Equipment for assembling iron core and silica gel particle of electromagnetic valve

A technology for assembling equipment and silica gel particles, which is applied to metal processing equipment, measuring devices, optical devices, etc., and can solve problems such as low production efficiency, more damage, and frequent material jams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

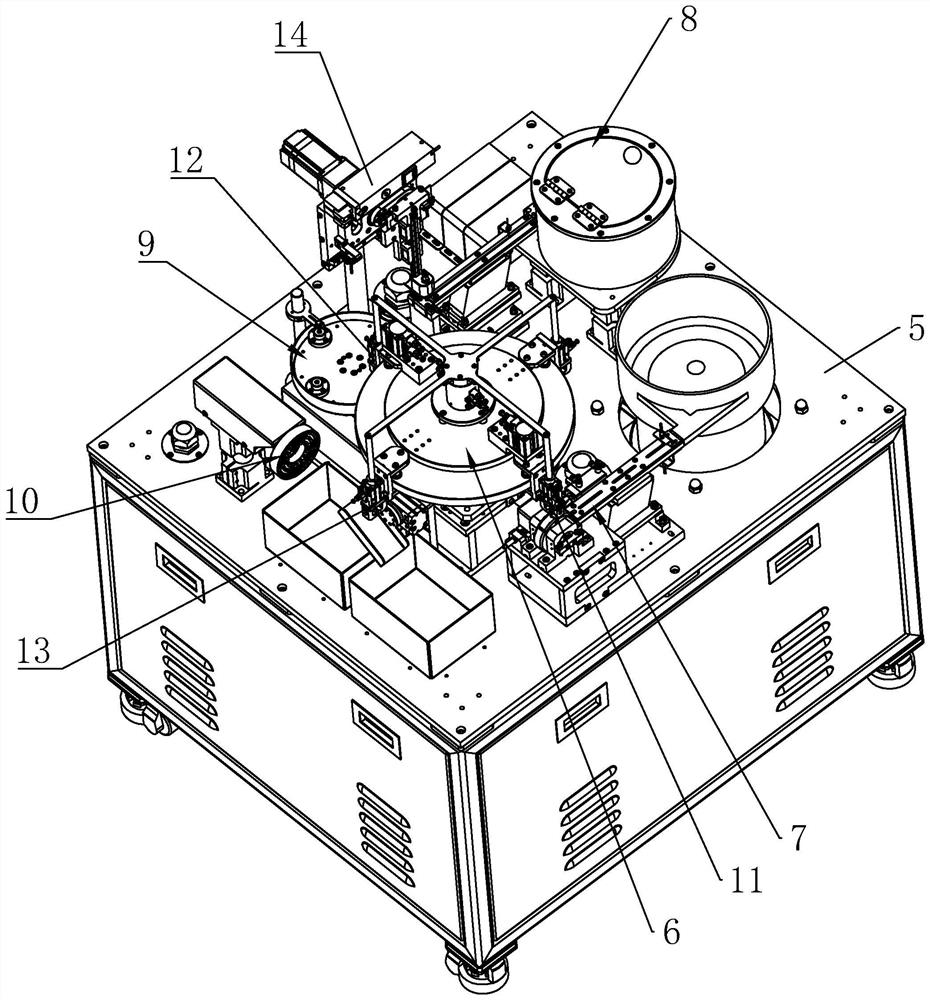

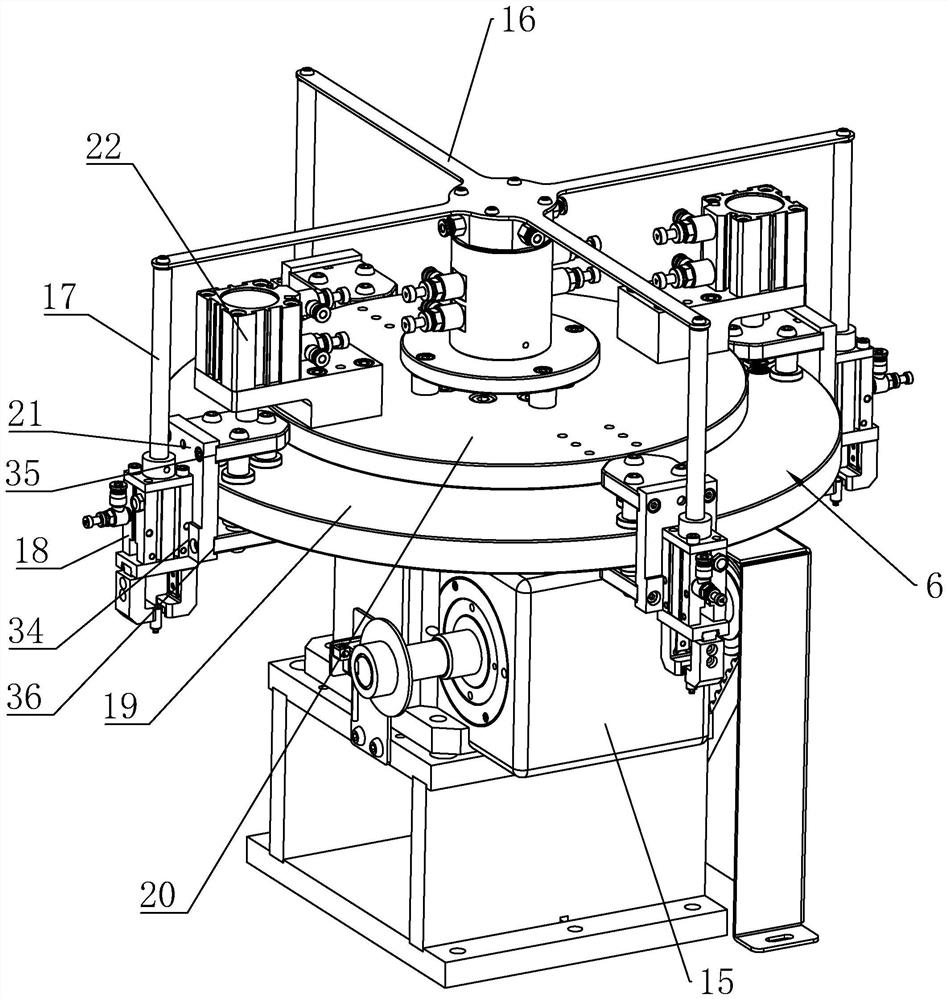

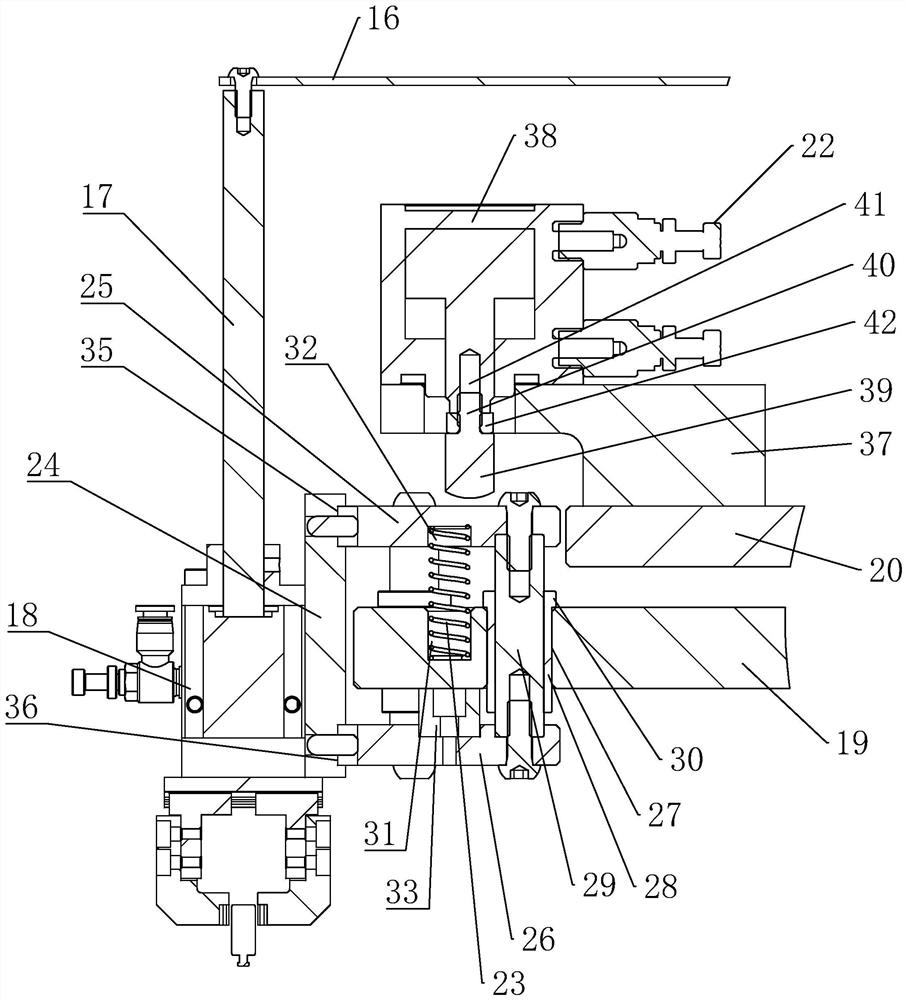

[0075] Example: as attached Figure 1-14 As shown in the assembly equipment of the iron core and silica gel particles of the solenoid valve, the iron core 1 is provided with a connecting convex part 2 with a T-shaped cross section, and the silica gel particle 3 is provided with a connecting convex part 2 corresponding to the connecting convex part 2. With the matching connection groove 4, the silica gel particle 3 is in the shape of a groove at one end and a solid end, and the solid end has a small diameter and a large weight (for the assembly structure of the iron core 1 and the silica gel particle 3, please refer to the attached Figure 14 ); the equipment includes a processing platform 5, which is provided with a material conveying mechanism 6, an iron core feeding mechanism 7, a silica gel particle feeding mechanism 8, a silica gel particle turntable 9, a CCD detection and a discharging mechanism 10, and processing On the platform 5, around the material conveying mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com