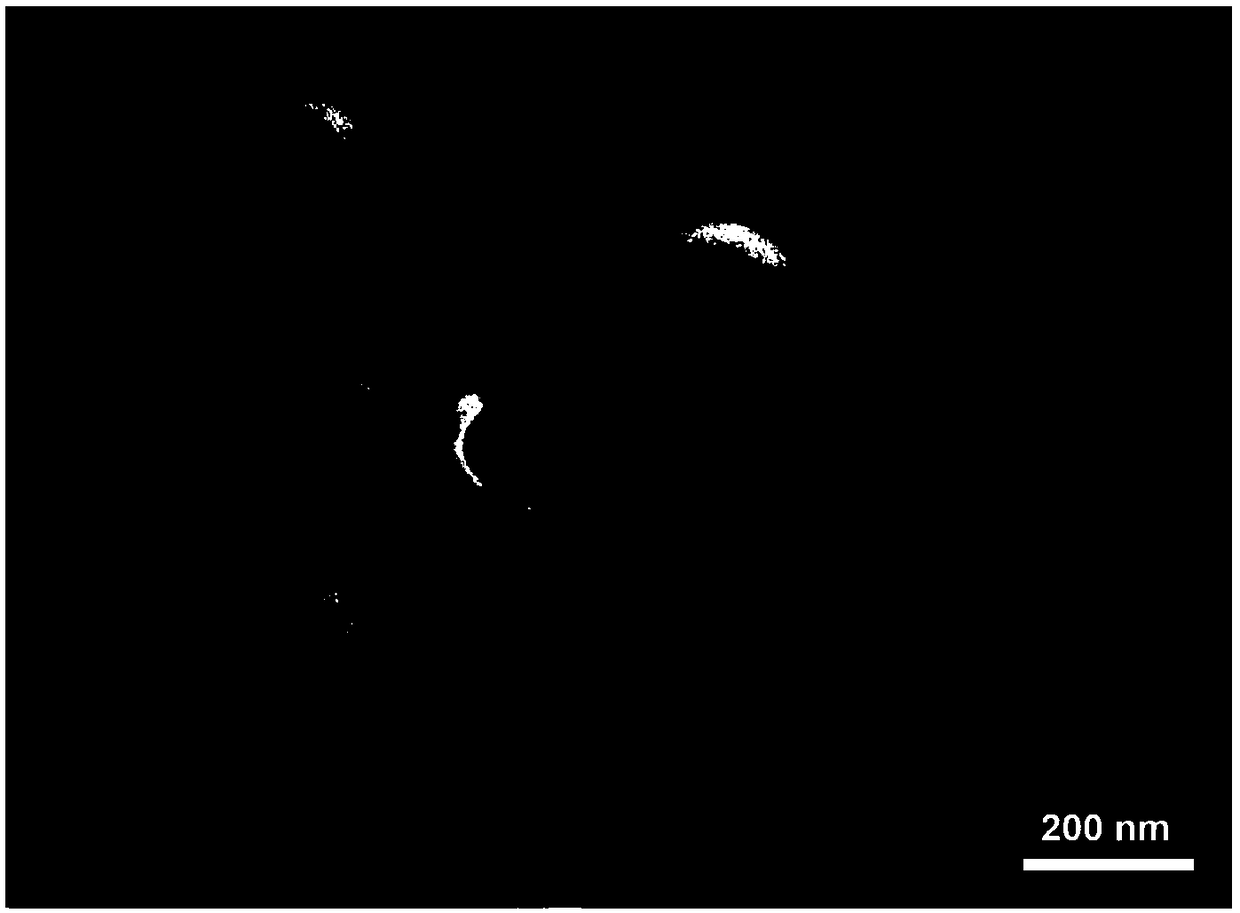

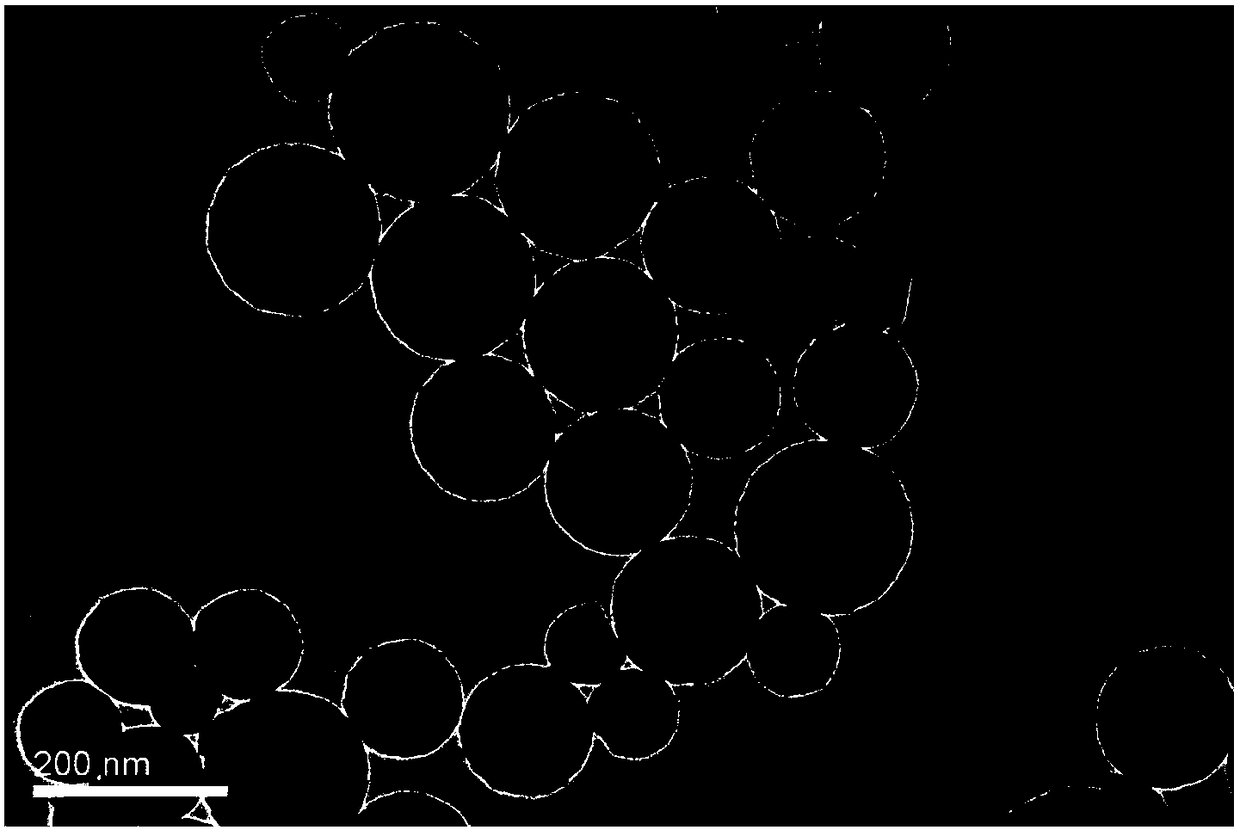

[0031] (1) Hollow mesoporous SiO 2 Preparation: Add 4.3ml ammonia water to 0.15g polyacrylic acid aqueous solution, stir well, add 87ml absolute ethanol, stir at room temperature for 1h, add 1.4ml ethyl orthosilicate dropwise, continue to seal and stir at room temperature for 12h. The resulting solution was centrifuged and cleaned 5 times, placed in an oven at 50°C and dried to obtain hollow mesoporous silica, which was dispersed in an ethanol solution and placed on a silicon wafer and a carbon film for field emission and transmission. The test results are as follows figure 1 with figure 2 As shown, it can be seen that the shape of the nanoparticles is relatively regular, the size is not uniform, and there is an obvious hollow mesoporous structure.

[0032] (2) SiO loaded with triclosan 2 Preparation of nanoparticles: Disperse 1.6 g of triclosan in 60 ml of absolute ethanol, and stir at room temperature for 1 hour to completely dissolve triclosan. Weigh 0.8g of hollow mesoporou...

Embodiment 2

[0038] (1) Hollow mesoporous SiO 2 Preparation: Add 4.5ml of ammonia to 0.17g of polyacrylic acid aqueous solution. After stirring, add 88ml of absolute ethanol. After stirring for 1h at room temperature, add 1.7ml of ethyl orthosilicate dropwise and continue to seal and stir at room temperature for 12h. The resulting solution was centrifuged and cleaned 5 times, placed in an oven at 50°C and dried to obtain hollow mesoporous silica, which was dispersed in an ethanol solution