Densimeter and method for testing density of battery slurry

A density meter and battery technology, which is applied in the direction of material analysis by observing sunken objects, can solve the problems of inaccurate measurement of high-viscosity lithium battery slurry, hidden dangers of human body safety, cumbersome operation procedures, etc., and achieve fast measurement speed, Improved accuracy, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

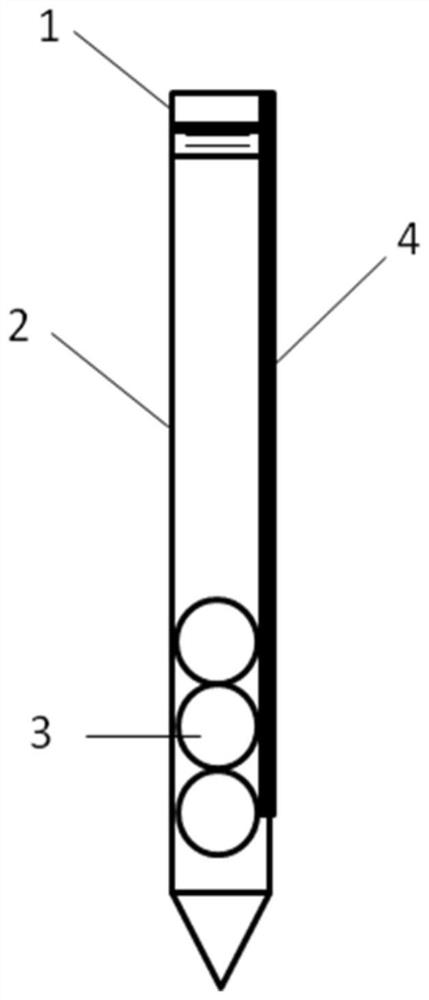

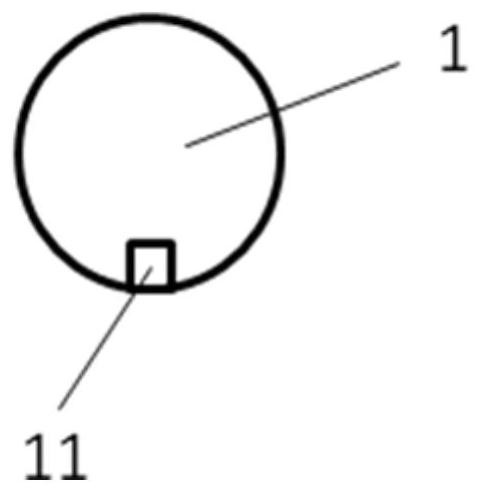

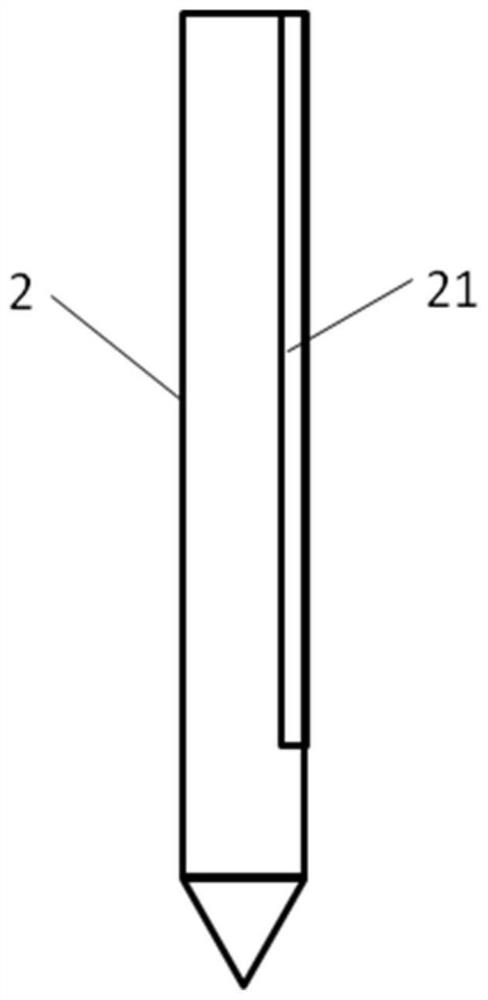

[0029] Such as Figure 1-Figure 3 As shown in , a density meter provided by an embodiment of the present invention includes: a top cover 1, a measuring tube 2, a counterweight 3, and a positioning bar 4, the upper end of the measuring tube 2 is provided with an opening, and the counterweight 3 is installed from the opening. Inlet tube 2, the bottom of the tube 2 is a cone structure, the top cover 1 is set on the upper end of the tube 2 to seal the opening, the side of the tube 2 is provided with a scale line, and the positioning strip 4 is set on the tube 2 with a scale line On one side, the top cover 1 is provided with a slot 11 , and the slot 11 runs through the top cover 1 .

[0030] The bottom of the measuring tube 2 is a cone. The design of the cone can reduce the resistance of the density meter when it enters t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com