Automatic packaging equipment for specific flexible dental floss

An automatic packaging and flexible technology, applied in packaging, transportation and packaging, storage devices, etc., can solve the problems of easy entanglement and knotting of dental floss, high failure rate, and low efficiency of manual collection of dental floss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

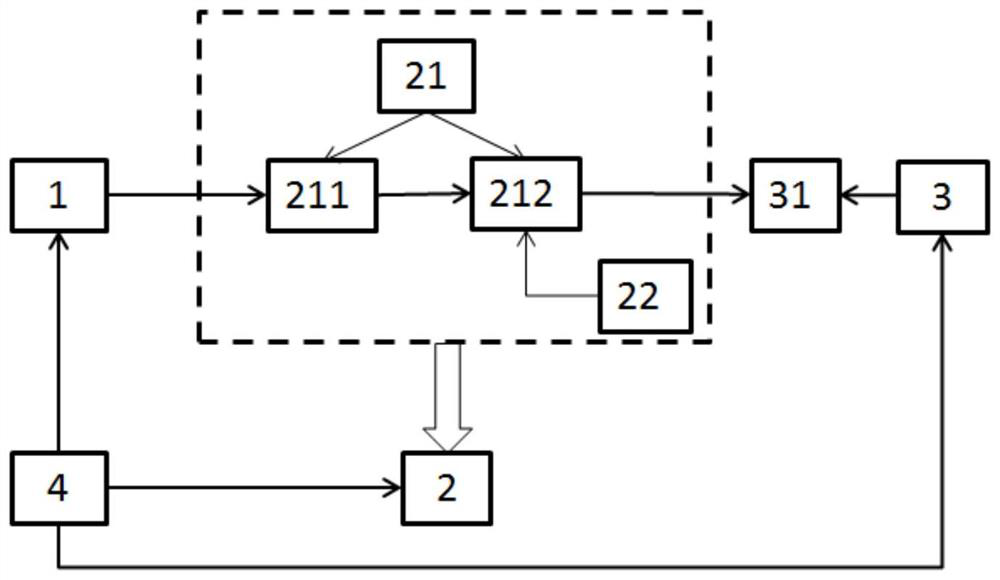

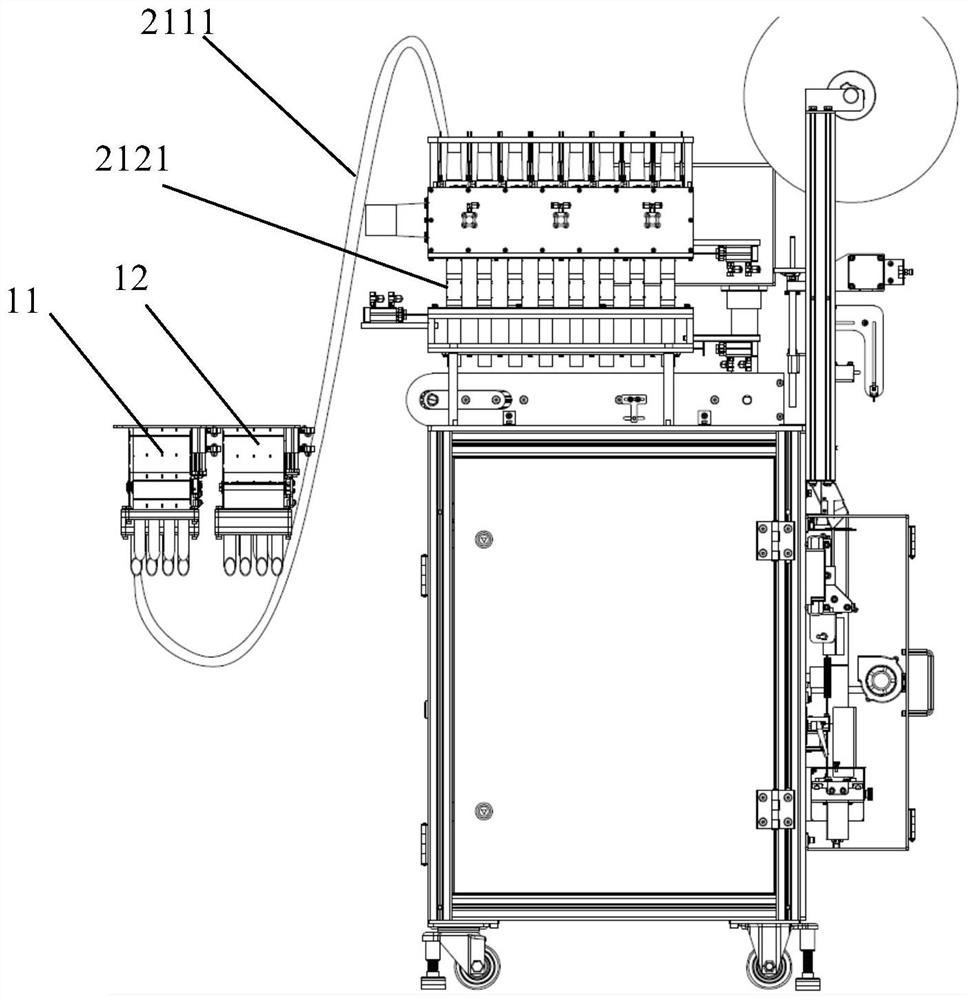

[0111] see Figure 1-Figure 4 , the application provides an automatic packaging device for specific flexible dental floss, including a receiving module 1, a conveying and folding module 2, a packaging module 3 and a central control module 4, wherein the packaging module 3 includes a conveyor belt 31; the