Dynamic supplementary spraying control system and method for spraying robot and breakpoint return control system and method

A spraying robot and control system technology, applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve problems such as the decline of the effect quality and the change of the thickness of the paint film, and achieve the effect of improving the spraying quality, improving the efficiency, and avoiding the damage of the spraying pipeline.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

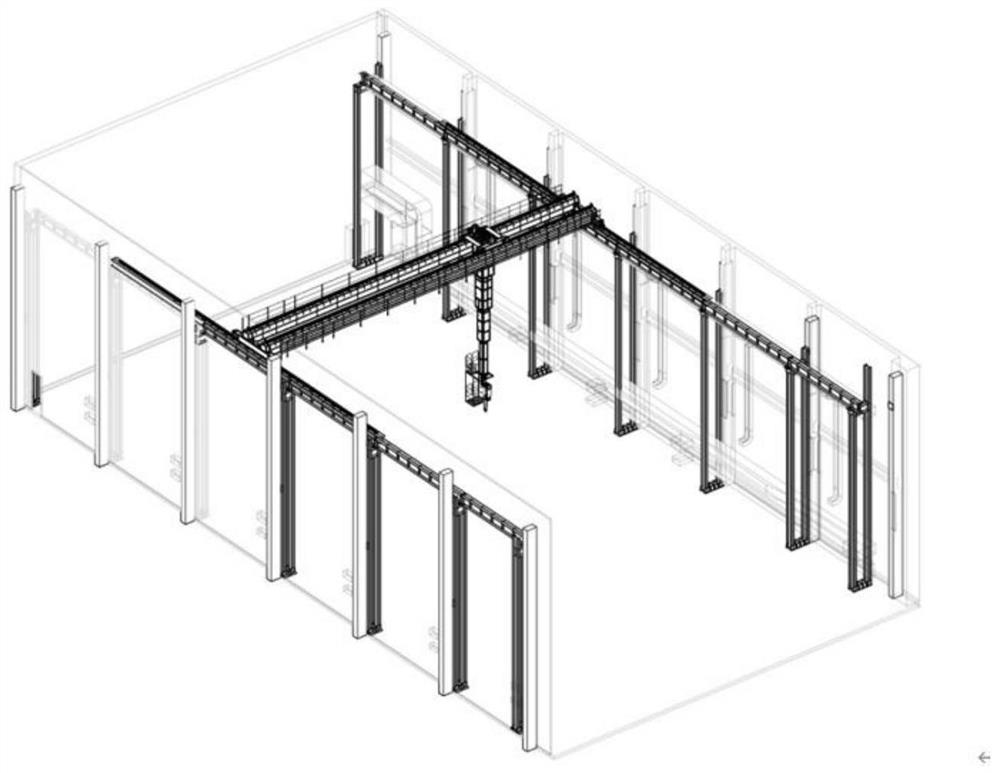

[0048] Such as figure 2 , Figure 8 and Figure 9 As shown, a kind of spraying robot dynamic supplementary spraying control system in this embodiment includes a spraying robot and a spraying target, and the spraying robot includes a spray gun for spraying, and a pressure sensor is set in the spray gun pipeline, and also includes a data acquisition module, a calculation module, a control module; the spraying system of the spraying robot in this embodiment adopts CP505 / A controller, robot controller, driver and servo motor, etc., and uses the Ethercat bus protocol to communicate, and completes the configuration of the spraying robot system, so as to set the breakpoint for the spraying robot spray gun The implementation of the method of recovery and dynamic respray provides the basis.

[0049] The configuration steps of the spraying robot spraying system are:

[0050] S1: Install the Ethercat communication module in the robot controller, activate the key of the Ethercat commu...

