Plant cell sap extraction device and method

A plant cell and extraction device technology, applied in biochemical cleaning devices, biochemical equipment and methods, enzymology/microbiology devices, etc., can solve the problems of decomposition of typical substances, low content of target compounds, decomposition, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

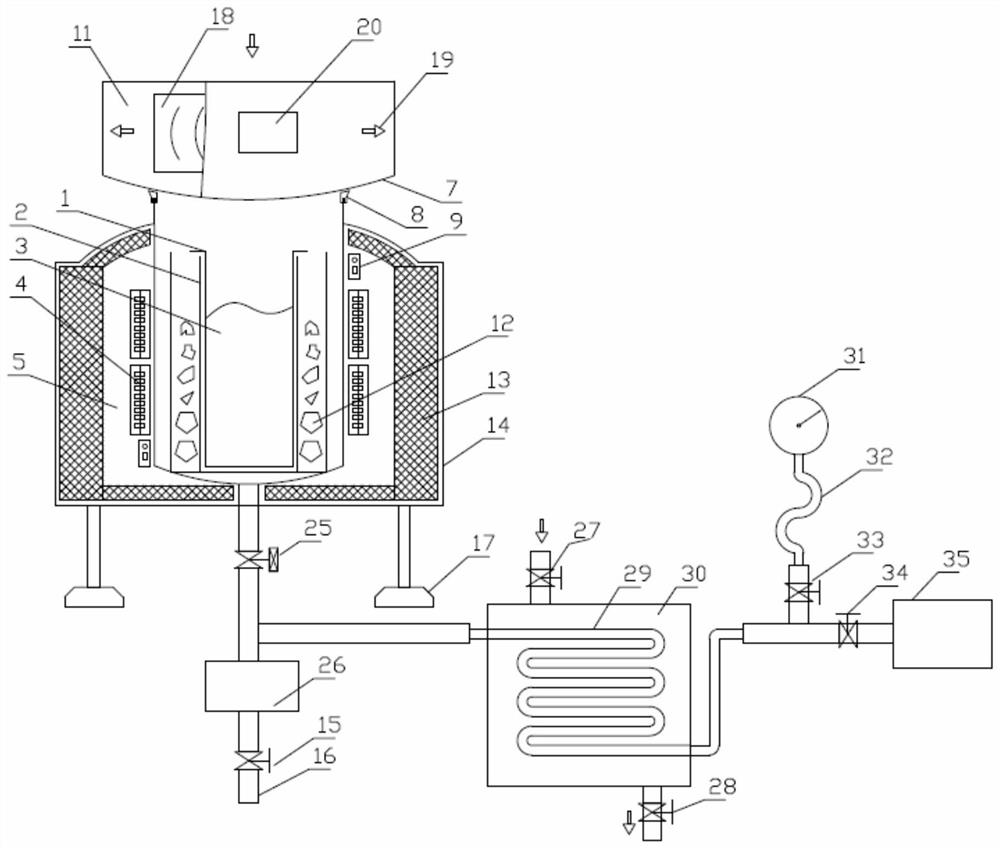

Embodiment 1

[0031] The present invention prepares cell fluid through the following steps: S1) soaking at room temperature for 3 to 5 hours until the dried extract is swollen and saturated with water; 120°C~190°C, absolute pressure 130KPa~320KPa, to break the plant cell wall and vaporize the cell fluid;

[0032] S2) Separation of heavy metals and drug residues under high temperature and negative pressure: Cool the top part of the container by air cooling or water cooling to keep the internal pressure of the container at the ultimate vacuum of 40KPa~60KPa, and control the internal temperature of the container to 120°C~190°C. The liquid forms droplets on the top wall of the container and is separated from carbon-containing heavy metal impurities and drug residues, and the separated waste liquid is collected and discharged through the waste liquid tank;

[0033] S3) Extraction of high-temperature negative pressure cell fluid: start the vacuum pump to reduce the pressure of the container to th...

