Aerogel composite coating and application thereof in underground oil pipe

A composite coating and airgel technology, which is applied to epoxy resin coatings, devices for coating liquid on the surface, coatings, etc., can solve the problems of airgel coatings that are easy to absorb moisture and crack when exposed to water, and achieve heat preservation effects Good, reduce oil pipe wax deposition, small thermal conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

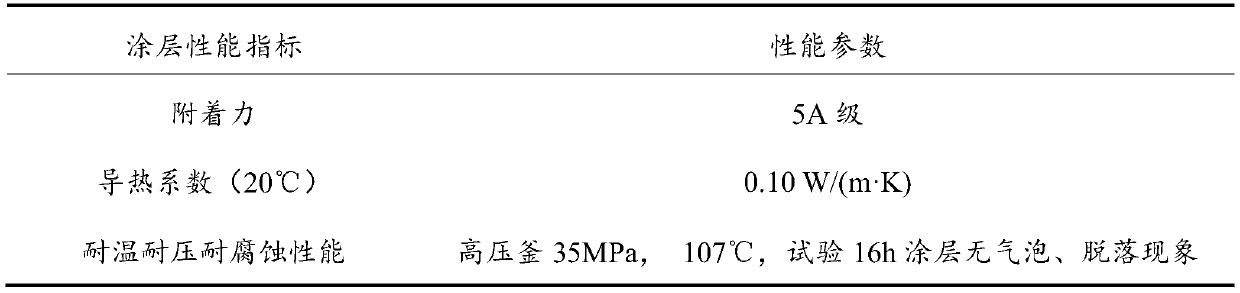

Examples

Embodiment 1

[0037] A kind of airgel composite coating, by weight parts, comprises following component:

[0038] 10 parts of silica gel powder, 50 parts of water-based epoxy resin, 10 parts of hollow glass microspheres, 5 parts of surface modifier, 3 parts of film-forming aid, 0.1 part of leveling agent and 1 part of defoamer;

[0039] Described surface modifier is prepared by following preparation method, and described preparation method specifically comprises:

[0040] 1) adding surface active monomer and sodium phosphate to polyacrylamide aqueous solution to obtain mixed solution A;

[0041] Wherein, the concentration of the polyacrylamide aqueous solution is 55%, and the mass ratio of the surface active monomer, polyacrylamide and sodium phosphate in the mixed solution A is 1:20:0.2;

[0042] 2) Adjust the pH value of the mixed solution A to 8 to remove oxygen;

[0043] 3) Send the mixed solution A after deoxygenation into the reactor, and within 30 minutes, heat up to 40°C, then add...

Embodiment 2

[0049] A kind of airgel composite coating, by weight parts, comprises following component:

[0050]10 parts of silica gel powder, 100 parts of water-based epoxy resin, 20 parts of hollow glass microspheres, 10 parts of surface modifier, 5 parts of film-forming aid, 1.0 part of leveling agent and 2 parts of defoamer;

[0051] Described surface modifier is prepared by following preparation method, and described preparation method specifically comprises:

[0052] 1) adding surface active monomer and sodium phosphate to polyacrylamide aqueous solution to obtain mixed solution A;

[0053] Wherein, the concentration of the polyacrylamide aqueous solution is 55%, and the mass ratio of the surface active monomer, polyacrylamide and sodium phosphate in the mixed solution A is 1:20:0.2;

[0054] 2) Adjust the pH value of the mixed solution A to 10 to remove oxygen;

[0055] 3) Send the mixed solution A after deoxygenation into the reactor, and within 30 minutes, heat up to 40°C, then ...

Embodiment 3

[0061] A kind of airgel composite coating, by weight parts, comprises following component:

[0062] 10 parts of silica gel powder, 80 parts of water-based epoxy resin, 15 parts of hollow glass microspheres, 8 parts of surface modifier, 4 parts of film-forming aid, 0.5 parts of leveling agent and 1.5 parts of defoamer;

[0063] Described surface modifier is prepared by following preparation method, and described preparation method specifically comprises:

[0064] 1) adding surface active monomer and sodium phosphate to polyacrylamide aqueous solution to obtain mixed solution A;

[0065] Wherein, the concentration of the polyacrylamide aqueous solution is 55%, and the mass ratio of the surface active monomer, polyacrylamide and sodium phosphate in the mixed solution A is 1:20:0.2;

[0066] 2) Adjust the pH value of the mixed solution A to 9 to remove oxygen;

[0067] 3) Send the mixed solution A after deoxygenation into the reactor, and within 30 minutes, heat up to 40°C, then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com