Integrated connected ecological frame

An ecological and conjoined technology, applied in the production of ceramic materials, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of hindering the growth of plant roots and the inability to realize the integration of soil and ecological walls.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

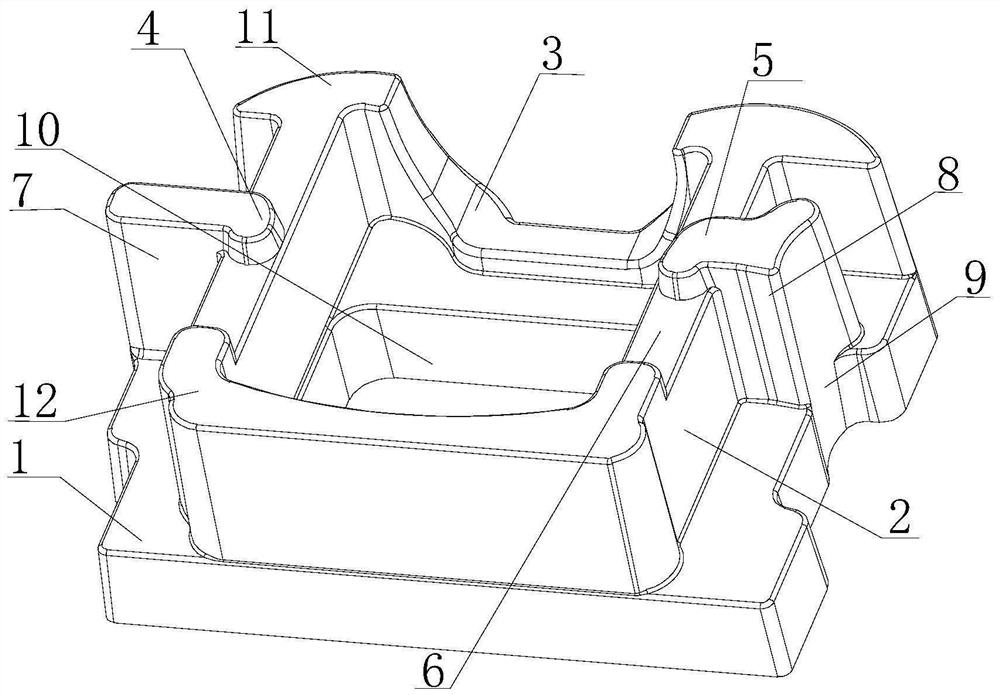

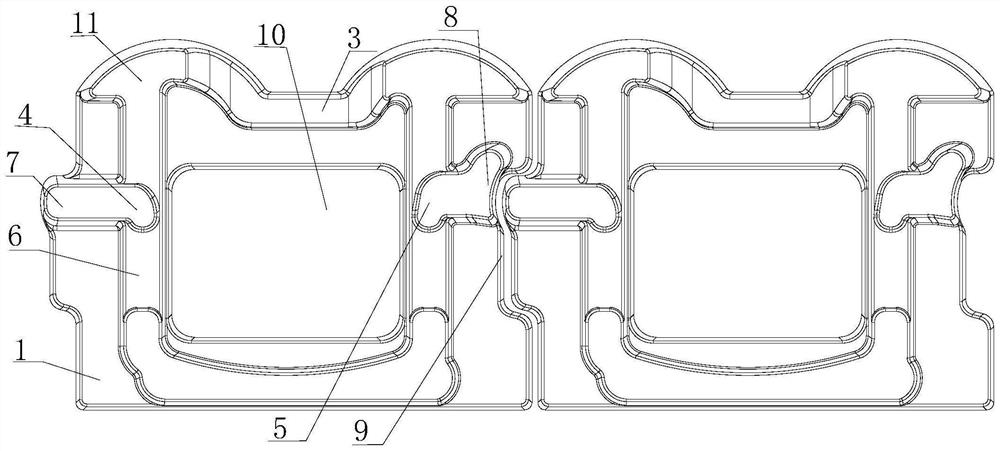

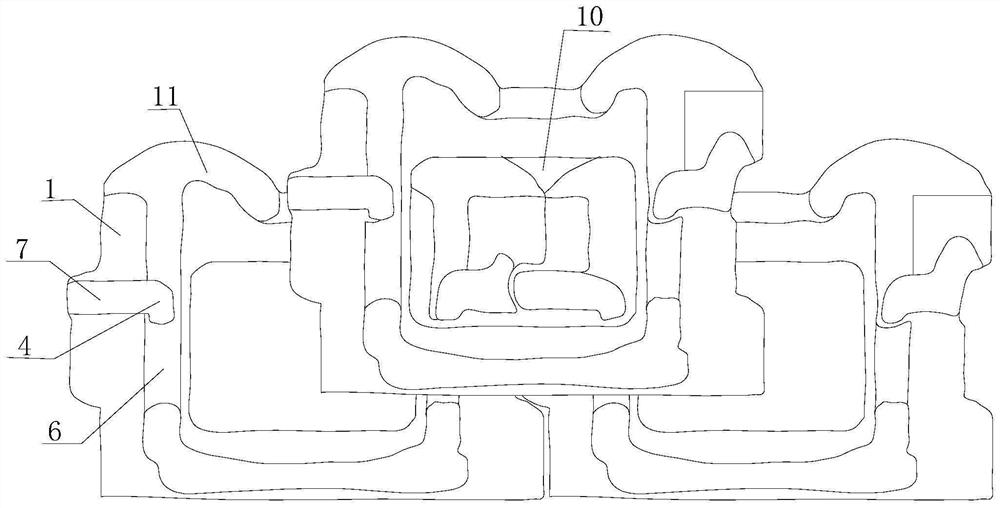

[0042] Such as Figure 1-7 As shown, this embodiment provides an integrated one-piece ecological frame, which includes a number of ecological block bodies that are clamped to each other in the horizontal direction, and ecological block bodies are dislocated between two adjacent ecological block bodies. The block body includes a base plate 1, an accommodation ring body 2 arranged on the base plate 1, a through-hole 10 opened on the base plate 1 and located inside the accommodation ring body 2, a groove 3 is opened at the front end of the top of the accommodation body, and the top left end of the accommodation ring body 2 Protrusion one 4 is provided, and the right end of the accommodation ring body 2 is provided with protrusion two 5, and the rear end of the top of the accommodation ring body 2 is provided with an annular ring body 12, between the protrusion one 4 and the annular ring body 12 there is The limit groove 6 is formed on the ring body 2, and the limit groove 6 is al...

Embodiment 2

[0048] A production device suitable for an integrated one-piece ecological frame, which includes a stirring box 13, a discharge port arranged at the bottom of the stirring box 13, a stirring assembly arranged in the stirring box 13 for stirring raw materials, and a stirring assembly