Embodiment 2

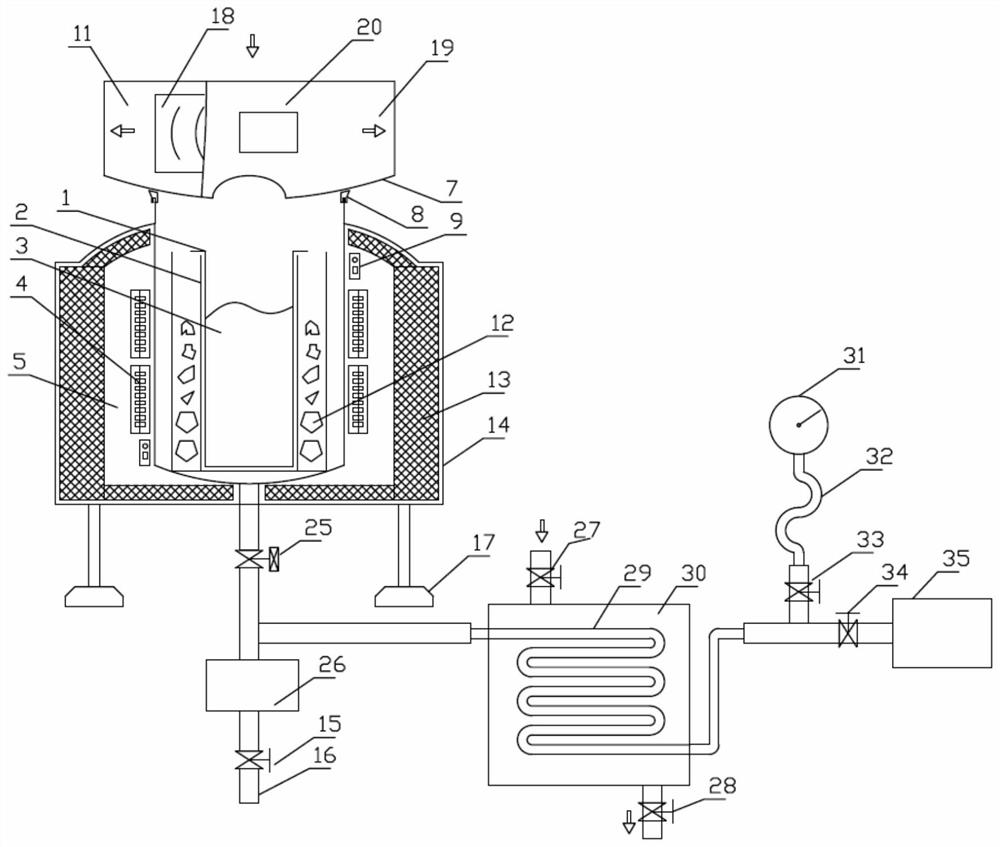

[0041] see figure 2 , this embodiment is further improved on the basis of Embodiment 1, specifically, the bottom wall 7 of the cover body includes a central area and an outer ring area, the outer ring area arches downward toward the central area, and the central area Then the upward arc is arched to form an arched circle structure, and the contour line connecting the outer ring area and the central area is positively projected in the container. This structure can also make the cell fluid attached to the surface of the bottom wall slide to the outside along the arc surface. The junction of the ring area and the center area, then drips into the container. The rest of the structure of this embodiment is the same as that of Embodiment 1.

Embodiment 3

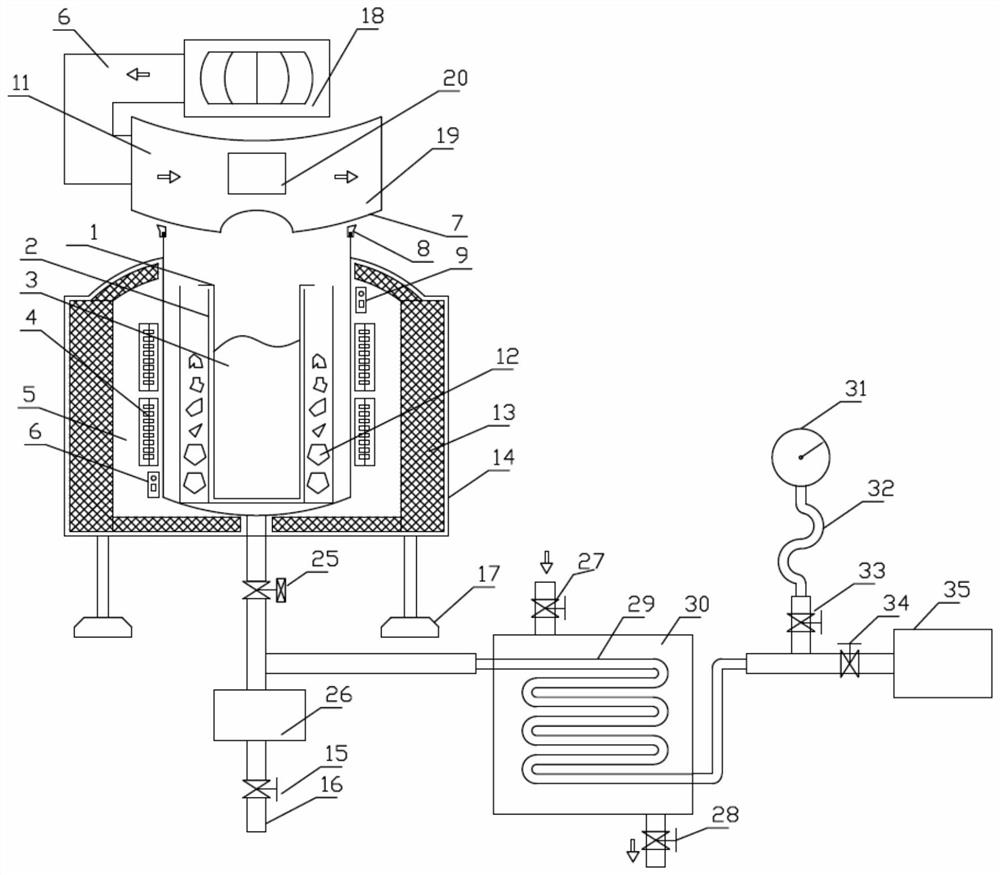

[0043] see image 3 , this embodiment is further improved on the basis of Embodiment 2, specifically, the cooling fan 18 is placed outside, the air inlet and outlet of the cooling air chamber 11 are respectively opened on the side wall of the cover body, and the air inlet of the cooling air chamber passes through The external air duct 6 is connected to the air outlet of the cooling fan 18 . The rest of the structure of this embodiment is the same as that of the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com