receiving module 1 Constructed to receive the specific flexible floss delivered by the injection molding machine; the central control module 4 is configured to control the operation of the various modules.

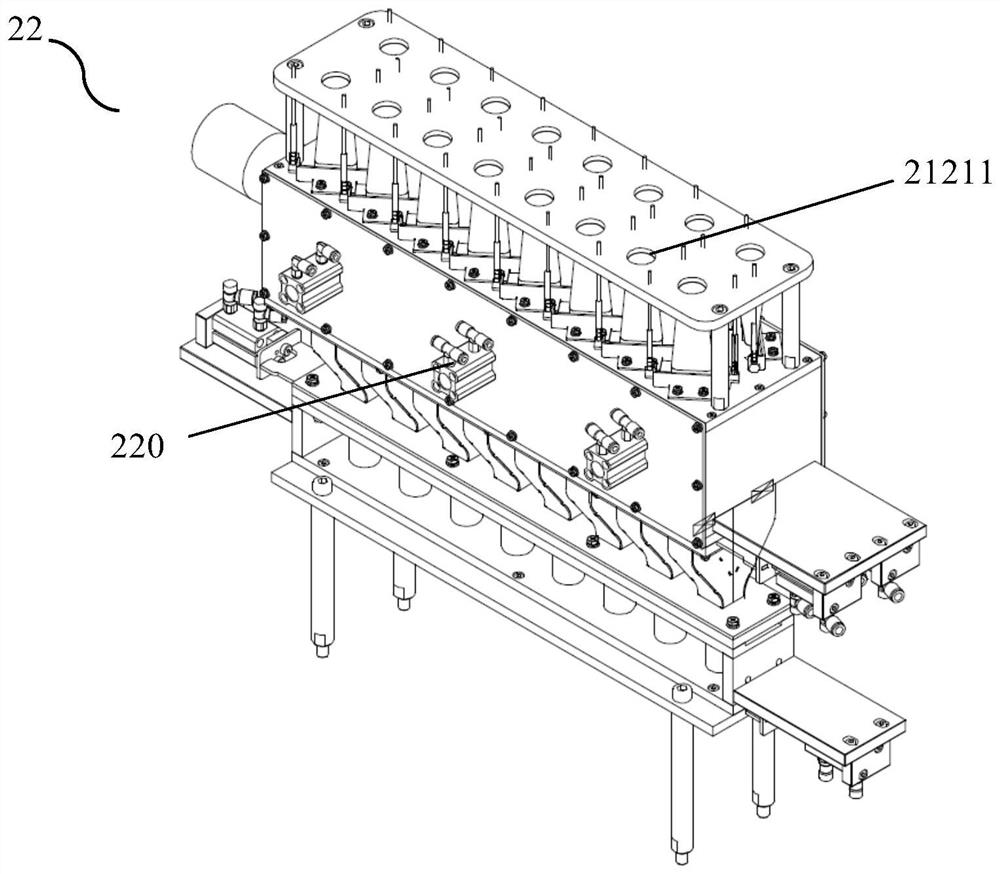

[0112] The conveying and folding module 2 includes a vacuum suction channel 21, a dispensing mechanism 22 and a negative pressure device. The vacuum suction channel runs through the conveying and folding module. The vacuum suction channel 21 includes a suction hose part 211 and a non-hose ingredient part 212. The non-hose ingredient part 212 is arranged in the distribution mechanism 22, and the vacuum suction channel 21 is used to transport the flexible dental floss to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com