TPK desulfurized rubber powder/SBS composite modified asphalt and preparation method thereof

A technology of compound modified asphalt and desulfurized rubber powder, applied in building components, building insulation materials, buildings, etc., can solve the problems of reducing the high and low temperature performance of rubber asphalt, application limitations, and high SBS prices, and achieves improved compatibility, reduced The effect of performance, simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

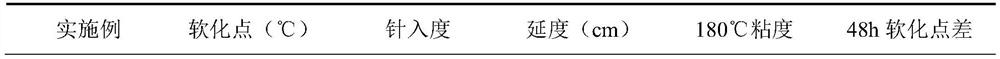

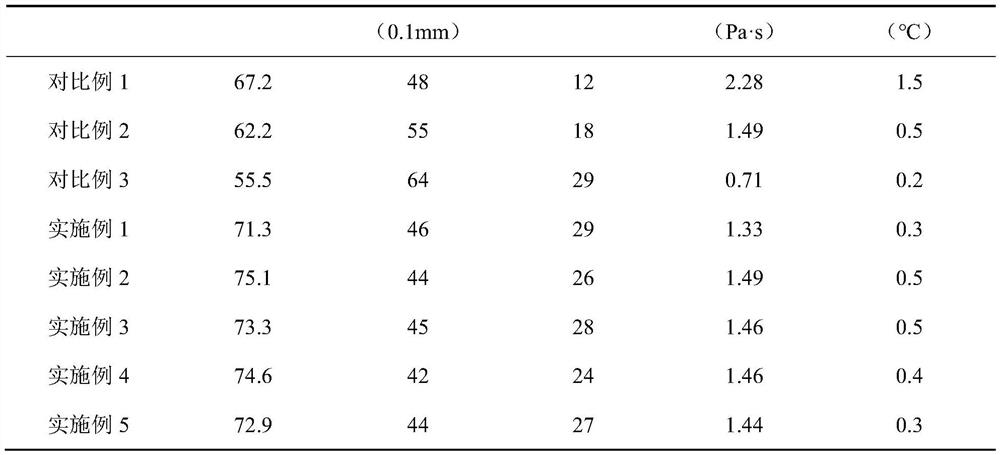

Embodiment 1

[0070] The TPK desulfurized rubber powder / SBS composite modified asphalt given in this example consists of the following raw materials in parts by weight: 78 parts of base asphalt, 13 parts of TPK desulfurized rubber powder, 1 part of SBS, 0.1 part of stabilizer, solubilizer 0.1 part and anti-aging agent 0.1 part.

[0071] The preparation method of the above-mentioned TPK desulfurized rubber powder / SBS composite modified asphalt is carried out according to the following steps:

[0072] Step 1, weighing each raw material respectively according to the mass proportion of the raw materials;

[0073] Step 2: Put the base asphalt in an oven at 150°C and heat it to a fluid state, take it out and put it on the heating equipment, and add SBS, stabilizer and anti-aging agent in sequence under stirring at 300r / min. Raise the temperature to 160°C within 5 minutes after the addition is completed and keep it for 30 minutes;

[0074] Step 3. Put the evenly stirred asphalt into an oven at 1...

Embodiment 2

[0081] The difference between this embodiment and the above-mentioned embodiment 1 lies in the ratio of each raw material. The TPK desulfurized rubber powder / SBS composite modified asphalt given in this example consists of the following raw materials in parts by weight: 83 parts of base asphalt, 17 parts of TPK desulfurized rubber powder, 3 parts of SBS, 0.8 parts of stabilizer, and 0.8 parts of solubilizer part and 0.8 part of anti-aging agent.

[0082] The preparation method of the above-mentioned TPK desulfurized rubber powder / SBS composite modified asphalt is carried out according to the following steps:

[0083] Step 1, weighing each raw material respectively according to the mass proportion of the raw materials;

[0084] Step 2: Put the base asphalt in an oven at 150°C and heat it to a fluid state, take it out and put it on the heating equipment, and add SBS, stabilizer and anti-aging agent in sequence under stirring at 300r / min. Raise the temperature to 160°C within 5...

Embodiment 3

[0092] The difference between this embodiment and the above-mentioned embodiment 1 lies in the ratio of each raw material. The TPK desulfurized rubber powder / SBS composite modified asphalt given in this example is calculated in parts by weight and consists of the following raw materials: 80 parts of base asphalt, 15 parts of TPK desulfurized rubber powder, 1.5 parts of SBS, 0.3 parts of stabilizer, solubilizer 0.3 parts and anti-aging agent 0.3 parts.

[0093] The preparation method of the above-mentioned TPK desulfurized rubber powder / SBS composite modified asphalt is carried out according to the following steps:

[0094] Step 1, weighing each raw material respectively according to the mass proportion of the raw materials;

[0095] Step 2: Put the base asphalt in an oven at 150°C and heat it to a fluid state, take it out and put it on the heating equipment, and add SBS, stabilizer and anti-aging agent in sequence under stirring at 300r / min. Raise the temperature to 160°C wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com