Embodiment 2

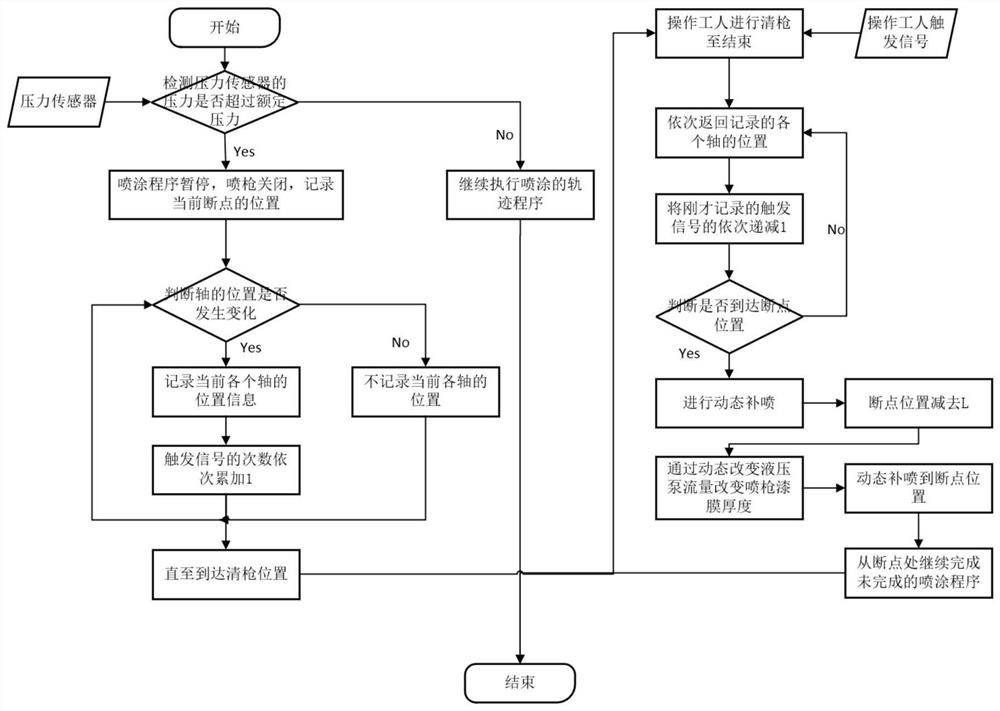

[0060] Such as figure 1 As shown, a method for controlling dynamic respraying of a spraying robot in this embodiment adopts the configuration and control system of the spraying system in the above embodiment, and the control method includes the following steps:

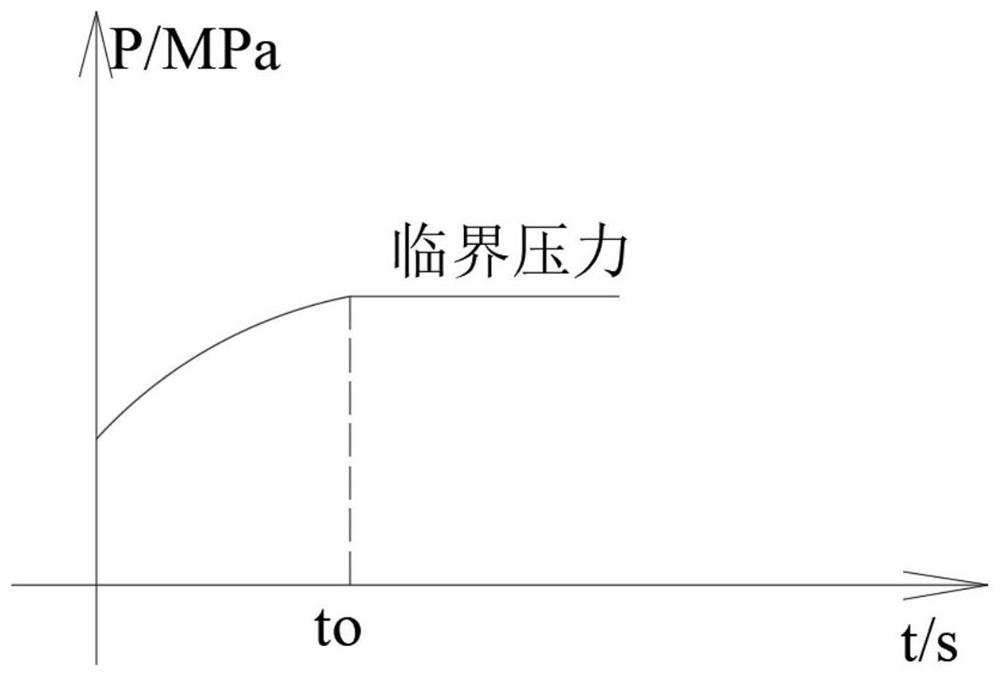

[0061] (1) When the spray gun of the spraying robot is blocked from the beginning to the complete blockage, due to the constant output power of the hydraulic pump, the cross-sectional area S of the spray gun nozzle decreases with time, and the pressure P in the pipeline increases with time. The pressure of the pressure sensor in the spray gun pipeline will rise slowly until it reaches the critical pressure. When the spray gun of the spraying robot is clogged, the real-time pressure data of the spray gun pipeline will be collected. The pressure change of the pressure sensor is as follows: figure 2 As shown, when the critical pressure is reached, the pressure sensor is triggered to send a signal to the PLC. According t...

Embodiment 3

[0080] A breakpoint restoration control system of a dynamic respray control system of a spraying robot in this embodiment, on the basis of the above-mentioned embodiment 1, also includes a position memory module, a counting module, a pathfinding module and a return control module, the position memory module is used After the spray gun of the spraying robot is blocked and closed, the position coordinates of the spraying robot are recorded in real time. The counting module is used to count the number of times the position memory module records the position coordinates. The pathfinding module is used for the spraying robot to return sequentially according to the position coordinates recorded by the position memory module. And at this time, the count of the counting module is decremented, and the return control module is used to send a return signal to the pathfinding module.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com