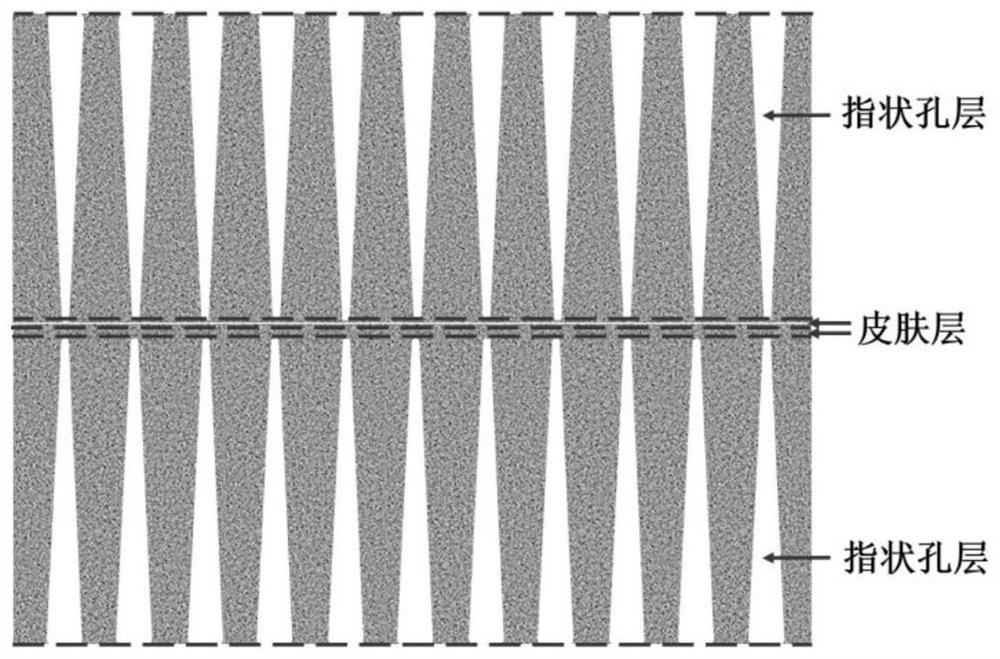

High-flux ceramic support body, preparation method and application thereof

A support and high-throughput technology, which can be used in ceramic products, applications, and other household appliances, etc., can solve problems such as strength decline, and achieve the effects of increased bending strength, high mass flux, and high application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for preparing a high-throughput ceramic support body, comprising the following steps: preparing ceramic slurry and sacrificial layer slurry respectively, and the proportioning ratio is shown in the following table:

[0033]

