A kind of preparation method of silicon carbide ceramic tube

A silicon carbide ceramic and silicon carbide powder technology, applied in the field of engineering ceramic materials, can solve the problems of uneven distribution, low molding density, and high mold cost, and achieve the effects of uniform material, uniform powder, and high molding dimensional accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

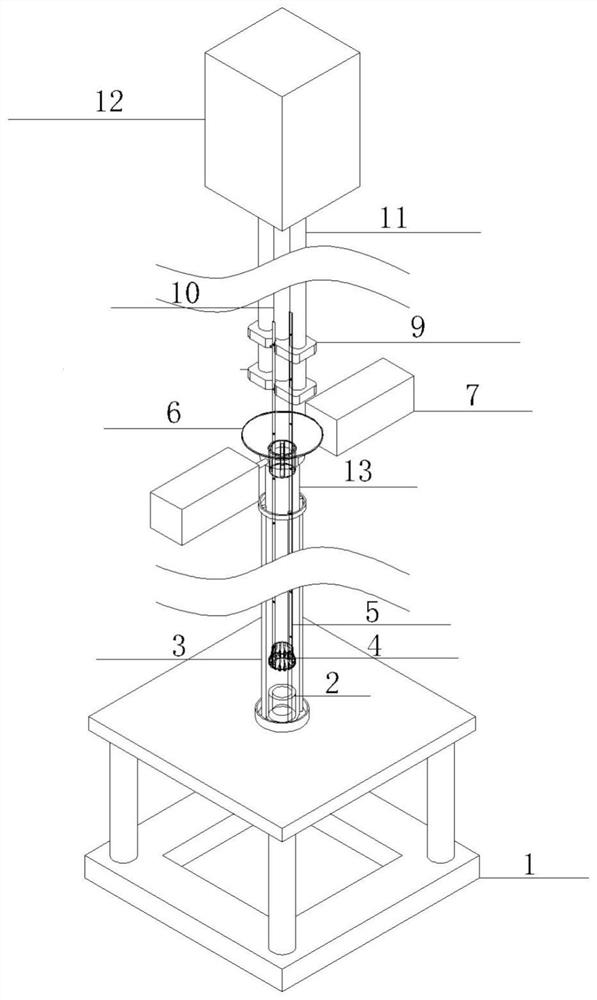

[0027] The present invention will be further described below in conjunction with accompanying drawing.

[0028] like figure 1 Shown, a kind of silicon carbide ceramic tube preparation method of the present invention comprises the following steps:

[0029] (1) Configuration powder

[0030] Prepare silicon carbide powder, sintering aids, binders, plasticizers, dispersants, and lubricants into filling powders;

[0031] (2) Device adjustment

[0032] Put the rubber sheath mold into the hanging basket 3, snap the centering sleeve 4 into the rubber sheath mold 13, put a mandrel through the centering sleeve 4 into the mould, and use the lower end cover 2 to snap into the rubber sheath mold 13 Inside and fastened with clamps;

[0033] (3) Powder filling

[0034] Insert the upper centering funnel 6 into the holster, open the positioning cylinder 7 to fix the rubber holster mold 13, fix the tie rod 5 holes to the pull plate 9, start adding powder, first move the pull plate 9 to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com