Preparation method of hydrogel based on carbon nanotube composite molybdenum disulfide nanosheets

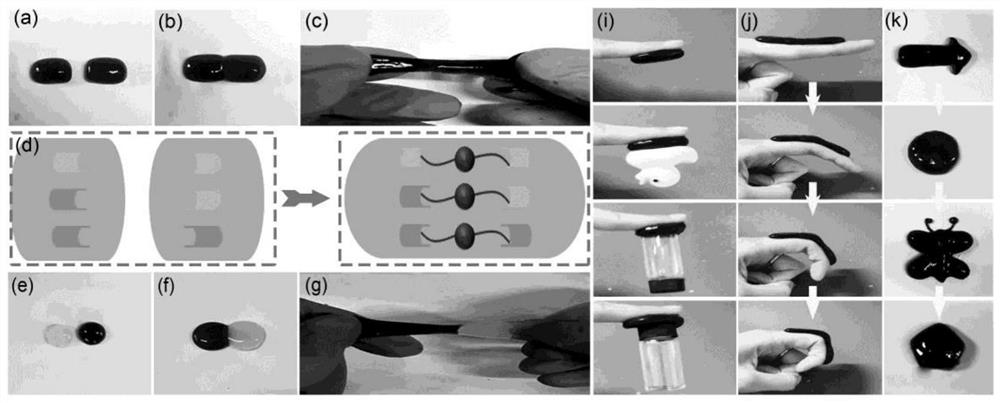

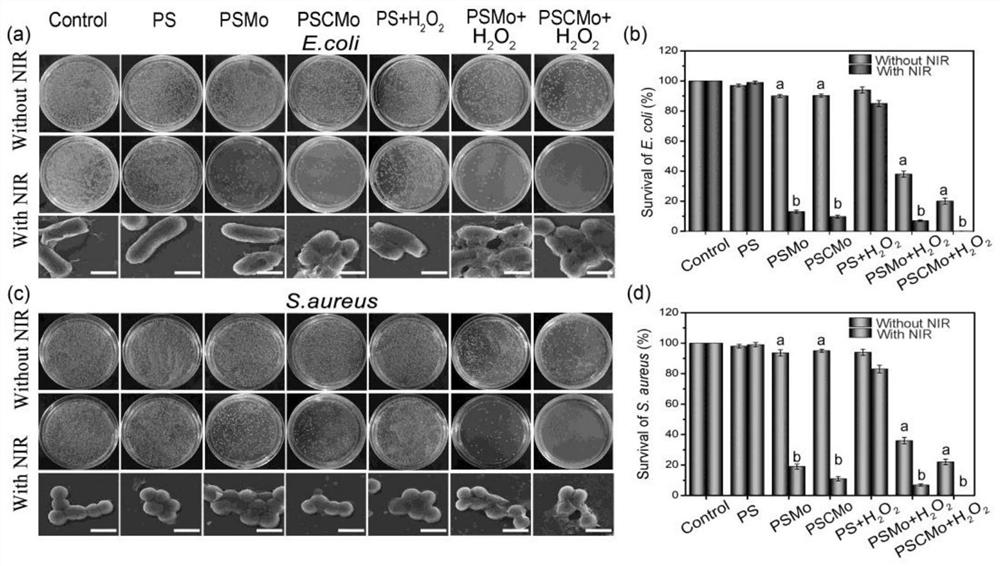

A carbon nanotube composite and molybdenum disulfide technology, applied in bandages, medical science, etc., can solve the problems of low oxygen content in wounds, unfavorable wound repair, etc., and achieve enhanced enzyme activity, good shape adaptability, and promotion of electron transfer. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

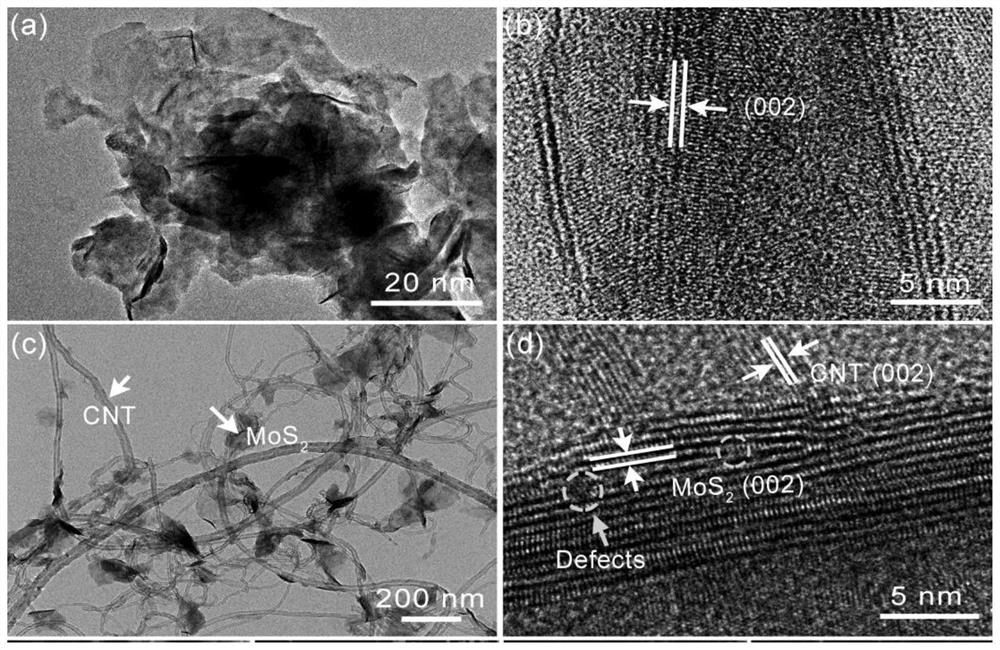

[0033] The present embodiment provides a method for preparing a hydrogel based on carbon nanotube composite molybdenum disulfide nanosheets, comprising the following steps:

[0034] Step 1, ultrasonically dispersing the carbon nanotubes in deionized water to obtain a dispersion liquid containing carbon nanotubes; the volume of the deionized water is 0.80 times the mass of the carbon nanotubes, the unit of the volume of the deionized water is mL, and the carbon nanotubes The unit of mass is mg; the ultrasonic frequency of the ultrasonic dispersion is 40KHz, the ultrasonic power is 600w; the time of the ultrasonic dispersion is 10min; the length of the carbon nanotube is 10μm, and the diameter is 10nm;

[0035] Step 2, dissolving sodium molybdate and thiourea in the carbon nanotube-containing dispersion described in step 1 to obtain system A; the quality of the sodium molybdate is 12.0 times the quality of the carbon nanotubes; the quality of the thiourea is 16.0 times the mass ...

Embodiment 2

[0059] The present embodiment provides a method for preparing a hydrogel based on carbon nanotube composite molybdenum disulfide nanosheets, comprising the following steps:

[0060] Step 1, ultrasonically dispersing the carbon nanotubes in deionized water to obtain a dispersion liquid containing carbon nanotubes; the volume of the deionized water is 0.40 times the mass of the carbon nanotubes, the unit of the volume of the deionized water is mL, and the carbon nanotubes The unit of mass is mg; the ultrasonic frequency of the ultrasonic dispersion is 40KHz, the ultrasonic power is 600w; the time of the ultrasonic dispersion is 30min; the length of the carbon nanotube is 30μm, and the diameter is 20nm;

[0061] Step 2, dissolving sodium molybdate and thiourea in the carbon nanotube-containing dispersion described in step 1 to obtain system A; the quality of the sodium molybdate is 6.5 times the quality of the carbon nanotubes; the quality of the thiourea is 8.1 times the mass of...

Embodiment 3

[0068] The present embodiment provides a method for preparing a hydrogel based on carbon nanotube composite molybdenum disulfide nanosheets, comprising the following steps:

[0069] Step 1, ultrasonically dispersing the carbon nanotubes in deionized water to obtain a dispersion liquid containing carbon nanotubes; the volume of the deionized water is 0.44 times the mass of the carbon nanotubes, the unit of the volume of the deionized water is mL, and the carbon nanotubes The unit of mass is mg; the ultrasonic frequency of the ultrasonic dispersion is 40KHz, the ultrasonic power is 600w; the time of the ultrasonic dispersion is 60min; the length of the carbon nanotube is 20μm, and the diameter is 15nm;

[0070] Step 2, dissolving sodium molybdate and thiourea in the carbon nanotube-containing dispersion described in step 1 to obtain system A; the quality of the sodium molybdate is 4.0 times the quality of the carbon nanotubes; the quality of the thiourea is 5.1 times the mass of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com