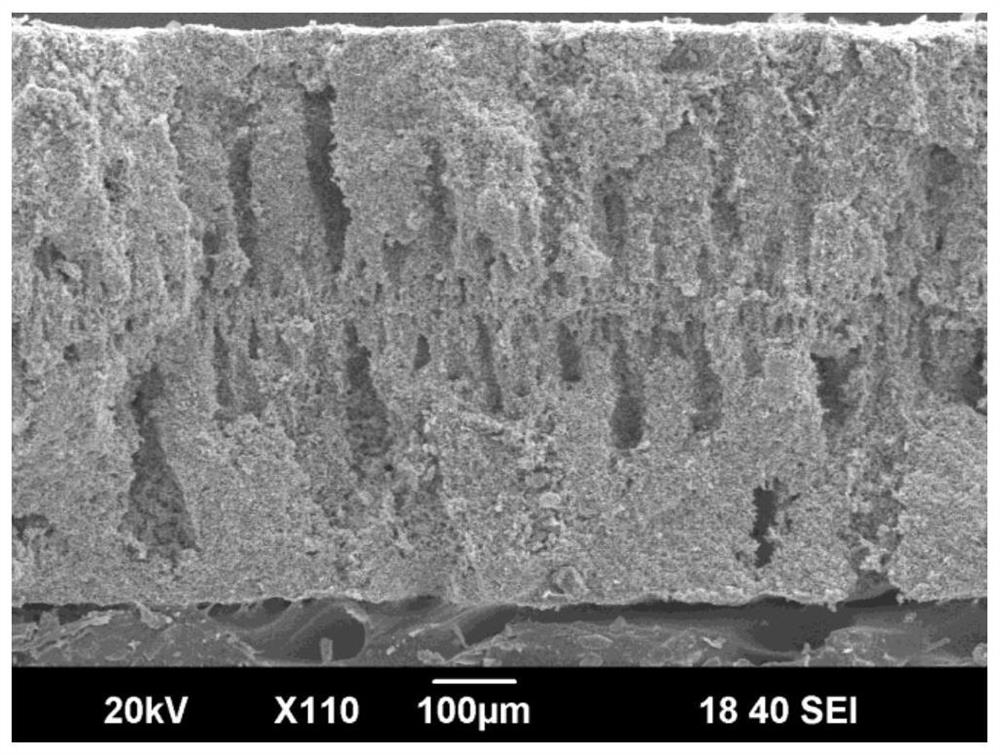

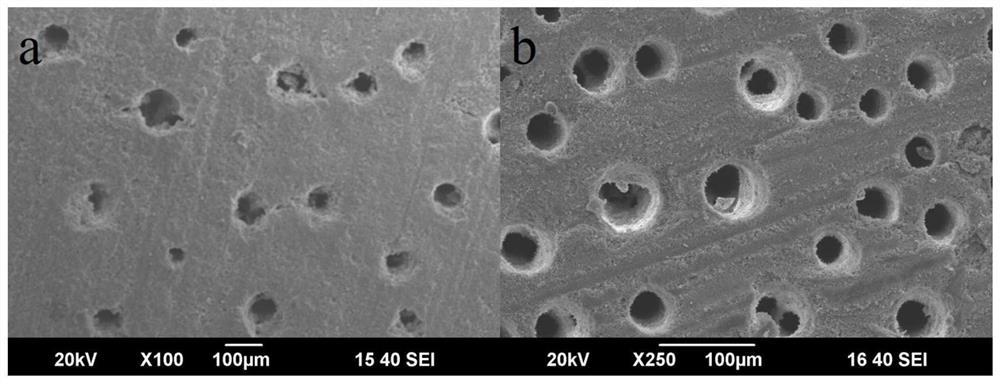

[0034] The prepared slurry is subjected to ball milling, the rotation speed of the planetary ball mill is 300r / min, and the ball milling time is 24h. Then use a double-layer scraper device to carry out a double-layer casting process, the total thickness of the casting is 1mm, the thickness of the upper layer of ceramic slurry is 0.85mm, and the thickness of the lower layer of graphite slurry is 0.15mm. The cast slurry was transferred to water for curing, and the curing time was 10 hours. The cured precursor was dried at room temperature for 3 days, and then cut into rectangles. After drying the ceramic precursor, gently wipe its upper surface with N-methyl-pyrrolidone, then stack the upper surfaces of the two films together, and use a ...

Embodiment 2

[0041] A method for preparing a high-throughput ceramic support body, comprising the following steps: preparing ceramic slurry and sacrificial layer slurry respectively, and the proportioning ratio is shown in the following table:

[0042]

[0043]

[0044]The prepared slurry is subjected to ball milling, the rotation speed of the planetary ball mill is 300r / min, and the ball milling time is 24h. Then use a double-layer scraper device to carry out a double-layer casting process, the total thickness of the casting is 1mm, the thickness of the upper layer of ceramic slurry is 0.85mm, and the thickness of the lower layer of graphite slurry is 0.15mm. The cast slurry was transferred to water for curing, and the curing time was 10 hours. Dry the cured precursor at room temperature for 3 days, and then cut it into the desired circle or rectangle. After drying the ceramic precursor, gently wipe its upper surface with N-methyl-pyrrolidone, then stack the upper surfaces of the t...

Embodiment 3

[0047] A method for preparing a high-throughput ceramic support body, comprising the following steps: preparing ceramic slurry and sacrificial layer slurry respectively, and the proportioning ratio is shown in the following table:

[0048]

[0049]

[0050] The prepared slurry is subjected to ball milling, the rotation speed of the planetary ball mill is 300r / min, and the ball milling time is 24h. Then use a double-layer scraper device to carry out a double-layer casting process, the total thickness of the casting is 1 mm, the thickness of the upper layer of ceramic slurry is 0.7 mm, and the thickness of the lower layer of graphite slurry is 0.3 mm. The cast slurry was transferred to water for curing, and the curing time was 10 hours. The cured precursor was dried at room temperature for 3 days, and then cut into circular shapes. After drying the ceramic precursor, gently wipe its upper surface with N-methyl-pyrrolidone, then stack the upper surfaces of the two films to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Three-point bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com