and placed on a silicon wafer and a carbon film for field emission and transmission. The test results are as follows figure 1 with figure 2 As shown, it can be seen that the shape of the nanoparticles is relatively regular, the size is not uniform, and there is an obvious hollow mesoporous structure.

[0039] (2) SiO loaded with triclosan 2 Preparation of nanoparticles: Disperse 1.6 g of triclosan in 60 ml of absolute ethanol, and stir at room temperature for 1 hour to completely dissolve triclosan. Weigh ...

Embodiment 3

[0045] (1) Hollow mesoporous SiO 2 Preparation: Add 4.5ml of ammonia to 0.18g of polyacrylic acid aqueous solution. After stirring, add 90ml of absolute ethanol. After stirring for 1h at room temperature, add 1.5ml of ethyl orthosilicate dropwise, and continue to seal and stir at room temperature for 12h. The resulting solution was centrifuged and cleaned 5 times, placed in an oven at 50°C and dried to obtain hollow mesoporous silica, which was dispersed in an ethanol solution and placed on a silicon wafer and a carbon film for field emission and transmission. The test results are as follows figure 1 with figure 2 As shown, it can be seen that the shape of the nanoparticles is relatively regular, the size is not uniform, and there is an obvious hollow mesoporous structure.

[0046] (2) SiO loaded with triclosan 2 Preparation of nanoparticles: Disperse 1.6 g of triclosan in 60 ml of absolute ethanol, and stir at room temperature for 1 hour to completely dissolve triclosan. Weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com