Electrostatic force tuning type MEMS electric field sensor and detection method

An electric field sensor, electrostatic force technology, applied in the sensor field, can solve the problems of limited sensing area, low signal-to-noise ratio, insufficient anti-interference ability, etc., and achieve the effect of accurate and high-sensitivity measurement and high-sensitivity measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

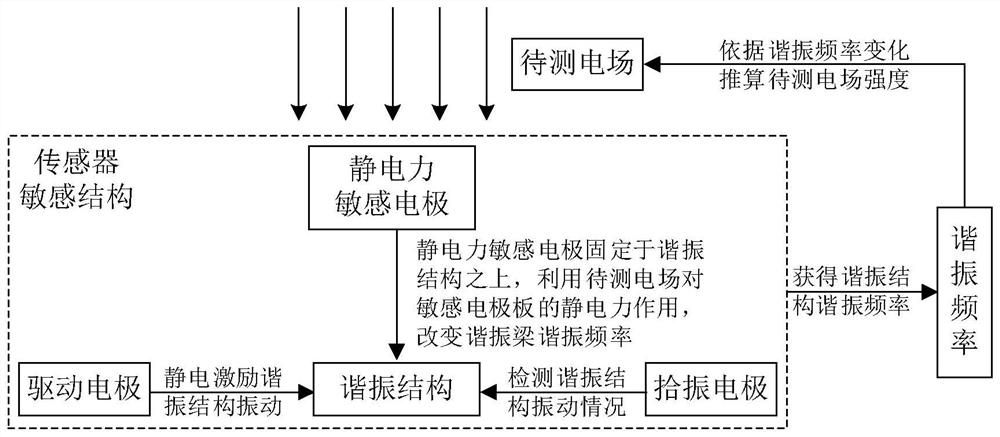

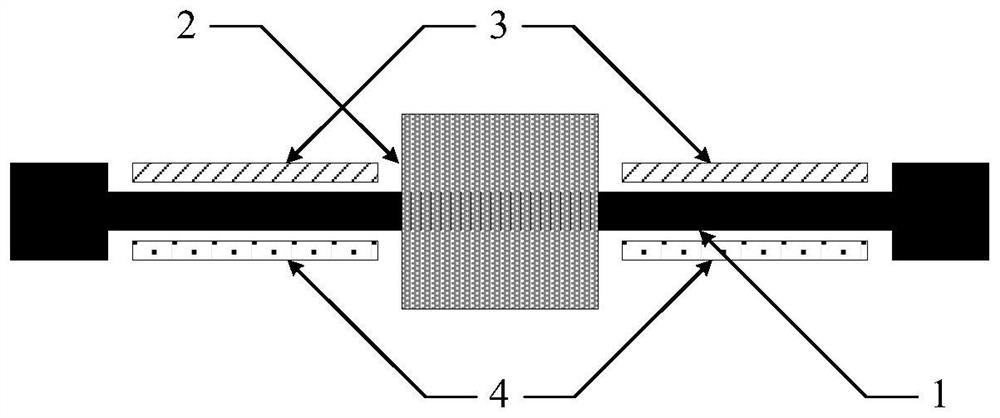

[0030] A kind of electrostatic force tuning type MEMS electric field sensor of the present application, such as figure 1 As shown, it includes driving electrodes, pickup electrodes, resonant structures, and electrostatic force sensitive electrodes. The electrostatic force sensitive electrodes are directly connected to the resonant structure. The potential of the electrostatic force sensitive electrodes and the resonant structure is the same, which is consistent with the zero potential of the sensor system. Under the direct or indirect effect of the electric field to be measured, the electrostatic force sensitive electrode is attracted by the electrostatic force, thereby changing the resonant frequency of the resonant structure, and realizing the measurement of the electric field to be measured by detecting the change of the resonant frequency.

[0031] The driving capacitance is formed between the driving electrode and the resonant structure, and the pickup capacitance is forme...

specific Embodiment 2

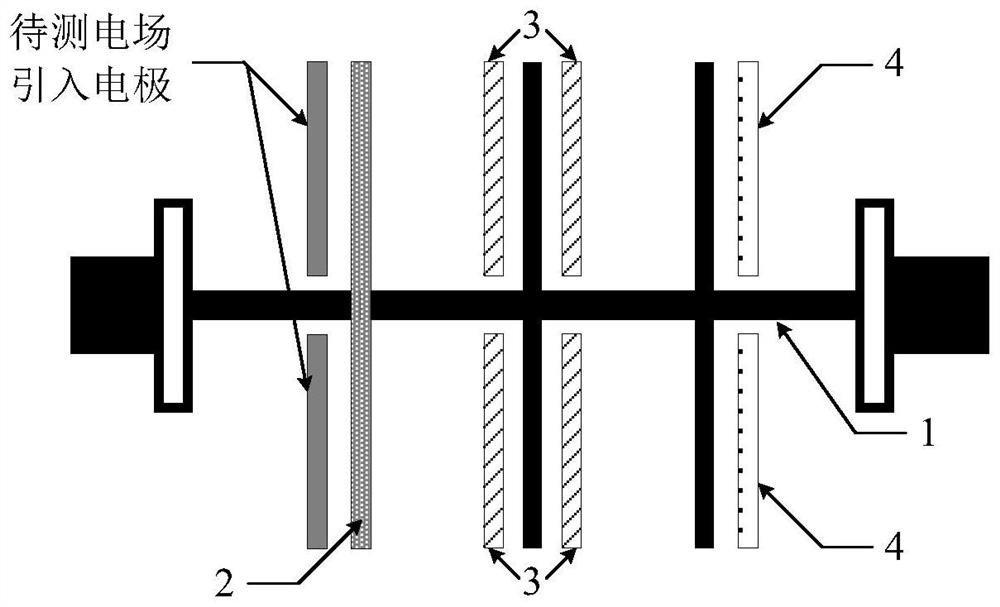

[0044] An electrostatic force tuning type MEMS electric field sensor of the present application includes a driving electrode, a vibration pickup electrode, a resonant structure, an electrostatic force sensitive electrode, an introduction electrode and an external electrode, the electrostatic force sensitive electrode is connected with the resonant structure, and the driving electrode is used for resonant The drive capacitance is formed between the structures, the pickup electrode is used to form a pickup capacitance with the resonant structure, the external electrode is connected to the lead-in electrode, and the lead-in capacitance is formed between the lead-in electrode and the electrostatic force sensitive electrode, and the external electrode is used to sense the electric field to be measured , and the electrostatic force of the electric field to be measured is transferred to the electrostatic force sensitive electrode through the introduction electrode, causing a change in ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap