Multi-stage retarding device

A technology of a retarding device and a component, which is applied in the field of mechanical transmission and can solve the problems of large power consumption, large size, and inconvenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

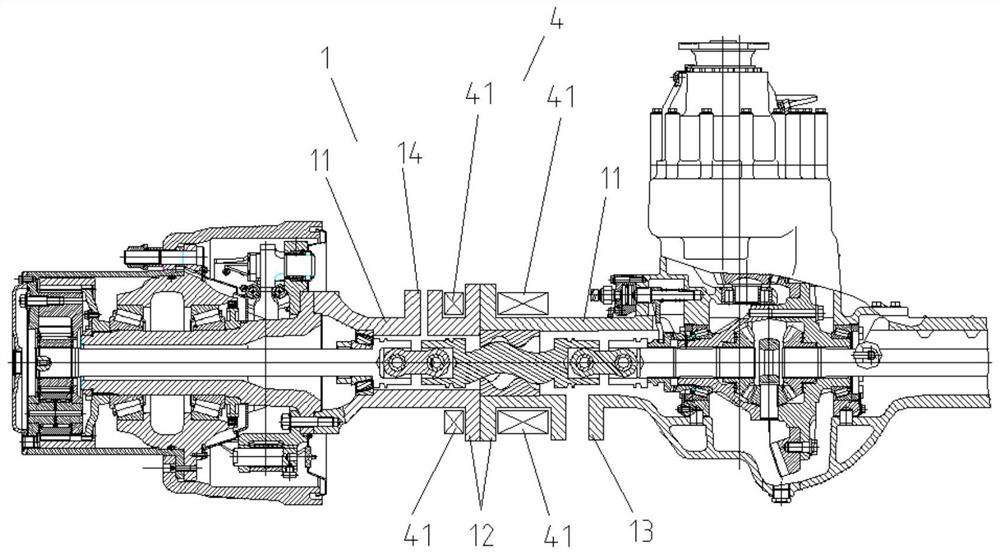

[0053] As an optional embodiment of the present invention, the rotor assembly 3 further includes a permanent magnet;

[0054] The permanent magnet is arranged at the main body of the positive displacement pump, and performs preliminary intervention on the magnetorheological fluid medium in the positive displacement pump; the electromagnetic coil 41 is arranged at the orifice, and convects the magnetic flow flowing through the orifice. The concentration of the variable fluid medium can be precisely regulated.

[0055] As an optional embodiment of the present invention, a limiting protrusion and / or a limiting groove are provided on the outer side of the sealing assembly;

[0056] The limiting protrusion runs through the electromagnetic coil 41 to prevent the electromagnetic coil 41 from slipping relative to each other;

[0057] The limiting groove accommodates the electromagnetic coil 41, the shape and size of the limiting groove match the electromagnetic coil 41, the electroma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com