1180MPa-grade high-plasticity high-hole-expansion steel and manufacturing method thereof

A manufacturing method and high plasticity technology, applied in the field of high-strength steel, can solve problems such as batch use, and achieve the effect of excellent hole expansion performance and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

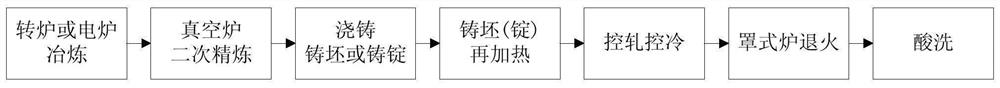

[0057] see Figure 1 ~ Figure 4 , the manufacture method of 1180MPa grade high plasticity high hole expansion steel of the present invention, it comprises the steps:

[0058] 1) Smelting and casting

[0059] Smelting in a converter or an electric furnace according to the stated composition, followed by secondary refining in a vacuum furnace and casting into billets or ingots;

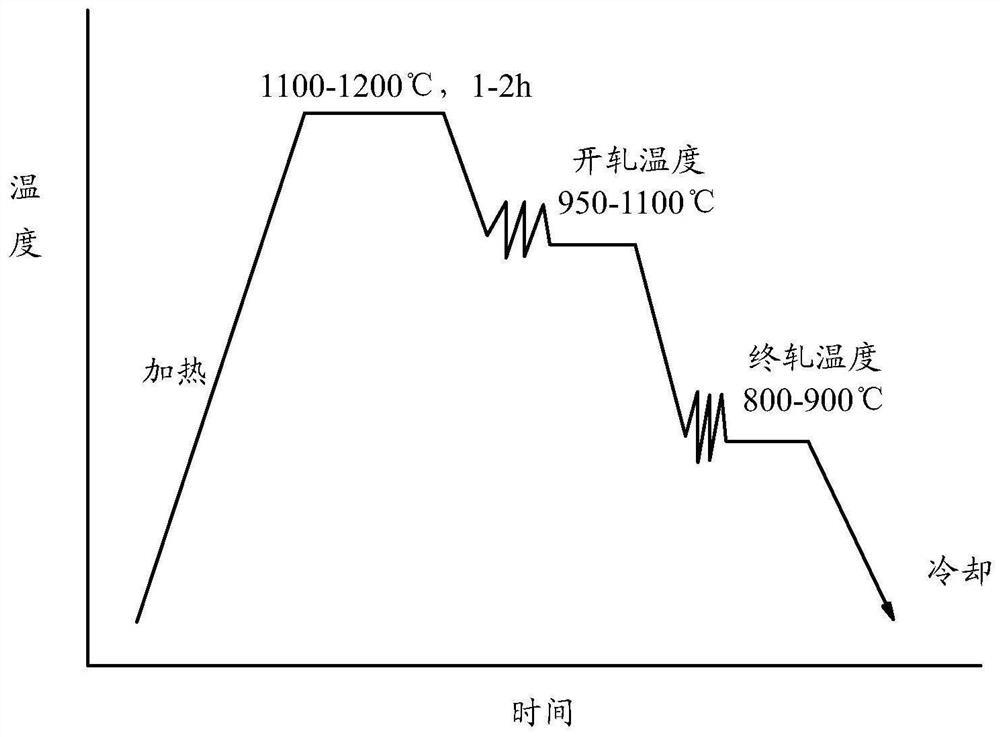

[0060] 2) Reheating of billet or ingot, heating temperature: 1100-1200°C, holding time: 1-2 hours;

[0061] 3) hot rolling

[0062] Rolling start temperature: 950-1100°C, 3-5 passes of high pressure above 950°C and cumulative deformation ≥ 50%, then the intermediate billet is heated to 900-950°C, and then rolled for 3-7 passes And cumulative deformation ≥ 70%; final rolling temperature 800 ~ 900 ℃;

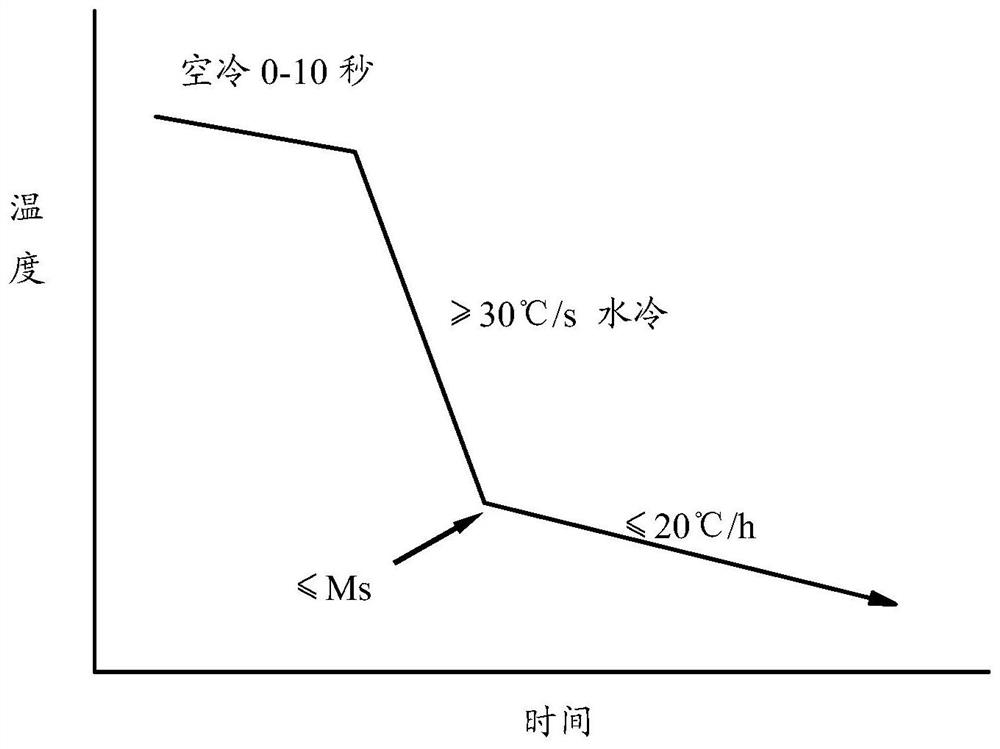

[0063] 4) cooling

[0064] First perform air cooling for 0-10 seconds, then water-cool the steel plate to a temperature below the Ms point at a cooling rate of ≥30°C / s, and slowly cool to room temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com