Coal chemical industry wastewater zero-discharge integrated treatment system and method

A technology of coal chemical wastewater treatment system, applied in oxidation water/sewage treatment, water/sewage treatment, aerobic process treatment, etc., can solve problems such as wastewater pollution, and achieve technically reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

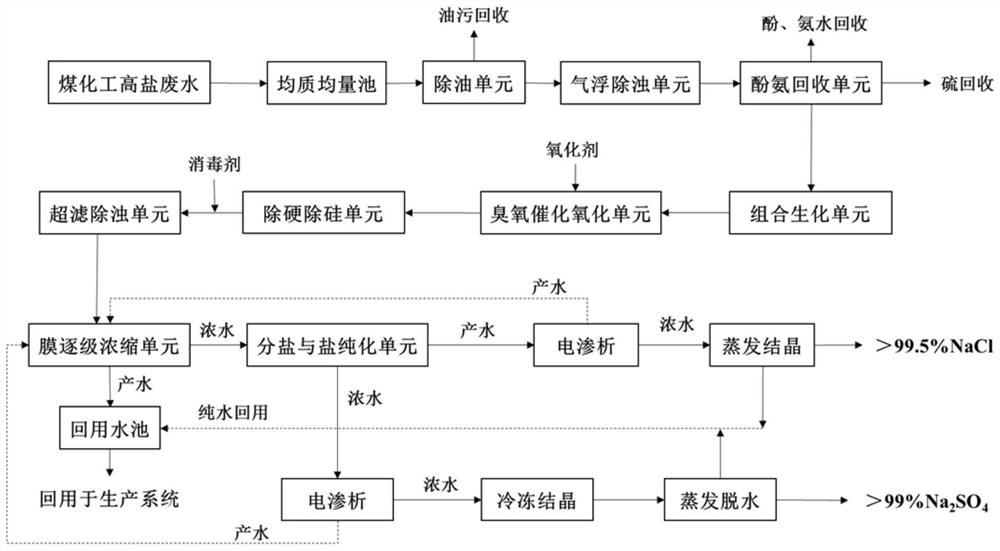

[0068] In this embodiment, coal-to-oil 300m 3 / h waste water as an example, carry out the application test, after 7 days of stable operation, carry out the water quality test, refer to the treatment process figure 1 and the following method. See Table 1 below for the quality of influent and effluent water.

[0069]S1: First, adjust the pH of coal-to-oil wastewater to about 6, use a closed grease trap to remove coal-to-oil tar, tar residue, slick oil and suspended solids from the wastewater, and the wastewater treated by the grease trap enters the demulsification process Add demulsifier and reverse phase demulsifier to the drug mixer to destroy the stability of the emulsified oil in the water, and the demulsified wastewater passes through a high-precision oil-water separator to complete the removal of residual oil in the wastewater.

[0070] S2: Pass the air into the waste water to form tiny air bubbles, so that the suspended particles in the waste water adhere to them and be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com