arranged in the stirring box 13 The horizontal plate 21 on the top, the screening box 22 which is set on the horizontal plate 21 and hollowed out at the bottom, the scrap assembly which is arranged in the upper part of the screening box 22 for crushing raw materials, and which is arranged in the lower part of the screening box 22 to cooperate with the scrap assembly The screening assembly, the opening and closing door 60 arranged on the screening box 22 and used in conjunction with the screening assembly, and the conveying assembly arranged on the top of the outer wall of the screening box 22 for conveying raw materials.

[0049] The stirring assembly includes a stirring shaft 15 between the horizon...

Embodiment 3

[0054] A production method applicable to a production device suitable for an integrated conjoined ecological frame according to claim 5, characterized in that it comprises the following specific steps:

[0055] S1. Raw material preparation: prepare gangue soil, mine tailings, rock slag and industrial waste;

[0056] S2. Conveying raw materials: first start the conveying motor 39, so that the conveying motor 39 drives the conveying shaft 42 to rotate, and the conveying shaft 42 drives the screw blade 43 to rotate, and then conveys the raw material to the conveying cylinder 40 through the conveying hopper 41;

[0057] S3, crushing raw materials: while carrying out the S2 step, start the rotating motor 26, so that the rotating motor 26 drives the driving rod 27 to rotate, the driving rod 27 drives the driving gear 28 to rotate, the driving gear 28 drives the driven gear 29 to rotate, and the driven gear 29 Drive the rotating shaft 30 to rotate, and the rotating shaft 30 drives th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com