Strip steel alkali washing section foam co-processing device and method

A technology of co-processing and defoaming device, applied in chemical instruments and methods, separation methods, foam dispersion/prevention, etc., can solve the problems of reduced cleaning efficiency, high foam strength, polluted lye, etc., and achieves low investment and low pollution. , the effect of reducing churn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

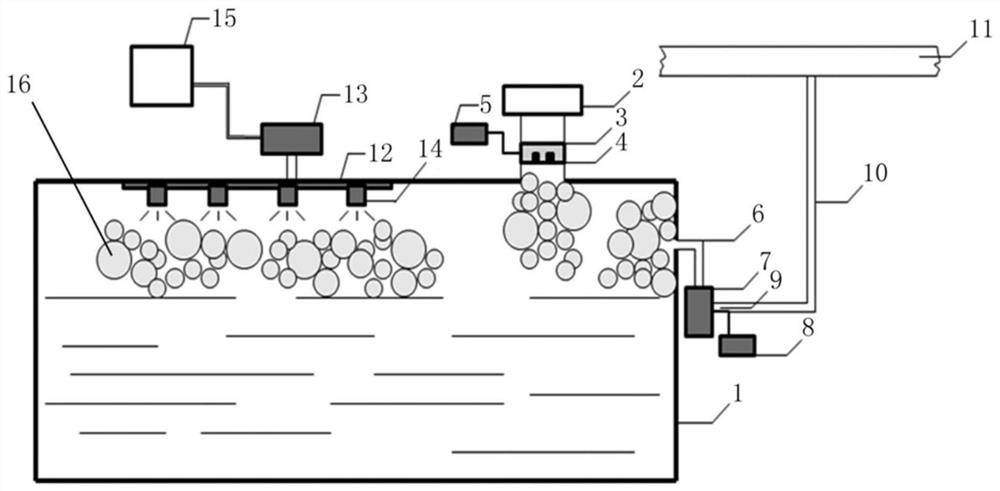

[0025] A foam synergistic treatment device in the strip alkali washing section, such as figure 1 As shown, it includes a lye circulation tank 1, the top of the lye circulation tank 1 is provided with a backflow port 2 and a steam coil inspection flange 12, and the side of the lye circulation tank 1 is provided with an overflow port 6.

[0026] The return port 2 is provided with an ultrasonic defoaming device and a return filter 3, the ultrasonic defoaming device is composed of an ultrasonic vibrator 4 and a generator control cabinet 5, and the generator control cabinet 5 communicates with the ultrasonic vibrator through a cable 4 is connected to and controls the operation of the ultrasonic vibrator 4, and the ultrasonic vibrator 4 is arranged on the side wall of the return filter 3.

[0027] The overflow port 6 is provided with an electric heating defoaming device, the electric heating defoaming device is composed of an electric heater 7, a temperature control box 8 and a valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com